Introduction

Level transmitter configuration can be very time consuming. Calculations required to determine proper range values for traditional transmitters can become complex due to the physical layout of an application.

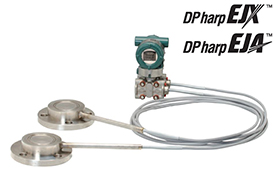

DPharp transmitters with advanced software functionality eliminate this time consuming task. With maintenance shops getting smaller, finding equipment that allows us to do more with less becomes a priority.

Application

Using typical smart or conventional products all of the following must be considered:

- The specific gravity (SG) of the process;

- Precise location of 0% and 100%;

- Specific gravity of the capillary fill fluid or sealing liquid (for impulse tubing);

- Vertical height of capillary or impulse piping;

- Exact orientation of the transmitter to the vessel;

- Vertical distance between the flanges.

Depending on the application, the vessel may be open (referencing atmosphere), or closed (under some blanket pressure).

Elevation is typically used when the vessel is closed. To reference blanket pressures, a low side wet leg or remote seal must be used. The low side pressure creates a negative force on the transmitter equal to the vertical height times the specific gravity of the fill fluid.

Suppression is positive pressure created on the high side of the transmitter typically due to a zero point above the transmitter. It is normally employed in an open vessel referencing atmosphere. This is a positive pressure equal to the vertical distance between the 0% point and the transmitter times the specific gravity of the liquid.

Elevation/suppression distance almost never agrees with the piping and instrumentation diagram (P&ID) because actual piping (or remote seal capillaries) do not form exacting angles in the field. In most cases, the precise vertical height is not known until the unit is installed.

Span is the vertical distance of the process times the specific gravity: Figure 1. 10.5 * 0.9 = 9.45 mH2O (31.5 inH2O).

Calibration range is the calculated 0 and 100% taking into consideration positive and negative pressures. In figure 1, the following applies:

Figure 1

0 % = H - L

= ( 4.5 x 0.8 ) - ( 15 x 0.8 )

= 3.6 - 12

= -8.4 mH2O ( -28 inH2O )

100 % = H - L

= ( 4.5 x 0.8 ) + ( 10.5 x 0.9 ) - ( 15 x 0.8 )

= 3.6 + 9.45 - 12

= 1.05 mH2O ( 3.5 inH2O )

The calibration range is: -8.4 to 1.05 mH2O ( -28 to 3.5 inH2O )

Note: SG stands for specific gravity.

The information required to perform the calculation is not readily available. It exists in vendors instruction manuals, P&ID's, but not until the unit is actually installed will all the variables be known because the process piping and capillaries do not form exacting angles in the field.

Solution

DPharp has a smart level setup feature that eliminates the need for elevation/suppression calculations, making set up quick and painless.

Calibration is accomplished by simply following these four steps (for Brain):

- Span the transmitter to the process, height * specific gravity of 0 to 9.45 mH2O (0 to 31.5 inH2O) using the BT200 in C21: LRV and C22: HRV.

- Install to the process using either capillaries or impulse tubing.

- Bring the process to a zero (4mA) condition.

- Through the BT200 execute H10: Auto LRV in the H: AUTO SET menu.

DPharp will calculate the total elevation/suppression and automatically setup the device for that installation. It will even correct the values in software at C21: LRV -28 and C22: HRV 3.5 so the customer can print and record the actual configuration for their maintenance documents.

But what if I cannot bring my process to zero? I have installed the unit, fluid is now in the tank, and the output of the transmitter does not agree with my sight glass. What do I do?

Most transmitters can only make adjustments at 0% or 100%. DPharp can make adjustments anywhere with full elevation or suppression. Once the transmitter is programmed with the correct span, all that is needed is a known point in the process (usually provided by the sight glass.) The output can be adjusted in one of two ways.

- Simply adjust the encoder on the DPharp until the output reaches the known point. In figure 1, the output would be adjusted to 60%.

- The correct value can be entered into J10: Zero Adj. In the case of this example, the proper output value of 60% would be entered. The amount of deviation can be viewed in J11: Zero Dev.

DPharp's digital sensing technology makes this possible. With analog sensing technologies (like capacitance sensors), range changes often necessitate a re-calibration or a trimming of the A/D converter to achieve specified performance. The digital DPharp sensor has no A/D converter, no trimming is necessary. The new range is guaranteed to perform within specification.

Notes

- In level measurement, it is important to maintain a consistent reference pressure. On a closed tank system, this is most efficiently achieved by the use of remote seals and capillary systems.

- It is important to note that the span is to be calculated on process height x specific gravity of the process fluid, and will not necessarily agree with the physical height.

- Output will be linear to the level, regardless of fluid or blanketing system.

- Use of remote seals eliminates problems such as condensation in impulse piping, the requirement for maintenance of condensate pots and fill fluid leaking into the process.

