Introduction

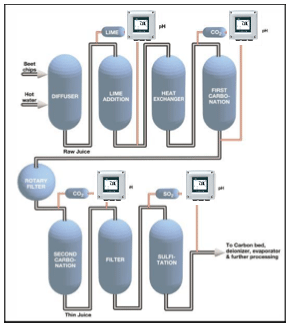

After extraction from sugar cane or sugar beets, juice must be purified to remove the many other organics and minerals that accompany it. The processing to accomplish this is heavily dependent on reliable pH measurement and control as illustrated.

The process for refining raw sugar cane or sugar beets includes the following steps: washing, crushing, extraction, liming, carbonation, filtering, and addition of sulfur dioxide, concentrating, crystallizing and drying. Of these various steps the most critical are: liming, carbonation and the addition of sulfur dioxide. Each of these steps requires continuous pH control.

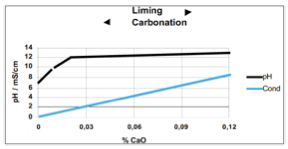

Lime Addition

Thorough washing of the sugar cane or beets is followed by crushing or cutting into chips and counter-current extraction of the sugar by hot water in a diffuser. The resulting "raw juice" is treated with alkaline 'milk of lime' (calcium hydroxide (CaOH) slurry), based on pH controlling to a set point of 11.0 to 11.5 pH.

The purpose of adding Lime is threefold:

- Neutralize acids in the cane of beets, thereby preventing the sucrose from turning into starch (hydrolysis) or other forms of sugar (inversion).

- Precipitate the organic acids into salts for subsequent removal.

- Keeping foreign matter (insoluble organics, proteins, etc.) in suspension until a filtration process can remove them.

Carbonation

All traces of lime must be removed before the concentration step to prevent scale buildup. Carbon dioxide, therefore, is added to the juice to precipitate the lime as less soluble calcium carbonate (limestone), which also tends to capture other impurities during precipitation. CaO + CO2 = CaCO3 (solid).

The sugar solution is heated and carbon dioxide is added by pH control. Optimum purification is achieved through two stages of carbonation to avoid an unmanageable type of precipitate that can develop in single stage carbonation. Close pH control is necessary at each stage to assure maximum removal of both impurities and calcium. By the last stage the pH should be reduced to about 9. After carbonation the juice is filtered to remove all traces of solid particles before transported to the sulfitation tower.

Add of Sulfur Dioxide (Sulfitation)

The juice is maintained at high temperatures and treated with sulfur dioxide to lower the pH to roughly 5-6 before it goes on to the evaporators. The sulfur dioxide also bleaches the juice to improve flavor and texture. Without this step an alkaline juice would be produced. The sugar crystals would stick together due to moisture absorption and have an undesirable taste. Again, pH control is essential to efficient operation. The sugar juice is then heated to drive off any residual gases and provide a neutral product.

The juice is maintained at high temperatures and treated with sulfur dioxide to lower the pH to roughly 5-6 before it goes on to the evaporators. The sulfur dioxide also bleaches the juice to improve flavor and texture. Without this step an alkaline juice would be produced. The sugar crystals would stick together due to moisture absorption and have an undesirable taste. Again, pH control is essential to efficient operation. The sugar juice is then heated to drive off any residual gases and provide a neutral product.

Further purification sometimes uses carbon beds and ion exchange resins, to remove the last traces of color and impurities. (Conductivity measurement is a key variable in monitoring the operation and regeneration of ion exchange beds.) The purified thin juice then moves on to multi-effect evaporators for concentration, vacuum pans for crystallization, centrifugal separators and dryers.

pH Sensor Requirements

pH sensors must stand up to severe process conditions during the liming and carbonation stages, to provide consistent measurement.

Difficulties

- CaCO3 precipitates on every surface including probes.

