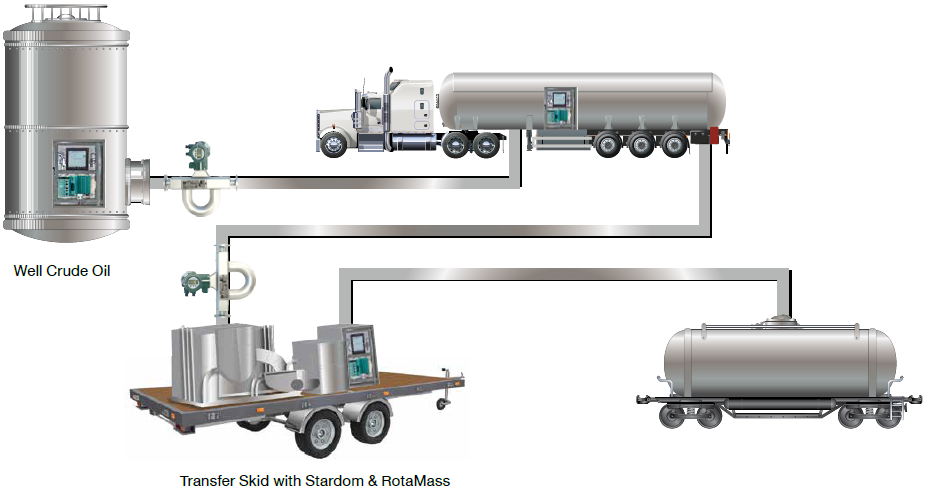

With the rapid advance in oil and gas well drilling over the past few years, pipelines have not kept pace with new drilling sites. Many wells rely on truck and railcar transport to get the oil to refineries and distribution centers. Yokogawa transloading and custody transfer solution packages a 4σ reliability net oil computer with a standard panel containing all the components needed to bring in flow, temperature, pressure, valve, and permissive IO to create a net oil metering solution for trucks, tanks, and railcars.

TRULS is ideal when low power, high reliability, and shortened delivery times are required since the package is pre-configured to handle data mapping to common instrumentation for one coriolis meter and one water cut meter for two phase (oil:water) correction. TRULS complies with API MPMS and ERCB Directive 017 standards and the panel contains pass through ports for easier valve proving.

The standard package (Model #M1290GX) saves on engineering by:

- Incorporating your logo on the screens is part of the standard offering.

- Pre-configuration of standard IO

- Pre-configuration of three common coriolis meters with pre-mapped Modbus addresses; just select the transport media (modbuse ethernet vs. modbus serial) and the device model

- Pre-configuration of a water cut meter with Modbus mapping

- Log file, Truck and railcar database access and configuration via FTP and through memory card access.

- Secure access option for the Operator and Truck driver

- High capacity to meet regulatory and troubleshooting needs - includes 1 year of data logging storage captured at ½-second intervals during each metering transaction for up to –

- 12,000 truck logs

- 12,000 railcar or tank logs

Details

Yokogawa's truck and railcar transloading solution reduces delivery time to 6 weeks or better and delivers a pre-configured package where parameters can be easily re-configured instead of requiring full engineering and programming at the site. Yokogawa uses heavy duty contactors and components to enhance reliability. The solution allows for the use of a calculated water cut based on coriolis meter readings. The net oil computation can also be augmented with a water cut meter where the customer can set the range for when the net oil calculation uses the meter reading instead of the calculated water cut value. Additionally, Yokogawa's net oil calculation allows for a selectable setting of brine algorithms to be used that covers salinity from 0% up to 16% (with ongoing testing for up to 20%).

Yokogawa's liquid net oil calculation provides high accuracy. It matches the API MPMS standard test cases to eight decimal places or better and it fully meets the AGA gas calculation standard. Yokogawa's RotaMass reading accuacy is +/- 0.5% for gas and +/-0.1% for liquids (see General specification 01R4B04-00E-E for more details).