Main Features of DPharp

- ±0.03% Overpressure calibration protection

- ±0.1% per 10years long term stability

- 100:1 turndown

- ±0.055% accuracy

- SIL2 standard

- ±0.1% per 15years long term stability

- 200:1 turndown

- Best-in-class high accuracy, 0.04%

- Multi-sensing output

- Multi-variable transmitter as EJX family line-up

- SIL2 standard

Industrieën

-

Chemie

Chemische fabrieken zijn afhankelijk van continu- en batch-productieprocessen die elk verschillende eisen stellen aan een besturingssysteem. Een continu proces vereist een robuust en stabiel besturingssysteem dat niet faalt en de productielijn doet stilvallen. Bij een batchproces ligt de nadruk ligt op een besturingssysteem dat een grote flexibiliteit biedt bij het aanpassen van o.a. formules en procedures. Beide soorten systemen moeten worden beheerd naar aanleiding van de productiegeschiedenis rond de kwaliteit van het product, en in staat zijn om niet-routinematige werkzaamheden uit te voeren. Met een uitgebreide productportfolio, ervaren systeemingenieurs en wereldwijde verkoop- en servicenetwerk heeft Yokogawa een oplossing voor elk fabrieksproces.

-

Downstream olie & gas

De downstream olie- en gasindustrie wordt de laatste jaren met een toenemend aantal uitdagingen geconfronteerd. Deze omvatten de veranderende kenmerken van de te verwerken grondstoffen, veroudering van procesinstallaties en apparatuur, stijgende energiekosten, gebrek aan geschoolde fabrieksoperators die een raffinaderij veilig en efficiënt kunnen leiden en de steeds veranderende eisen van zowel de markt als de klant.

In de loop der jaren is Yokogawa een samenwerkingsverband aangegaan met vele downstream bedrijven om industriële oplossingen te bieden die gericht zijn op het oplossen van deze uitdagingen en problemen. Yokogawa's oplossingen hebben plantmanagers geholpen om maximale winstgevendheid en duurzame veiligheid binnen hun fabrieken te realiseren.

-

Energie

Halverwege de jaren zeventig deed Yokogawa zijn intrede in de energiebranche met de introductie van het EBS Electric Control System. Sindsdien is Yokogawa gestaag doorgegaan met de ontwikkeling van technologieën en mogelijkheden om onze klanten wereldwijd de beste diensten en oplossingen te bieden.

Yokogawa zet het internationale Network Power Solutions (NPS) in om een actievere rol te spelen in de dynamische wereldwijde energie markt. Dit heeft nauwere samenwerking binnen Yokogawa mogelijk gemaakt, waarbij onze wereldwijde middelen en industriële knowhow worden samengebracht. Yokogawa's experts in de energie-industrie werken samen om elke klant de oplossing te bieden die het beste past bij hun geavanceerde wensen.

-

IJzer en staal

In de ijzer- en staalindustrie is het van cruciaal belang om niet alleen de kwaliteit van producten te verbeteren, maar ook de productie- en bedrijfstechnologieën en om milieu- & energie-efficiëntievraagstukken aan te pakken. Yokogawa helpt klanten bij het creëren van de ideale fabriek en evolueert met hen mee voor wederzijdse groei.

-

Olie & gas

Yokogawa heeft diepgaande ervaring in elk deel van de olie- en gasindustrie. Van offshore- en onshore-installaties tot pijpleidingen, terminals en diepwateractiviteiten. Wij leveren oplossingen die de veiligheid verhogen, een nauwkeurige en betrouwbare werking garanderen en de efficiëntie van de installatie verhogen.

-

Water en afvalwater

Waterbronnen zijn eindig en daarom is het bijdragen aan een duurzame watercyclus een van de duurzame ontwikkelingsdoelen (SDG's). Yokogawa levert al jaren geavanceerde digitale besturingsoplossingen voor de stabiele levering van schoon en veilig water en de behandeling van afvalwater ter bescherming van het watermilieu. Maar ook het beheren van waterverliezen en de optimalisatie van de werking van installaties ter vermindering van de CO2-uitstoot en de bedrijfskosten.

Yokogawa ondersteunt een breed scala aan waterbesturingstoepassingen in zowel waterschappen als de industriële watermarkt. Met onze toonaangevende technologieën, betrouwbare producten, uitgebreide expertise en ervaring met diverse waterprojecten over de hele wereld, werken wij met u samen om duurzame wateroplossingen te bieden die uw bedrijf een impuls geven en waarde toevoegen gedurende de gehele levenscyclus van de installatie.

Gerelateerde producten & oplossingen

-

EJA110E

Standard Traditional-mount Differential Pressure Transmitter based on the EJA-E Series.

-

EJA115E

Standard Differential Pressure Transmitter attached to an IFO assembly based on the EJA-E Series.

-

EJA118E

Standard Differential Pressure Transmitter with Remote Diaphragm Seals based on the EJA-E Series.

-

EJA120E

Standard Traditional-mount Differential Pressure Transmitter designed for Draft Range applications based on the EJA-E Series.

-

EJA130E

Standard Traditional-mount High Static Differential Pressure Transmitter based on the EJA-E Series.

