Optimize lot, campaign, recipe, and grade management with KPI visualization, improving QCD

Integrated system will ensure reliability by linking design, operation, and analysis, also mitigating operational planning risks, quality inconsistency, and audit workload.

- Easily execute frequent recipe modifications

- Scheduler resilient to fluctuations in demand

- Inventory management to enhance profitability and product quality

- AI-enabled analysis to identify quality variations

- Ensure cybersecurity readiness

Details

Challenges

The acceleration of manufacturing risks due to diversified end-user requirements

Operational planning risks

- Complex schedules

- Inventory shortages and overstocks

- SOP lacking clarity

- Ineffective safety compliance

Quality inconsistency

- SOP allowing different interpretations

- Inconsistencies in manual data input

Audit complexity

- Time-consuming customer inquiries

- Audits managed through paper or files

- Cybersecurity concern/security concern

Solutions

Three effective measures to mitigate risks in production

Flexible planning

- Visualized schedules with easy plan adjustments

- Inventory visibility & management

- Simplified SOP creation

- Safety assurance through instrumented safety systems

Reliable execution

- Standardized SOP execution to eliminate interpretation gaps

- Automated data collection to reduce human error and input inconsistencies

- Integrated quality management ensuring uniform standards

- Centralized data integration

- AI-enabled analysis to detect deviations early

- Resolution of 4M issues (huMan, Machine, Material, Method)

Trusted Audit & Security

- Reliable records & traceability

- Flexible traceability to meet user requirements

- Robust cybersecurity measures

Benefits

Maximizing customers benefit with consistent quality

Accelerate time-to-market

- Reducing opportunity losses

- Optimized inventory

- Enhanced safety and reduced operational risks

Consistent quality

- Minimized rework and waste to achieve first-pass quality

- Elimination of quality variations via AI analysis

End-user reliability

- Automated electronic records make reducing workload and stress

- Reliable quality assurance

- Prevention of information leakage

-

Lab-Aid

Lab-Aid ist ein Laboratory Information Management System (LIMS) (Laborinformationsmanagementsystem), das Qualitätsmanagementaktivitäten unterstützt. Darüber hinaus standardisiert es Qualitätsmanagementaktivitäten, um Kosten zu senken und den Service Level zu verbessern.

-

Elevate batch production quality with workflow automation

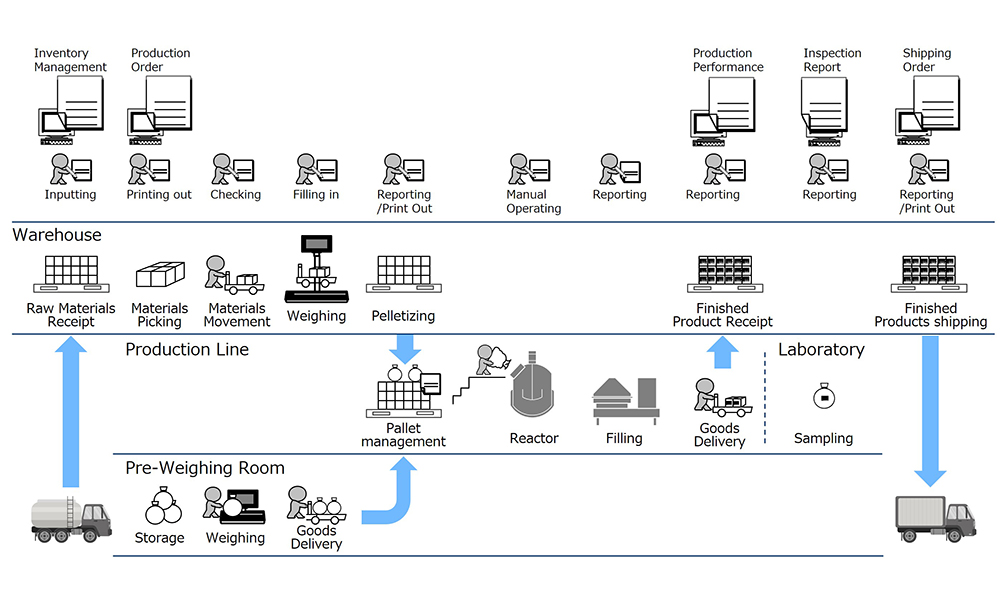

Transform batch process manufacturing with Yokogawa’s automation solution. Seamlessly integrate EBR, WMS, and LIMS for real-time decision-making, enhanced product quality, and streamlined operations

-

CENTUM VP

CENTUM VP verfügt über eine einfache und gemeinsame Architektur, die aus Mensch-Maschine-Schnittstellen, Feldsteuerstationen und einem Steuerungsnetzwerk besteht.

-

Batch Data Historian (Exaquantum/Batch)

Exaquantum/Batch is an intelligent ISA-88 Batch Information System. It provides verified analysis and reporting facilities that collect, store and display current and historical data from batch production, equipment and recipe viewpoints.

Möchten Sie weitere Informationen über unsere Mitarbeiter, Technologien und Lösungen?

Kontakt