Yokogawa's truck and railcar transloading solution complies with regulatory standards and supports display of data, logging, and optionally Printing batch transfers as well as e-ticketing using configurable determination of Net Oil and water cut based on:

- Configurable ranges for using the water cut meter reading and calculated water cut for use in the Net Oil computation.

Save time on engineering effort, deployment, and maintenance:

- High reliability (4σ FCN-RTU flow computer), heavy duty relay design, industrial HMI & Yokogawa's famed robustness

- Pre-configured IO, screens, and control/flow application

- Pre-configured Truck and Railcar database

- Selectable communication methods for pre-configured/pre-mapped coriolis and water cut meters

- Large 12" color touchscreen display for easy viewing and manipulation

Expandable to meet your future needs –

- Secure wirelessNetwork solutionNetwork storage 1000+ years logging

- Third party IO instrumentation, HART, Foundation Fieldbus, Profibus, Serial

- Communication protocols: OPC, Modbus, FTP

- Low power consumption by net oil computer (as low as 1.6W, typically 2W used for transloading solutions)

Maintain Secure site with:

- Secure Operator and Truck Driver application access

- Safety permissives (grounding and bonding) and alerts to mitigate fires and environmental releases.

Pre-configured to use coriolis and water cut meters:

- Yokogawa Rotamass

- Endress+Hauser Proline Promass 83

- Micro Motion CMF300/400 meter

- Delta C Technologies DC-3510F water cut meter

Flow Computer – custody transfer approved

- Stardom FCN-RTU (see GS 34P02Q13-01E for detailed spec)

Environmental rating:

- Class I Div II, Zone 2

- -40°C to 70°C

Power Supply:

- 10-30 VDC

IO

- AI: 13 points

- Inlet pressure

- Meter pressure

- Air eliminator dP

- Outlet pressure

- Outlet pressure ramp

- Meter temperature AI_7 – AI_12: Spare

- AI_13: Battery Monitoring

- AO: 2 points

- Spare

- Spare

- DI : 16 points

- Main Valve - Open

- Valve Positioned to Tank/Railcar (optional, if diverter valve is used)

- Valve Positioned to Slop tank (optional, if diverter valve is used)

- Main Valve – Closed

- Truck Ground Fault / permissive

- Railcar Ground Fault / permissive

- DI_6: Spare

- Railcar / Tank high level Alarm

- DI_9 – DI_16: Spare

- DO : 8 points

- Main Valve – Open/Close Command

- DO_2: Spare

- Load Alarm High – Red Light

- Load Alarm Warning – Amber Light

- Load Alarm Horn

- DO_6 – DO_8: Spare

- Pulse(0-10KHz) : 2 points (spare)

- Pass Through proving connections

Proving pulse that is pass-through to the flow meter for convenient access by the proving contractor.- Communication port configuration:

- 5-Ethernet ports (100/10Mbps)

- 1-touch screen panel

- 1-electronic flow meter

- 6-Serial ports

- 1 used for coriolis meter

- 1 used for water cut meter

- 1 used for printer (or left spare)

- 3 spare

- 1-USB port used for file transfers

Options:

- Remove thermal printer

- Deliver with 3TB NAS drive

- Deliver with RTD

- Deliver with coriolis

a. Standard RotaMass- Deliver wtih water cut meter

- Deliver with grounding/bonding solution

- Deliver with complete skid

By default TRULS supports net oil computing and metering of Crude Oil, Refined Product, Lubricating Oils, and fluids that described as being within the API MPMS 11.1 scope. The density, pressure, temperature, and fluid ranges are as follows:

| OIL | ||||

|---|---|---|---|---|

| Crude | Refined Products | Lubricating | ||

| Density | kg/m³ @60°F | 610.6 to 1163.5 | 800.9 to 1163.5 | |

| API Gravity @ 60°F | 100.0 to -10.0 | 45 to -10.0 | ||

| kg/m³ @15°C | 611.16 to 1163.79 | 611.16 to 1163.86 | 801.25 to 1163.85 | |

| Temperature | °F | -58.0 to 302.0 | ||

| °C | -50.0 to 150.0 | |||

| P | Pressure (psig) | 0 to 1500 | ||

| α | Alpha60 per °F | 230.0E-6 to 930.0E-6 | ||

| Alpha60 per °C | 414.0E-6 to 1674.0E-6 | |||

Refined Products include –

Gasolines:

