The ability to deliver the full scope of project execution in industrial automation projects is more important than ever.

Challenges for Customers

As global energy demands increase, plants have a mission to achieve high-quality project execution, plant operations, and maintenance.

However, companies are increasingly constrained by personnel issues, budgets, and shrinking timetables. Aside from grassroots construction activity in emerging markets, companies are also faced with the task of executing multiple projects simultaneously in disparate geographic regions.

Our Solutions

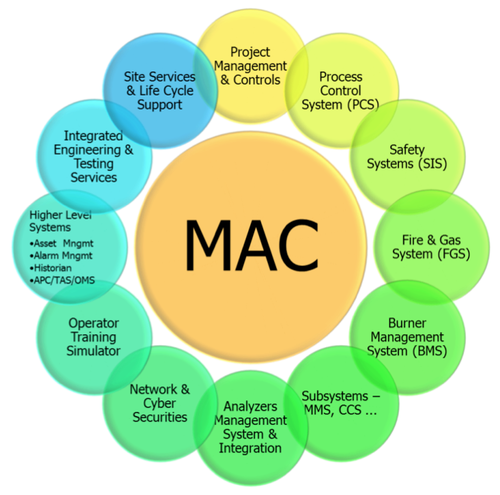

Increasingly, companies depend on Yokogawa to take on the role of main automation contractor, owning responsibility over all automation-related aspects of the project with our Innovative MAC Services (yi-MAC) method of project execution.

Yokogawa provides highly qualified and well-resourced control systems specialists to engineer, supply/procure and manage instrumentation, control systems, safety instrumented systems, and associated interfaces for all project components and facilities.

Customer Benefits

Yokogawa as a MAC assumes responsibility over all automation-related phases of the project.

The Yokogawa MAC team constructs the most suitable project organization and works directly with the end users, EPCs, and third parties. With the MAC approach of dealing with Yokogawa directly, it isn't necessary for customers to manage various automation suppliers.

Instead, customers can derive cost savings, risk mitigation, and shorter delivery times, etc. With our global engineering network and resources, Yokogawa can safely and efficiently execute projects, and then provide optimal operations support over the entire plant lifecycle.

Traditional Approach vs MAC Approach

Compared to a traditional approach, Yokogawa MAC enables drastic costs saving for the overall project.

Many of the world's leading end users, particularly in the process industries, are applying the MAC approach to their entire capital project. The MAC approach can result in project cost savings of up to 30% against a traditional approach. Costs are reduced in nearly all phases of the project, since automation suppliers are encouraged to consolidate industry and application expertise to execute projects in a consistent manner. This means developing practices and procedures that are standard and can be applied across multiple projects to reduce costs.

Details

Companies can recognize significant benefits by partnering with Yokogawa as their main automation contractor:

- Total project management

- Single point of responsibility and single window

- Commitment to the customer on a corporate level

- Entire automation design and engineering

- Automation standardization for multi-projects

- Design of automation standards

- Shortened delivery times

- Minimized unexpected changes due to early MAC involvement

- Minimum customer involvement during project execution

- Global engineering locations and resources

- Global procurement network

- Cost savings and risk mitigation by dealing with Yokogawa directly

Services

- Project Management

- Cost & Schedule Control

- FEED & Detail Engineering

- Procurement Support

- Vendor Package Interfaces

- System Integration & Programming

- Construction Support

- Commissioning Support

- Training

- Operations Support

Deliverables

- Process Control & SCADA Systems

- Process & Emergency Shutdown Systems

- Fire & Gas Detection

- Information Systems

- Communication Systems

- Selected Instrumentation

- Transmitters

- Control Valves

- Level Instruments

- Selected Packages

- Metering Skids

- Instrument Buildings

- Training Simulator

- Historian/MES

- Capital Spare Parts

Resources

- 16,000 FOUNDATION Fieldbus devices

- Main Automation Contractor (MAC)

- DCS anywhere concept integration with site SAP system

- Long term maintenance contract

- Sustainable development

In 2011, Pandora Methanol acquired petrochemical production facilities in Beaumont, Texas that had been mothballed since 2004. These two plants, a 13-year old ammonia plant and a 50-year old methanol plant, had received only marginal maintenance during this extended shutdown and had suffered direct hits from two major hurricanes.

