A Predictive Maintenance Solution to Prevent Sudden and Critical Failures

Realizing Unstoppable Manufacturing Equipment

With manufacturing sites experiencing labor shortages and aging equipment, there is a growing need for “predictive maintenance.” Predictive maintenance, whereby data is collected from various sensors to predict equipment performance degradation or failure and perform maintenance at the optimal time, is an essential technology for safe and stable operations.

The Multi-Sensing Remote I/O Analog Sensing Unit VZ20X performs reliable sensing to visualize the status of legacy equipment that has not been converted to digital operation. By incorporating IoT and AI, the unit identifies signs of deterioration and facilitates predictive maintenance. As such, it keeps problems with equipment to a minimum and helps ensure improved productivity and efficiency in facility maintenance.

The VZ20X Meets the Needs of the Following Users:

- Those who want to inspect and replace industrial machinery (production equipment) in a timely manner.

- Those who want to add to or improve existing industrial machinery without placing a strain on it.

- Those who want to prevent minor stoppages and major failures in industrial machinery.

>>Download: Predictive Maintenance for Long-Distance Production Lines Seen through Case Studies

Digital transformation (DX) is here, and manufacturing sites are urgently transforming operations using IT to address aging production equipment and labor shortages.

In this document we introduce predictive maintenance in long-distance and complex production lines, with an example of visualization for maintenance of pumps and manifolds on production lines.

>> Download sample program for VZ20X connection

>> Download sample program for VZ20X connection

This is a sample program that collects data by connecting to a PC or PLC. Try it out to experience the convenience offered by the VZ20X.

*The analog sensing unit VZ20X is sold in Asia, Europe, North America, South America, and Africa. However, some areas are excluded.

The Predictive Maintenance That Manufacturing Sites Require

In conventional manufacturing, maintenance consists of “corrective maintenance,” performed after a failure, and “preventative maintenance,” performed periodically. However, these maintenance methods present problems such as labor-intensive maintenance work and the inability to prevent sudden equipment failures. As such, they represent a major burden for manufacturing sites, which are increasingly short on manpower.

This is why “predictive maintenance,” whereby signs of failure are detected and maintenance is performed accordingly, has been attracting attention. With predictive maintenance, maintenance is performed only on equipment that shows signs of failure, thus significantly reducing the man-hours and cost involved in maintenance operations. In addition, downtime due to sudden equipment failures can be minimized, thus improving uptime.

The VZ20X, Enabling Predictive Maintenance

The VZ20X is the world’s smallest class of sensing remote I/O unit, capable of simultaneously measuring various analog sensor signals with high speed, high accuracy, and at high voltages. The measured data is sent via Ethernet to a higher-level system that performs monitoring and constantly assesses the status of the facility. Predictive maintenance is achieved by quickly detecting signs of equipment failure or deterioration, thereby resolving issues of reduced uptime and safety due to equipment stoppages.

About OpreX

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business and stands for excellence in the related technology and solutions. It consists of categories and families under each category. This product belongs to the OpreX Components family that is aligned under the OpreX Measurement category.

Details

Benefits of VZ20X Installation

The VZ20X is equipped with the ideal features for implementing predictive maintenance. This section describes some of the benefits of installing the VZ20X at your manufacturing site.

Converting Signs of Deterioration Into Digital Data Allows Optimal Timing of Replacement and Inspection

The VZ20X collects data from multiple sensors simultaneously at high speed and with high accuracy to visualize signs of equipment deterioration. Combined with Yokogawa Electric’s proprietary AI, equipment anomalies and signs thereof can be analyzed and detected at an early stage. This makes possible CBM (condition-based maintenance), in which maintenance is performed at the optimal timing in accordance with the condition of the equipment. This reduces the man-hours required for inspection and parts replacement, helping to achieve labor savings in maintenance work.

