Tokyo, Japan - April 19, 2022

Yokogawa Electric Corporation (TOKYO: 6841) announces that it will today release the Equipment/Quality Predictive Detection Tool. This addition to the OpreX™ Data Acquisition family is an AI-based tool for building equipment and quality anomaly predictive detection systems for GX series, GP series, and GM series SMARTDAC+™ paperless recorders and data loggers. With this software, even users who are not AI specialists will be able to build their own equipment and quality anomaly predictive detection systems for manufacturing sites. It will help them improve production efficiency by identifying equipment defects and deteriorating quality in their plants and other facilities at an early stage.

Equipment/Quality Predictive Detection Tool for SMARTDAC+

Zoom

Development Background

Recorders and data loggers are used at production and development sites in all kinds of industries to collect, display, and record data on voltage, current, temperature, flow rate, pressure, and other variables. As a leading company in this field, Yokogawa has provided many customers with data consulting services and technologies such as machine learning that can help them predict problems with plant equipment and product quality, and analyze and identify causes.

In recent years there has been a rising demand for AI-based solutions to improve production efficiency in plants. However, the hurdles for the application of AI are high as this requires significant expertise in specialized fields like data science. To address this need, Yokogawa has developed the Equipment/Quality Predictive Detection Tool, an easy-to-use AI-based software application for the recorders and data loggers that are commonly used in industry. To use this tool, no specialized AI expertise or consulting is required.

Features

- Predictive detection model can be created by AI based on existing record data without specialized knowledge

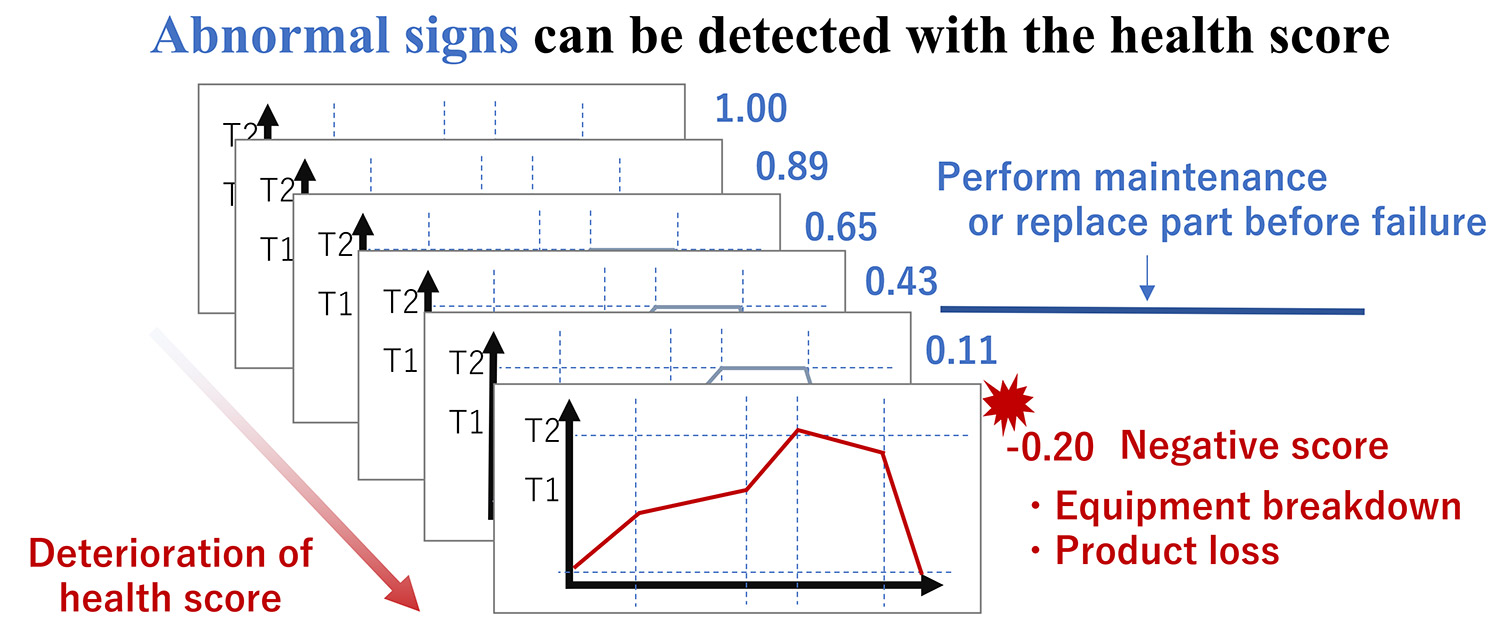

A predictive detection model can be created by importing past data into the software and simply flagging it as normal or abnormal, without needing to rely on an AI expert or consultant with knowledge about machine learning, algorithms, etc. Data recorded with Yokogawa and other companies' products can be used. Simulations can be run in advance to see how the AI assesses the data.

