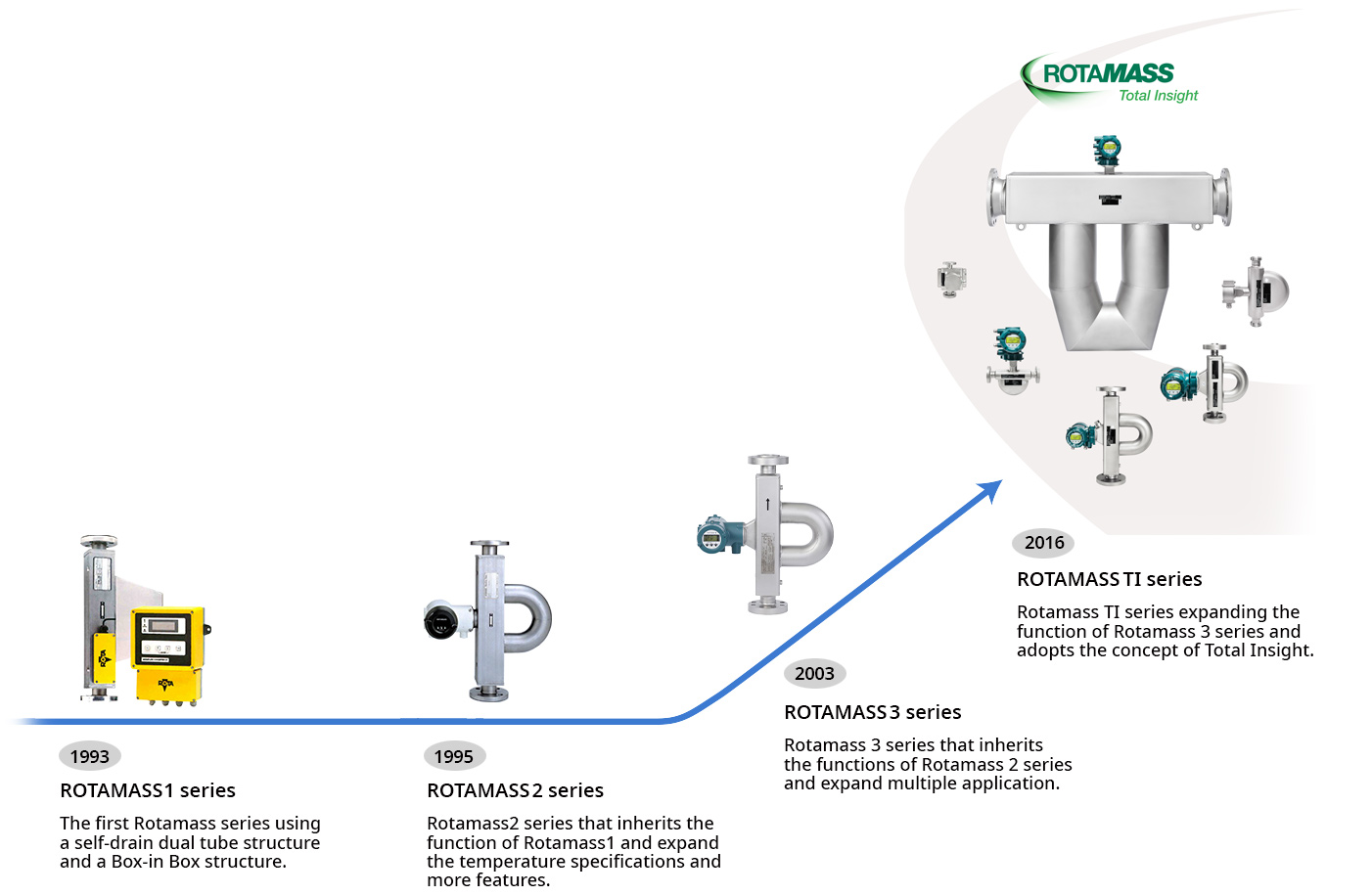

History of Yokogawa’s Coriolis Mass Flow and Density Meters

Yokogawa's Coriolis Mass Flow and Density Meters was sold worldwide in 1993 as ROTAMASS.

The first ROTAMASS was a product that improved noise resistance by adopting a self-drain structure that reduces fluid accumulation, and a Box-in-Box structure that greatly reduces piping noise and flow noise.

In the last decade, the use of Coriolis Mass Flow and Density Meters has been changing from general purpose to supporting your needs in specific applications.

While the technological complexity increased, the demand for simple operation and handling is also a rising requirement.

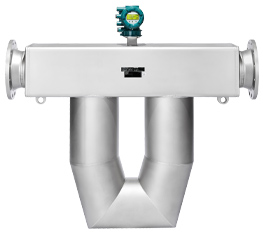

Yokogawa answers these needs by offering six dedicated product lines with two specialized transmitters allowing the highest flexibility -the ROTAMASS Total Insight.

Product Introduction

Rotamass TI can provide very high accuracy for measuring liquids and gases under process conditions.

From the direct mass flow, density, temperature measurements, with Rotamass TI you can calculate:

- Volume flow at operating or reference conditions

- Density at reference conditions

- Concentration measurements of mixable or unmixable fluids

With additional measurement input Rotamass TI can calculate fluid viscosity for Newtonian liquids or energy-heating value for gas measurement.

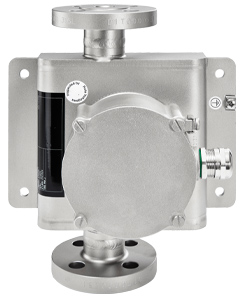

| ROTAMASS Nano |

ROTAMASS Prime |

ROTAMASS Hygienic |

ROTAMASS Supreme |

ROTAMASS Intense | ROTMASS Giga |

||

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

||

| Main Application | For low flow Applications | Versatility with superior turndown and low pressure loss | For food & beverage, biotechnology and pharmaceutical utility applications | Superior performance under demanding conditions | For high pressure applications | Flexible installation for high flow applications | |

| Process temperature | -50 to +260 °C | -70 to +200 °C | -70 to +140 °C | -196 to +350 °C | -70 to +150 °C | -70 to +350 °C | |

| Process pressure up to | 285 bar or 460 bar *1 |

100 bar | 40 bar | 100 bar or 250 bar *1 |

260 bar or 360 bar *1 |

100 bar or 180 bar *1 |

|

| Accuracy | Mass flow for liquids up to | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % |

| Mass flow for gas up to | ±0.35 % | ±0.35 % | ±0.35 % | ±0.35 % | ±0.35 % | ±0.35 % | |

| Density for liquids up to | ±0.5 g/l | ±0.5 g/l | ±0.5 g/l | ±0.5 g/l | ±0.5 g/l | ±1.0 g/l | |

Lineup

-

ROTAMASS Total Insight

It is the most technologically advanced mass flowmeter yet. By combining the superior design of the application specific flow sensor and transmitters with the Total Insight philosophy and functionality, the flexibility of the Rotamass to adapt to changing requirements guarantees performance throughout the lifecycle of the process measurement.

Resources

Necessary oil is a family owned oil re-processor with a presence in the states of Tennessee, Virginia, North Carolina, South Carolina, West Virginia, Kentucky, Indiana, Ohio, and Pennsylvania. A fleet of trucks pick up used oil and discarded coolant from oil change shops and industrial users.

Looking for more information on our people, technology and solutions?

Contact Us