Easy Installation on Existing Equipment to Acquire Diagnostic Data and Make Improvements

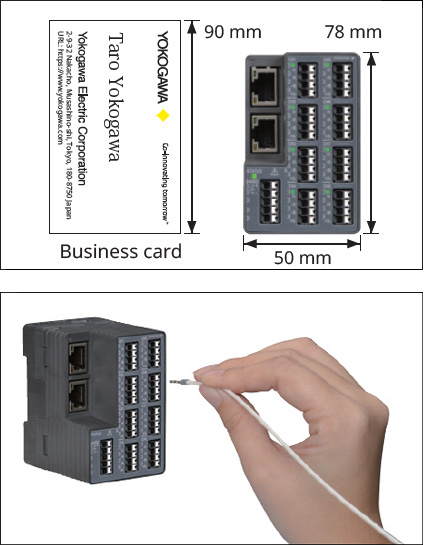

The VZ20X is one of the world’s smallest analog sensing units, shorter and narrower than a business card, and weighing less than 200g. Because it can fit in the gaps between production equipment, it can be easily replaced, minimizing the need for extensions or modifications to existing facilities. It can be applied to evaluating the performance of batteries installed in tight spaces inside a vehicle, or to predictive maintenance of unmanned vehicles.

Furthermore, it employs a push-in connection mechanism that allows installation simply by inserting a ferrule terminal, eliminating the need for special tools. These advantages make it easy to install on any piece of equipment without requiring much space or wiring, allowing predictive maintenance and evaluation of products and components.

High Noise Resistance Helps Ensure Safe Operation

The VZ20X provides stable data measurement thanks to its improved isolation between input channels and noise resistance. Because it can measure highly reliable data even when simultaneously measuring multiple channels or in environments where noise is likely to occur, it is able to accurately analyze the cause of equipment failures. This reduces the number of cases of imprecise maintenance, which in turn reduces the man-hours required for maintenance work.

Also, when using VZ20X in production quality evaluation, safe and reliable testing can be performed because it is less susceptible to the characteristics of products and components and the testing environment.

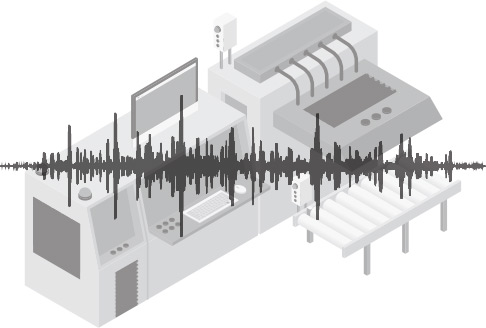

High-Speed and Highly Accurate Sensing Detects Signs of Failures Before They Occur

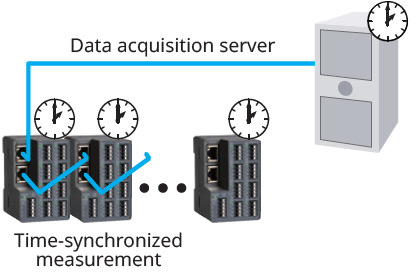

A single VZ20X unit can measure 8 channels of analog inputs at high speed with a sampling cycle of 1 ms. It supports simultaneous measurement by up to 15 units across 120 channels, helping to enable predictive maintenance at manufacturing sites where large amounts of equipment and many sensors are in operation. It is also capable of extremely precise measurement with synchronization accuracy of ±100 µs, measurement accuracy of ±0.05%, temperature measurements accurate to within ±0.16°C, and voltage measurements accurate to ±1mV. In this way, high-speed and highly accurate measurements that do not miss even the slightest changes in the equipment enable the prediction of failures.

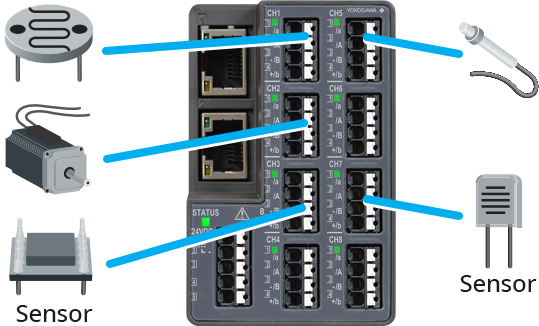

Monitors Equipment Status With Support for All Kinds of Analog Sensors

DC voltage, 4-wire resistor, thermocouple (TC), and 3-wire/4-wire RTD can be measured with a single unit. The use of analog sensors that support these inputs allow a variety of data to be measured, eliminating the need to use numerous data measurement devices for different kinds of sensors.