Simulation using a predictive detection model

Zoom - Using the predictive detection model, an equipment and quality predictive detection system can be easily built

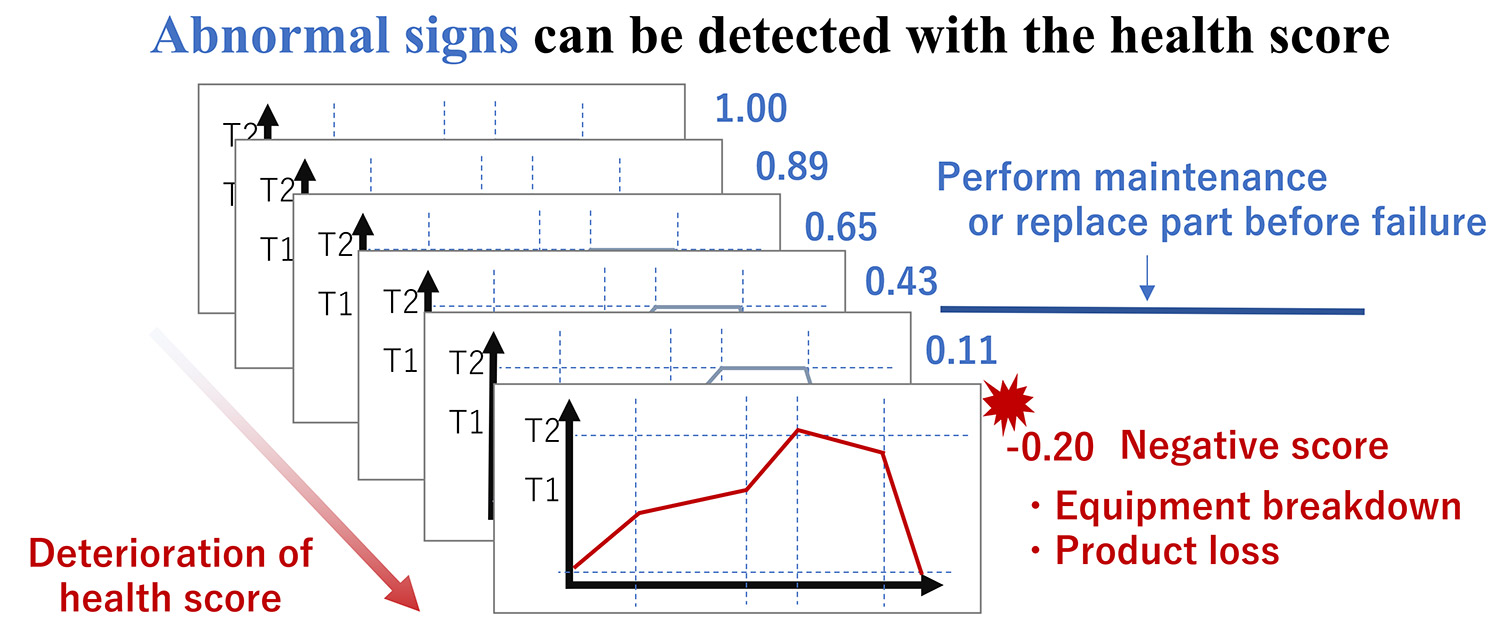

By loading the predictive detection model created by this software into the SMARTDAC+ on site, an equipment and quality anomaly predictive detection system can be constructed. The degree of equipment deterioration can be confirmed before failure by checking the health scores. These health scores enable operators to be informed by alarm or e-mail when equipment needs maintenance, minimizing the likelihood of an unexpected breakdown that can impact production activities.

