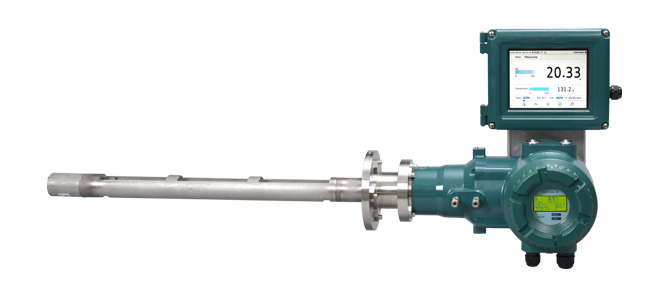

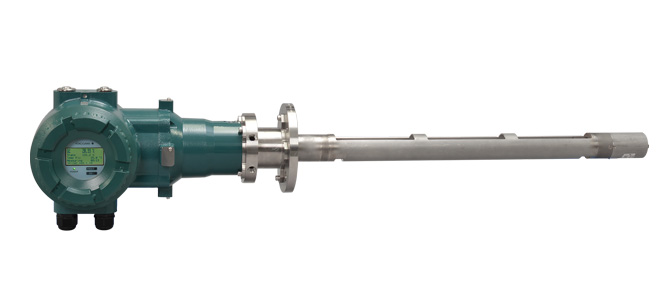

Yokogawa’s new TDLS8200 continues to house all of the industry’s leading features from the TDLS8000, but now only requiring a single-flange installation. An in-situ measurement with a probe still removes the requirement for sample extraction and conditioning and can be used in variety of aggressive process conditions.

The 0.5 meter measurement area of the probe provides some averaging improvement compared with traditional point-sensor technologies, and has flexible positioning of that measurement area with different insertion lengths being offered.

- Measuring with a catalytic sensor on a COe meter poses challenges for durability and data acquisition -

The TDLS8200 is equipped with two systems of lasers that can measure O2 and CO or CH4 in a single unit to overcome such challenges.

You can replace existing sampling devices with either of these.

Built upon Yokogawa’s second generation of TDLS analyzers, the platform still retains its improved reliability, ease of installation, and reduced maintenance requirements, but now does so with lower total-installed cost for O2, CO, CO or CH4, NH3, HCl measurements.

Features and Benefits

Reduced Installation and Maintenance Costs

- Single-flange installation eliminates the difficulties associated with aligning cross-duct solutions

- Measure in locations where cross-duct TDLS technology was not feasible due to obstructions or accessibility issues

- Easy installation with no sample system

- On-board diagnostics with 50 days of data and spectral storage ensure that minor issues can be identified before they become more serious problems

- Fully field repairable

- Compliant with safety level SIL2 for safe operation

- Explosionproof/flameproof for installation in CID1/Z1 or CID2/Z2 (when conbined with YH8000 Z2) areas

- No consumables are used which reduces equipment and time-related costs

- No re-calibration is required

- HART and Modbus TCP come standard to maximize remote diagnostics and configuration capabilities with a single cable run for each

- Manual, semi-automatic, or automatic validations can be performed to regularly test analyzer performance while on process

High Speed Accurate Measurement

- 2 second measurement update with as little as 1 second optional

- TruePeak technology keeps an accurate measurement, even when the process gas changes composition, temperature, pressure, or dust loading

- An in-situ probe eliminates sample lag introduced by comparable extractive technologies

Seamless User Interface

- Intuitive 7.5” touch-screen HMI configurable for 10 different languages

( Japanese, English, German, French, Spanish, Portuguese, Russian, Hungarian, Korean and Chinese ) - Intuitive operability

- Equipped with trend function, improved display function

- CID2/Z2 area rating on the HMI allows for local placement of the primary user interface in the majority of installation areas

- Installation of our free PC-HMI software duplicates the same user interface as the YH8000 HMI for more budget sensitive applications

TDLS8200 Probe type Tunable Diode Laser Spectrometer – Flowcell type

For applications where the TDLS8000, TDLS8200 could not be installed or inserted due to process size, etc., a sampling system can be constructed by replacing the probe part of the TDLS8200 with a flow cell part . Please contact Yokogawa.

TDLS8200 Probe type Tunable Diode Laser Spectrometer - Reflective type

Even in applications where the pipe diameter is small (0.5 m or less), a Reflective type TDLS8200 doubles the optical path length, making measurement possible.