Accurate Sensing Even Without a Power Outlet

Using the USB Type Detection Disable feature, the VZ20X can be powered by sources other than USB Type-C. Powering the device from a PC’s USB Type-A port eliminates the need for an external 24V DC power supply or power cable, reducing installation and wiring costs. Moreover, by connecting the VZ20X to a commercially available PoE (Power over Ethernet) splitter, it is possible to supply power using an Ethernet cable.

Examples of VZ20X Applications

VZ20X can be used in CBM (condition-based maintenance) at manufacturing and logistics sites.

Manufacturing Plants: Predictive Maintenance of Manufacturing and Logistics Equipment

Recently, manufacturing plants have been making use of automatic guided vehicles and other advanced automation systems to reduce the number of workers on production lines. However, there are still many pieces of analog equipment for which it is difficult to successfully detect signs of deterioration, leading to issues of reduced operating rates due to sudden failures.

The VZ20X is extremely small and lightweight, about the size of a business card, and can be retrofitted to existing analog equipment. Furthermore, when combined with Yokogawa Electric’s data logging software (GA10), real-time OS controller (e-RT3 Plus), and its proprietary AI, highly accurate data collection, monitoring, anomaly detection, and causal analysis can be achieved. Properly timed maintenance reduces the number of man-hours required to troubleshoot problems associated with equipment stoppages, contributing to improved uptime and labor savings.

Specifications

Main Body: Analog Sensing Unit: VZ20X-1N1NDD

| Item | Specification |

|---|---|

| Number of inputs | 8 channels |

| Input types | DC voltage, 4-wire resistor, thermocouple, and 3-wire/4-wire RTD |

| Data acquisition interval | 1 ms (fastest), 8 channels simultaneous measurement |

| Meas. synch. accuracy | Within ±100 μs (between input channels, between units) |

| Measurement accuracy | 0.025% of FS (with DC voltage, and power supply frequency noise removal filter enabled) |

| Withstanding voltage | 3,000 VAC (50 Hz/60 Hz) 1 min. (between analog input channels, analog input-to-internal circuit) |

| Power supply | 24 VDC or USB |

| Operating temperature/humidity | -10–55°C (DIN rail-mounted), -10–50°C (on desktop installation) /5–90% RH |

| Wiring | Push-in terminal, Ferrule terminal |

| Size | Height (H) 78 x width (W) 50 x depth (D) 65 mm |

| Ethernet communication | 2 ports, protocol: Modbus/TCP, GA10 dedicated protocol |

| Installation | DIN rail-mounted, On desktop installation |

| Standards |  |

VZ Configurator

| Item | Description |

|---|---|

| Parameter settings | Input range/scale, Ethernet communication conditions |

| Monitor function | Real time monitoring Self-diagnosis |

| Maintenance | Firmware update Input adjustment |

Resources

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipments do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipments, and data collection can be easily monitored via Ethernet (Modbus/TCP).

VZ20X

Production stoppages caused by sudden malfunctions in production equipment are a serious loss of opportunity.

Equipment inspections to prevent failures are often carried out based on the experience and sense of maintenance personnel, and are fraught with risks.

Customers want to perform maintenance appropriately in accordance with the timing of regular stoppages and the condition of the equipment, not as a rule of thumb for maintenance personnel.

To meet these expectations, the VZ20X can be installed compactly in the gaps of existing production equipment, and by accurately capturing the status changes of each, it contributes to reducing the risk of them.

When maintenance work of production equipment or trouble occurs, customers want to check the situation at the site immediately.

They also want to prepare easily for that (building a measurement system).

In response to these demands, the VZ20X and GA10 make it easy to construct a DATA collection system (on-site confirmation system) and quickly check the status of production equipment.

Customer can cover long-distance area and the VZ20X is very compact to install into small space of any equipment .