Motor gasoline and unfinished gasoline blending stock with a base density range between approximately 50 °API and 85 °API. This group includes substances with the commercial identification of:

|

|

|

Jet Fuels:

Jet fuels, kerosene, and Stoddard solvents with a base density range between approximately 37 °API and 50 °API. This group includes substances with the commercial identification of:

|

|

|

Fuel Oils:

Diesel oils, heating oils and fuel oils with a base density range between approximately -10 °API and 37 °API. This group includes substances with the commercial identification of:

|

|

|

Lubricating Oils –

Lubricating oil is considered to conform to the commodity group Generalized Lubricating Oils if it is a base stock derived from crude oil fractions by distillation or asphalt precipitation. For the purpose of API MPMS 11.1 and TRULS, lubricating oils have initial boiling points greater than 700°F (370°C) and densities in the range between approximately -10 to 45°API.

Natural and Drip Gasolines

Natural and drip gasolines are paraffinic substances and are not actually refined products. Drip gasoline is the paraffinic condensate from gas well production. Drip gasoline is a mixture of natural gas liquids, primarily butanes, pentanes, hexanes, and heptanes. Aromatic natural gasoline should be considered part of the Generalized Refined Products commodity group.

TRULS supports all of these drip and aromatic natural gasoline substances that should be considered part of the Generalized Crude Oil commodity group provided their density lies in the appropriate range.

Reformulated Fuels

API has investigated volume correction factors for reformulated fuels. Included in this study were gasoline

feedstocks containing any one of the following oxygenates: MTBE, ETBE, DIPE, and TAME. The addition of minor proportions of ethers to gasolines, up to 2.7 wt% oxygen, such as permitted in many national fuel

specifications, does not significantly change the correction factors from the Generalized Refined Products table.

The Special Applications procedure, which requires laboratory testing of a representative sample, was also found satisfactory for all of the gasolines, oxygenates, and mixtures studied.

MTBE

Methyl tertiary butyl ether (MTBE) is best represented by the Special Applications procedure with a 60°F thermal expansion factor (α60 ) of 789.0×10-6 °F-1.

JP-4

API MPMS 11.1 guidelines recommend:

- In the general case, represent JP-4 as a Generalized Crude Oil.

- In cases where the buyer and seller agree that a greater degree of precision is desirable, determine the coefficient of thermal expansion of the various blends and use the special application tables. The above recommendations apply only to JP-4 which is a blend. Other jet fuels such as JP-2 and JP-8 or materials that have densities at 60°F of 787.5 kg/m³ or greater are well represented as a Generalized Refined Product.

Pure Compounds

Pure paraffinic compounds (C5+) are well represented as Generalized Crude Oils within the range of the correlations. Non-paraffinic pure compounds (C5+) are not well represented as either Generalized Crude Oils or Generalized Refined Products; however, thermal expansion factors can be determined and these pure compounds can be treated as a Special Application via configuration of the API MPMS 11.1 library used by TRULS. It is recognized that there are some pure components whose densities put them in the range of this Standard and the standard(s) for light hydrocarbons. The two standards give results that are of comparable accuracy but are slightly different. It is up to the contracting parties to decide which is more appropriate to use.

Gasohol

Gasohol is a mixture of gasoline and 10 vol% ethanol. Based on data (available at API) obtained at the University of Missouri – Rolla, gasohol is best represented as a special application with a 60°F thermal expansion factor (α60 ) of 714.34×10-6 °F-1.

Resources

Recently, several ARC Advisory Group analysts and management team members had a chance to sit down with the new Yokogawa President and COO, Mr. Takashi Nishijima, and several other top Yokogawa executives to discuss the company's burgeoning presence in the worldwide upstream and midstream oil & gas industry.

Looking for more information on our people, technology and solutions?

Contact Us