System configuration

Standard system configuration

- Connectable with FieldMate or other DTM/DD compatible device management software using HART communication

- Mini Display

System configuration with remote YH8000 HMI

- Connect up to 4 analyzers simultaneously

- Can be used with the cross-duct TDLS8000 and/or the TDLS8200 probe

Measured gas

- O2+CO or CH4

- Other near-infrared absorbing measurement gases may be available upon request

About OpreX

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business and stands for excellence in the related technology and solutions. It consists of categories and families under each category. This product belongs to the OpreX Analyzers family that is aligned under the OpreX Measurement category.

Details

Structural Features

Easy installation reduces installation cost

Access on one side only

- No longer a maintenance scaffold needed on both sides

- No crossover wiring required for light launcher/ detector dedicated cable

Replace of extractive gas sampling analyzer

- Just replace gas sampling probe

- No expendable items such as filter, pump diaphragm

Long-term stable measurement

- Optical, hydrodynamics, thermal and vibration designed Probe to stabilize laser optical axis and optical path length for a long time

No light adjustment is required

- Since there is no light launcher side / light detector side, optical alignment is unnecessary

Robust and stable measurement realized

Resistant to vibration

- Even during vibration, various measurements enable laser light reception and achieve stable measurement

Features

Spectrum area method realizing high accuracy

In the conventional wavelength modulation method (2f method), the shape of the absorption peak and the height of the peak are affected by the interference gas. Yokogawa's proprietary spectral area method is virtually unaffected by the interference of other gases and can be measured with high accuracy by temperature and pressure correction.

High Reliability

Reference Cell

Internal reference cell in the laser module ensures peak locking during trace measurement.

Intuitive operability HMI YH8000

- Touch screen 7.5 inch color LCD on HMI

- Intuitive operability

- 10 languages display correspondence

( Japanese, English, German, French, Spanish, Portuguese, Russian, Hungarian, Korean and Chinese ) - Equipped with trend function, improved display function

- Up to 4 analyzers can be connected simultaneously

*For details of the HMI unit YH 8000, refer to the tab of "YH8000 HMI unit".

The simple and robust TDLS8200 assures the reliable and less maintenance operation of the analysis.

Fired Heater Combustion Safety and Lifecycle Management

Yokogawa TDLS8200 simultaneously measures multi-gas like O2, CO, and CH4, providing, FAST, quick and reliable information to achieve:

- Combustion Efficiency Improvement

- Safety Improvement

- Longer Life time of the coils and coil hangers

- Higher throughput thru optimizing heating

Limiting O2 Concentration for safety and process monitoring & control

Yokogawa TDLS8200 O2 analyzer achieves;

- No Sampling system required so less maintenance

- Fast Response Analysis

- No Interference Analysis (TruePeak measurement technology)

- Internal reference cell for peak locking during trace measurement

Major Industries

Oil & gas, petrochemicals, chemicals, electric power, iron and steel, and ceramics

Applications

Heating furnace and boiler combustion control and safety monitoring

TDLS8200 STANDARD SPECIFICATIONS

| Measurement object | O2+CO, O2+CO or CH4, O2, CO, CO or CH4, NH3, HCl | ||

|---|---|---|---|

| Measurement system | Tunable diode laser spectroscopy | ||

| Measured component | Min. range | Max. range | |

| O2 | 0-1% | 0-25% | |

| CO (ppm) | 0-200 ppm | 0-10,000 ppm | |

| CO or CH4 | CO | 0-200 ppm | 0-10,000 ppm |

| CH4 | 0-5% | ||

| NH3 | 0-30 ppm | 0-5,000 ppm | |

| HCl | 0-50 ppm | 0-5,000 ppm | |

| Probe length | 0.7 m, 1.0 m, 1.5 m, 2.0 m | ||

| Optical path length | 1m | ||

| Analog output | 5 points, 4 to 20 mA DC Output types: Gas concentration, Transmission, Process gas temperature, Process gas pressure |

||

| Digital communication | HART, Ethernet | ||

| Digital output | 2 points, contact rating 24 V DC, 1 A DO : Function: Activate during Warning / Calibration /Validation / Warm up / Maintenance conditions Fault: Function: Activate during Fault condition or when the system power is off |

||

| Power supply | 24 V DC ±10% | ||

| Protection degree | IP66/NEMA 4X | ||

| Process gas condition | Process gas temperature: Max 850°C Process gas pressure: 90 to 500 kPa abs. Process gas flow velocity: 1 to 30 m/sec |