-

EJA210E

Standard Flange-mounted Differential Pressure Transmitter designed for Liquid-level applications based on the EJA-E series.

-

EJA310E

Standard Traditional-mount Absolute Pressure Transmitter based on the EJA-E Series.

-

EJA430E

Standard Traditional-mount Gauge Pressure Transmitter based on the EJA-E series.

-

EJA438E

Standard Gauge Pressure Transmitter with Remote Diaphragm Seal based on the EJA-E Series.

-

EJA440E

Standard Traditional-mount High Gauge Pressure Transmitter based on the EJA-E Series.

-

EJA510E

Standard In-Line Mount Absolute Pressure Transmitter based on the EJA-E Series.

-

EJA530E

Standard In-Line Mount Gauge Pressure Transmitter based on the EJA-E Series.

-

EJX110A

Traditional-mount Differential Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX115A

Differential Pressure Transmitter attached to an IFO assembly based on the EJX-A Series as a high performance model.

-

EJX118A

Differential Pressure Transmitter with Remote Diaphragm Seals based on the EJX-A Series as a high performance model.

-

EJX120A

Traditional-mount Differential Pressure Transmitter designed for Draft Range applications based on the EJX-A Series as a high performance model.

-

EJX130A

Traditional-mount High Static Differential Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX210A

Flanged-mounted Differential Pressure Transmitter designed for Liquid-level applications based on the EJX-A Series as a high performance model.

-

EJX310A

Traditional-mount Absolute Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX430A

Traditional-mount Gauge Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX438A

Gauge Pressure Transmitter with a Remote Diaphragm Seal based on the EJX-A Series as a high performance model.

-

EJX440A

Traditional-mount High Gauge Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX510A

In-Line Mount Absolute Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX530A

In-Line Gauge Pressure Transmitter based on the EJX-A Series as a high performance model.

-

EJX610A

High Performance In-Line Mount Absolute Pressure Transmitter based on the EJX-A Series.

-

EJX630A

In-Line Mount High Performance Gauge Pressure Transmitter based on the EJX-A Series.

-

EJX910A

This transmitter precisely measures differential pressure, static pressure, and process temperature; then uses these values in a high-perfomance on-board flow computer to deliver fully compensated Mass Flow.

-

EJX930A

Designed specifically for high static pressure applications, this transmitter precisely measures differential pressure, static pressure, and process temperature; then uses these values in a high-perfomance on-board flow computer to deliver fully compensated Mass Flow.

-

EJXC40A (Digital Remote Sensor)

Digital Remote Sensor (DRS) Transmitter connects two pressure sensors, primary (high-pressure side) and secondary (low-pressure side) in a remote location, with DRS dedicated communication cable to measure differential pressure.

-

EJXC50A, EJAC50E (Gauge Pressure Direct Mounted Seal)

Direct Mounted Diaphragm Seal System consists of gauge pressure transmitter with single direct mount diaphragm seal.

-

EJXC80A, EJAC80E (Differential / Gauge Pressure Diaphragm Seal)

Diaphragm Seal System consists of differential pressure or gauge pressure transmitter with one or two diaphragm seal.

-

EJXC80A, EJAC80E (Differential Pressure Direct Mounted Seal)

Direct Mounted Diaphragm Seal System consists of differential pressure transmitter with single direct mount diaphragm seal.

-

EJXC81A, EJAC81E (Absolute Pressure Diaphragm Seal)

Absolute Pressure Diaphragm Seal System consists of absolute pressure transmitter with single diaphragm seal.

-

Absolute Pressure

Absolute Pressure transmitters compare a pressure relative to Absolute pressure. Absolute pressure is always a positive value.

-

Diaphragm Seal System

Diaphragm Seal System can be used to measure liquid, gas, or steam flow as well as liquid level, density, and pressure.

-

Differential Pressure

Differential Pressure (DP) is defined as the difference between two pressures. Differential Pressure Transmitters use a reference point called the low-side pressure and compare it to the high-side pressure. Ports in the instrument are marked high-side and low-side.

-

Draft Pressure

Draft Pressure transmitters are a unique type of differential transmitter that is designed to measure small differences in very low static pressure environments.

-

Gauge Pressure

Gauge Pressure transmitters compare a pressure relative to atmospheric measure.

-

Hygienic Pressure Transmitters

Hygienic Pressure Transmitters are designed to fulfil the requirements of hygienic and pharmaceutical application.

-

Liquid Level

Accurate level readings are essential to the safe, reliable, profitable operation of your plant. Liquid Level transmitters measure differential pressure to infer the level in a vessel.

-

Low Flow

Using Bernoulli's equation, Differential Pressure transmitters can be used to infer the flow of fluid through a pipe.

-

Mass Flow (Multivariable)

There are several technologies on the market to measure mass flow. One is the Multi-variable Pressure Transmitter.

-

Pressure Transmitters

The accurate and stable measurement of process pressure with Yokogawa Pressure Transmitters supports the safe, reliable, and profitable operation of your plant.