Due to revisions and additions to regulations, pumps used in water, sewerage, and drainage systems require flexible modifications and additional measurement points in their performance inspections.

In response to these changes in the environment and circumstances, the compact size of the Multi-Sensing Remote I/O Analog Sensing Unit VZ20X reduces the burden of expanding and reconstructing production and test equipment to fit the current installation environment.

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipments do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipments, and data collection can be easily monitored via Ethernet (Modbus/TCP).

Since performance evaluation tests of inverter drive motors are susceptible to noise, equipment with high noise resistance is required. Also, if the number of measurement points is large, a multi-channel measuring instrument that satisfies the measurement will be costly.

The VZ20X is noise-resistant and safe for accurate DATA collection even on noise-prone measurement targets such as inverters.

It is hard to go back and forth between the office floor and the test floor to check the bearing durability status.

That round trip time is wasteful and a heavy burden on man-hours. If you have more than one test floor, that's even more of a burden.

The VZ20X and GA10 make it possible to build simple monitoring systems. The system also enables remote monitoring of manufacturing and testing sites, contributing to reducing the burden on the site.

DATA of several production equipment in a semiconductor manufacturing factory is currently being checked by field workers, and the checking is in a difficult situation. Therefore, there is a growing demand for centralized monitoring within the factory.

The VZ20X allows installation to take advantage of existing space.

In addition, the GA10 contributes to labor saving in the field by remote monitoring.

When maintenance work of production equipment or trouble occurs, customers want to check the situation at the site immediately.

They also want to prepare easily for that (building a measurement system).

In response to these demands, the VZ20X and GA10 make it easy to construct a DATA collection system (on-site confirmation system) and quickly check the status of production equipment.

In the painting process of automobile parts, failure or corrosion of electrodes can lead to quality degradation.

In addition, the current lack of electrode condition monitoring has resulted in the replacement of electrodes in a short period of time, a problem that is extremely costly.

To address these issues, we monitor the deterioration of production facilities and contribute to the realization of maintenance tailored to the conditions of the equipment.

Customers want to monitor the amount of electricity consumed by each production equipment in order to conserve energy in the factory, but it is not easy to install a measurement system in existing equipment, even from the installation and wiring conditions.

The VZ20X's compact size allows it to be installed for existing conditions. Accurate sensing also contributes to the visualization of power usage at production equipment.

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipments do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipments, and data collection can be easily monitored via Ethernet (Modbus/TCP).

The PLC in the existing injection molding machine does not have a recording function, but you want to add a function to record the production DATA and equipment condition DATA. Customers also want to easily realize these functions.

In response to these requirements, the VZ20X performs DATA collection of PLC and analog sensors, and the GA10 provides on-site monitoring and recording to support safer operations.

In recent years, customers of processing equipment used in food and pharmaceutical manufacturing have increasingly requested visualization of equipment conditions.

This is because we do not know the current state of our production facilities, and maintenance depends on individual experience and intuition.

By accurately collecting DATA with VZ20X and visualizing the status of equipment, it is possible to understand the current status and perform appropriate maintenance according to the condition of the equipment.

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipments do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipments, and data collection can be easily monitored via Ethernet (Modbus/TCP).

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipment do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipment, and data collection can be easily monitored via Ethernet (Modbus/TCP).

the VZ20X installed near sensors such as temperature, humidity, and vibration, and enables automatic collection of data via the factory LAN. The data collection, monitoring and management can be automatically and regularly monitored with the data logging software GA10. As a result, it contributes to reducing the workload of workers.

Downloads

Brochures

- VZ20X Analog Sensing Unit (5.1 MB)

Instruction Manuals

General Specifications

- Model VZ20X Analog Sensing Unit (918 KB)

Software

Technical Information

Drawings

- Model VZ20X Analog Sensing Unit (271 KB)

News

-

Press Release | Solutions & Products Aug 31, 2021 Yokogawa Releases OpreX Multi-Sensing Remote I/O VZ20X Analog Sensing Unit

- World-class compact design and high performance for production maintenance and the development of EV batteries and other components -

Looking for more information on our people, technology and solutions?

Contact Us