Nederlandse Aardolie Maatschappij (NAM) is the Netherlands' largest natural gas producer. In addition to onshore fields, NAM operates manned platforms and four unmanned monotowers in 19 offshore locations. These connect to a pipeline network that comes ashore at Den Helder.

- As the main automation contractor (MAC) for this plant construction project, Yokogawa Brazil engineered, installed, and commissioned an integrated control and instrumentation solution

- Yokogawa Brazil completed the commissioning of these systems ahead of schedule and the production of green polymer was started just one week later

- Yokogawa receives award for hot cutover of BP Sharjah plant DCS.

- Yokogawa was selected by BP as main automation contractor (MAC) for a project to replace the Sharjah plant's existing legacy DCS with Yokogawa CENTUM VP.

The Mars B Project added the following greenfield infrastructure to boost production at the Mars field and nearby exploration discoveries: the Olympus tension leg platform (TLP), which has 24 well slots and a self-contained drilling rig; the West Boreas/South Deimos subsea system; and an oil and gas export system, which includes the WD-143C shallow-water platform. The Olympus tension leg platform (TLP) started producing on February 4, 2014. The TLP is the second at the Mars field and the sixth of its type for Shell in the Gulf of Mexico.

Continuous Control Solutions ("CCS") has been providing advanced turbo machinery solutions to global markets since 2000 with a steadfast focus on developing advanced control algorithms implemented in the customer's choice of PLC or DCS hardware platform. CCS Turbo Machinery Control Solutions have been implemented on a variety of hardware platforms including Allen Bradley ControlLogix, Honeywell C300, Siemens S7, ABB AC800M and Emerson DeltaV.

Continuous Control Solutions ("CCS") specializes in industrial turbo-machinery control challenges for various types of industries. CCS' turbo-machinery technology and patented control algorithms are hardware platform independent and have been successfully implemented on different hardware platforms since 2004.

Agile Project Execution is YOKOGAWA's methodology to execute all projects in a cost efficient way by removing waste.

With the release of the new CENTUM VP R6, a solution platform that exceeds the capabilities of conventional production control systems, customers can take full advantage of the new features like Network-IO providing decoupling of hardware and software and the new Automation Design Suite.

Over the past decade, companies have been using unconventional drilling technology to extract gas and liquid from the readily available shale formations in North America. As the industry gains experience, the production rates continue to rise based on better use of technology to locate resources and to decrease the time from exploration to production.

yi-MAC stands for YOKOGAWA Innovative Main Automation Contractor:

- Full control of scope and schedule across packages

- Realization of customer expectation

- Single point of responsibility

- Providing fully integrated solutions

Network-IO can help reduce projects by decreasing the amount of time needed to implement the physical part of the process control system. A system with configurable I/O allows flexible "binding," in which the soft- ware configuration of the system can be loaded into the physical system at a late stage in the project.

The ability to deliver a full scope of project execution capabilities is becoming more important than ever for automation suppliers that wish to compete on a global scale. Process automation suppliers have always had some degree of project execution capabilities, but only recently have suppliers and end users begun to realize the true economic impact that precise and comprehensive execution capabilities can have on the success of an automation project and on plant lifecycle costs.

When a project is executed following the main automation contractor (MAC) method, front-end engineering and design (FEED) is conducted before actual delivery phases such as design, implementation, inspection, and shipment, to identify risks in advance and mitigate risks in delivery phases through the standardization of the basic functions and components.

Instrumentation devices and equipment serve for plants as the eyes, ears, nose, tongue, and skin, which are responsible for the five senses, and act as the central nervous system and brain do for human beings. The reliability and availability of such devices and equipment are the most important requirements of customers.

Videos

News

-

Press Release May 12, 2017 Yokogawa Wins Order to Supply Analyzer House for Malaysia's RAPID Project

- Momentum builds for our process analysis systems integration business -

Looking for more information on our people, technology and solutions?

Contact Us