Alarm Management

Yokogawa’s range of alarm management services are independent of vendor technology and based on our expertise in hands-on improvement. We implement a program that will help your team understand the concepts of good alarm management practice, plan for improvement and ultimately move beyond just managing alarms to using alarms to manage your safety, process and productivity.

Flexible and pragmatic approach

Alarm management is a journey with a destination that is unique for every plant. The alarm management services from Yokogawa reflect this in a flexible, comprehensive but pragmatic approach, tailored to your individual needs and circumstances. In summary the main steps span gap assessment, improving performance and finally steady, continuous improvement. In the vast majority of cases there are a number of quick wins.

Customer Challenge

Transforming an alarm system from an ineffective nuisance to a valuable asset.

An alarm system is often the first line of defence in avoiding a serious process incident, and yet all too often it is ineffective when it is needed most. Alarm floods, nuisance alarms and high numbers of standing alarms are all common features of a poorly configured alarm system leading to operators missing important alarms. At the other end of the spectrum a well-managed alarm system provides the operational clarity needed for optimal day-to-day operations and consistent performance.

Our Solutions

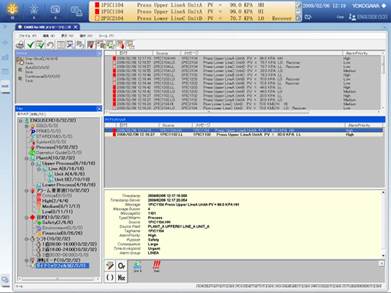

Our Experience Guides the Alarm Writing Process

Effective alarm management requires a humancentric approach to the challenges. Yokogawa’s alarm management program recognises this fact. It is suitable for clients wishing to achieve compliance with international standards including ISA 18.2 and IEC 62682 but is even more appropriate for organisations that recognise there is a prize beyond compliance. These organisations recognise that a well-configured alarm system is a significant asset in improving plant performance and safety.

Yokogawa’s alarm management program consists of nine main steps divided in three phases. Depending on the customer’s situation, the entry point into this program and the required steps can vary.

Efficiency of operations and by extension operational improvement projects, like alarm management, is becoming more and more important. While face-to-face consultancy engagements are still the norm, Yokogawa recognizes that it can be a challenge to organize meetings with cross-functional teams, especially if it also involves a lot of travel. Where practically possible, we also offer remote consultancy services organized around teleconferencing and all-digital tooling for many of the steps in the program.

Phase 1: The baseline

• Step 1 Create awareness

• Step 2 Gap analysis / assessment

• Step 3 Improvement plan & budget

Phase 2: Performance improvement

• Step 4 Alarm management philosophy & procedure documentation

• Step 5 Alarm review (rationalise & reprioritise)

• Step 6 Measurement & KPI reporting

• Step 7 ‘Bad actor’ analysis and remediation

Phase 3: Advanced alarm management

• Step 8 Abnormal event analysis / state-based alarm control

• Step 9 Production improvements through alarms

Customer Benefits

A high-quality alarm system improves safety and profitability.

Typical benefits are:

Safer plant operation

• Information is sent to the right people at the right time

• Prevent operator overload

• Alarms guide operators for faster response and mitigation

Efficient and Profitable operations

• More stable process and product quality

• Reduced unplanned downtime

• Reduced unplanned maintenance

Compliance

• Auditable compliance to international and local standards

• Reductions in operational insurance fees

Resources

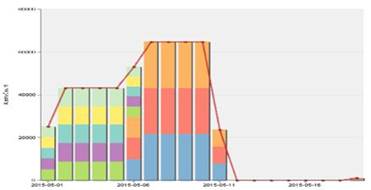

Alarm management is not just a project that has a start and end date; it's a continuous cycle. Once the alarm system has been reviewed and improvements have been identified, we must check that controls are in place to ensure the alarm system remains functional. The key is to ensure that the system is continuously monitored and any changes are fully documented. There are seven key steps for alarm management. Rationalization is one of those critical steps.

As plant operation becomes more intelligent and complex, the alarm system for safe and stable operation is becoming increasingly important. An alarm warns operators of an abnormal situation in a process and urges them to respond to it.

In recent years, safety and profitability have become ever more important in the process industry due to fierce global competition. Greater emphasis is being placed on highly efficient plant operation for reducing the increasing energy bill.

Videos

Dr. Maurice Wilkins - executive advisor at Yokogawa speaks with Alastair Greener from the Business Reporter at the Daily Telegraph and shares his thoughts on Process plant operators, automation and how they need to work together in a crisis.

Looking for more information on our people, technology and solutions?

Contact Us