Detecting problems at an early stage by monitoring changes in health scores

Zoom - Available in both cloud and offline versions

The Equipment/Quality Predictive Detection Tool will be available as both a cloud and an offline version. The equipment and quality anomaly predictive detection system can be built using either version. The cloud version is more easily available, and does not require any installations on a PC.

Sample Applications

- Managing temperatures and pressures in tire production (vulcanization)

Pressure leaks due to packing deterioration and so on are an issue with the vulcanizers that are used to apply heat and pressure to tire rubber. By using the Equipment/Quality Predictive Detection Tool to monitor changes in a health score that is generated based on a vulcanizer's pressure readings, signs of packing deterioration can be detected at an early stage. - Managing the thermal treatment of aerospace and automotive parts

In the thermal treatment of aircraft and automotive parts, issues like bad burners and inadequate sealing can lead to furnace downtime and poor product quality. The Equipment/Quality Predictive Detection Tool will enable signs of temperature problems to be detected before an alarm is triggered, so users can avoid product loss and predict when to perform maintenance. - Managing sterilization of food and drug products

With the vacuum sealing of food and drug products after they have been sterilized, unexpected equipment breakdowns can bring the production line to a halt and result in product loss. The Equipment/Quality Predictive Detection Tool will enable the detection of loose valves and packing deterioration before an alarm is triggered, so users can prevent equipment breakdowns and reduce product loss.

Major Target Markets

- Production sites for a broad range of industries, such as steel, power, chemicals, pulp & paper, food, pharmaceuticals, water and wastewater treatment, and electronics

- Consumer electronics, automobiles, semiconductors, and new energy development departments; university and public sector research institutions

Applications

Determination and quantification of production equipment and product quality deterioration

About SMARTDAC+

SMARTDAC+ stands for smart data acquisition and control, and the SMARTDAC+ system includes a variety of IO modules and options. With the product lineup of the GX series panel-mount type paperless recorders, GP series portable paperless recorders, GM series data acquisition systems, and GA10 data logging software, SMARTDAC+ offers extensive support for manufacturing process monitoring and performance evaluation.

About OpreX

OpreX is the comprehensive brand for Yokogawa's industrial automation (IA) and control business. The OpreX name stands for excellence in the technologies and solutions that Yokogawa cultivates through the co-creation of value with its customers, and encompasses the entire range of Yokogawa's IA products, services, and solutions. This brand comprises the following five categories: OpreX Transformation, OpreX Control, OpreX Measurement, OpreX Execution, and OpreX Lifecycle. The SMARTDAC+ data acquisition and control system is part of the OpreX Data Acquisition lineup, which is aligned under the OpreX Measurement category. The OpreX Measurement category includes field equipment and systems for highly precise measurement, data collection, and analysis.

About Yokogawa

Yokogawa provides advanced solutions in the areas of measurement, control, and information to customers across a broad range of industries, including energy, chemicals, materials, pharmaceuticals, and food. Yokogawa addresses customer issues regarding the optimization of production, assets, and the supply chain with the effective application of digital technologies, enabling the transition to autonomous operations.

Founded in Tokyo in 1915, Yokogawa continues to work toward a sustainable society through its 17,500 employees in a global network of 119 companies spanning 61 countries.

For more information, visit www.yokogawa.com

The names of corporations, organizations, products, services, and logos herein are either registered trademarks or trademarks of Yokogawa Electric Corporation or their respective holders.

Related Products & Solutions

-

AI Product Solutions

We have been solving customers’ issues in many industries using our AI. Utilizing our analysis experience and elemental technologies, we can offer a lineup of easy-to-use AI products. AI functions such as predictive detection and future prediction can be easily applied, and operation efficiency is improved.

-

Modular GM10

For industrial and lab applications, the GM10 offers Bluetooth wireless connection and modular I/O that offers accurate and reliable measurements.

-

Touch Screen GP10/GP20

SMARTDAC+TM GP10/GP20 is a paperless recorder that provides intuitive, human-centric design, web-enabled functionality, and scalable architecture.

-

Touch Screen Paperless Recorder GX10/GX20

The SMARTDAC+TM GX10/GX20 is a panel mount paperless recorder with a modular architecture on the back panel and has a data logging function to acquire the required data. By supporting not only I/O but also many communication protocols, you can connect to various devices. GX utilizes AI. Supporting FDA 21 CFR Part11 and AMS2750E/NADCAP.