||

| Installation condition | Ambient operating temperature: -20 to +55°C Storage temperature: -30 to +70°C Humidity: 0 to 95%RH at 40°C (non-condensing) |

||

| Functional safety | IEC61508 SIL2(SC3) | ||

| Hazardous area classifications | Division1, Zone1: Explosionproof FM (US, Canada), IECEx, ATEX/UKEX, NEPSI, Korea, Japan |

||

PERFORMANCE

| Measured component | Repeatability | Linearity | |

|---|---|---|---|

| O2 | ±1% reading or ±0.01% O2, whichever is greater | ±1% F.S. | |

| CO (ppm) | ±2% reading or ±1 ppm CO, whichever is greater | ±1% F.S. | |

| CO or CH4 | CO | ±2% reading or ±1 ppm CO, whichever is greater | ±2% F.S. |

| CH4 | ±4% reading or ±0.02% CH4, whichever is greater | ±4% F.S. | |

| NH3 | ±2% reading or ±1 ppm NH3, whichever is greater | ±2% F.S. | |

| HCl | ±1% reading or ±2.5 ppm HCl, whichever is greater | ±2% F.S. | |

Measurement conditions: 25°C, 0.1 MPa abs., optical path length 1 m

Related products and Maintenance parts

[Related products]

Calibration cell

[Maintenance parts]

O-ring

YH8000 HMI Unit

YH8000 is an HMI dedicated to wavelength tunable semiconductor laser gas analyzer TDLS8000/TDLS8200

- Equipped with easy-to-use touchscreen 7.5 inch color LCD

- Maintenance information display, alarm status and record display, and all parameters of TDLS8000/TDLS8200 are set

- YH8000 can be attached directly to the TDLS8000/TDLS8200 or installed at a remote place

- By using Ethernet connection and hub, up to 4 YH8000 can be connected to TDLS8000/TDLS8200

- Multilingual: corresponding to 10 languages of English, German, French, Spanish, Portuguese, Russian, Hungarian, Korean, Chinese and Japanese

Specification

| Display | Touchscreen 7.5 inch TFT color LCD panel, 640 x 480 (VGA) |

|---|---|

| Communication | Ethernet: RJ-45 connector, Communication speed; 100 Mbps |

| Protection degree of enclosure | IP65, NEMA Type 4X |

| Weight | Approx. 4 kg |

| Mounting | Analyzer mount (Front, left-side, right-side) with tilt function, Pipe mount, or Panel mount (Stainless steel) |

| Cable Entries | 1/2NPT or M20x1.5 mm, two holes |

| Installation conditions | Ambient operating temperature: -20 to 55ºC Storage temperature: -30 to 70ºC Humidity: 10 to 90%RH at 40ºC (Non-condensing) |

| Power Supply | 24 V DC ±10% |

| Hazardous area classifications | Division 2, Zone2: Non-Incendive/Type n; FM (US, Canada), ATEX, IECEx, Japan, Korea, NEPSI, EAC, INMETRO |

*For details, please refer to the specification sheet (GS).

Kaynaklar

Storage tanks are used in a variety of industries ranging from holding crude oil to holding feedstock for vinyl chloride monomer (VCM).

O2 measurement is used to safely recover flue gas containing a high concentration of CO from a converter furnace. With conventional paramagnetic oxygen analyzers, O2 concentrations are obtained through a sampling system to recovery flue gas. Therefore, there are problems with the maintenance and running costs of the sampling system, and time delays in measurement.

İndirilenler

Broşürler

Kullanım kılavuzları (IM)

Genel Özellikler (GS)

VİDEOLAR

The TDLS8200 Probe Type is the newest addition to Yokogawa’s Tunable Diode Laser Spectrometer product lineup. Now with the ability to measure O2, CO, and CH4 with a single device and from a single installation point. The developers talk about it.

Haberler

-

Basın Bülteni Tem 22, 2022 Yokogawa Adds Explosion-Proof Version of TDLS8200 Probe Type Tunable Diode Laser Spectrometer to OpreX Analyzer Lineup

Simultaneous measurement of oxygen carbon monoxide or methane concentrations for optimum combustion control in heating furnaces

İnsanlarımız, teknolojimiz ve çözümlerimiz hakkında daha fazla bilgi mi arıyorsunuz?

Bizimle İletişime Geçin