- Carbonators operate at 95°C

- Sugar juice temperature compensation curves do not conform to standard temperature correction curves

- Sugar juice contains Sulfur dioxide that reacts with typical reference probes

- Environmental conditions are wet, hot and corrosive

Application Solutions

Analyzer

The Yokogawa FLXA402 has an automatic sensor washing function, self-diagnostics and custom temperature compensation. Besides the cleaning function the sensor washing cycle also provides an online response test, giving an immediate indication of sensor deterioration.

Sensors

In the past mainly single electrodes was used. Installation was done in the bypass together with a chemical cleaning system. To prevent the reference sensor from clogging and poisoning a flowing type reference sensor, like the well- known Bellomatic electrode, was preferred.

As pH- electrode a heavy duty glass electrode with chemical resistances as well designed for high temperatures was used. Today Yokogawa's combined pH- sensors such as SC25, FU20 and FU24 are fulfilling these demands and are used successfully in this application.

If the sensors are cleaned regulatory with diluted acids they will offer good service life. (cleaning frequency depending on the application: carbonation 1st tank or 2nd tank). By using an automatic retractable cleaning system (e.g. EXAtrac) even a direct process installation is possible.

The transmitter stores the calibration data and if the asymmetry potential exceeds 50 mV and the slope drops below 80%, then replacement must be considered.

Industrien

-

Chemical

Chemical plants rely on continuous and batch production processes, each posing different requirements for a control system. A continuous process calls for a robust and stable control system that will not fail and cause the shutdown of a production line, whereas the emphasis with a batch process is on having a control system that allows great flexibility in making adjustments to formulas, procedures, and the like. Both kinds of systems need to be managed in available quality history of product, and to be able to execute non-routine operations. With its extensive product portfolio, experienced systems engineers, and global sales and service network, Yokogawa has a solution for every plant process.

-

Food & Beverage

At Yokogawa, we understand that today’s food and beverage companies face unprecedented challenges in climate change, consumer demand, and increased global competitiveness. Overcoming these challenges will require innovative solutions that focus on key areas of production, asset management, and food safety and quality.

Zugehörige Produkte & Lösungen

-

12 mm pH-Sensor SC25V

Der SC25V ist ein pH-Sensor im 12 mm-Design, der über ein integriertes Temperaturelement und eine Flüssigkeitserde-Elektrode verfügt.

-

Digitaler SENCOM™ SMART-Adapter, SA11

Wiederverwendbarer SMART-Adapter, bei dem nur der Analogsensor am Ende der Lebensdauer entsorgt werden muss. Mit der Plattform SENCOM 4.0 reduziert Yokogawa Kosten und Abfälle und trägt damit zu seinem langfristigen Unternehmensziel einer nachhaltigen Zukunft für alle bei.

-

Mehrkanal-4-Leiter-Analysator FLXA402

Die Analysatoren der FLEXA™-Serie sind modular gestaltete Analysegeräte für kontinuierliche Online-Messungen in industriellen Anlagen. Sie ermöglichen Messungen mit einem oder mehreren Sensoren.

-

pH/ORP-Universalsensor der Serie FU20 und FU24

Die Universalsensoren FU20 und FU24 für pH und ORP (Redox) zeigen, wie Yokogawa das Motto „einfach ist am besten“ auf Sensortechnologie anwendet.

-

Flüssigkeitsanalysatoren

Flüssigkeitsanalysatoren dienen der Überwachung der Prozesschemie und der Wasserqualität und ermöglichen die Optimierung und Regelung der Prozesse.

-

pH- und ORP-Analysatoren

Sensoren und Analysatoren für pH und ORP (Redox) werden zur kontinuierlichen Überwachung von pH- und ORP-Werten im Prozess eingesetzt, z.B. um die Wasser- und Produktqualität sicherzustellen oder um Abflüsse, Batch-Neutralisierung, Zellstoffbestand, Gaswäscher, Kühltürme, chemische Aufbereitung, Wasser- und Abwasserbehandlung und viele andere Anwendungen zu überwachen.