Real-Time Optimization & Process Digital Twin Solution for LNG Plant

Liquefied natural gas plants worldwide rely on proven and highly efficient technologies developed by established licensors. These licensor technologies have undergone continuous advancements and have reached a high level of maturity, making further optimization within LNG process plants increasingly challenging. While licensors keep working to refine their LNG process technologies with the aim of enhancing efficiency and reliability, the focus with plant operations teams is on maximizing the utilization of a plant’s design capacity across a wide range of operating conditions. Achieving additional performance improvements requires advanced optimization strategies that go beyond traditional process enhancements, leveraging real-time data analytics, process digital twins, and dynamic optimization techniques.

With these aims in mind, teams from Oman LNG (OLNG) and Yokogawa collaborated to identify pathways for increasing LNG production within existing plant design limitations. By making use of Yokogawa’s advanced digital solutions, they further optimized LNG production without impacting operational stability or efficiency. This success story underscores the impact that real-time closed-loop optimization, grounded in fundamental principles, can have in enhancing LNG plant performance. It exemplifies how digital strategies can facilitate ongoing improvements in efficiency, reliability, and production capacity.

LNG Process Plant Brief

LNG production starts with the purification of natural gas, utilizing amine absorption and dehydration processes to remove impurities like CO2 and H2S. The purified gas is then liquefied by using C3 and mixed refrigerant to cool it to -162°C, thereby reducing its volume by 600 times. The LNG is stored in cryogenic tanks and transported via specialized LNG carriers. At a regasification terminal, the LNG is warmed and converted back to gas for pipeline distribution. Advanced control systems and safety protocols ensure safe and efficient operations throughout the LNG supply chain.

At the plant operated by Oman LNG, Yokogawa and OLNG teams targeted its liquefaction section for the implementation of a closed-loop real-time optimization solution that makes use of a process digital twin. The liquefaction section in the LNG plant is a highly energy-intensive unit, with the main cryogenic heat exchanger (MCHE) utilizing C3MR technology for the cryogenic cooling of natural gas. Mixed refrigerant (MR) plays a crucial role in liquefying the natural gas and has a major impact on operational efficiency. By deploying a closed-loop optimization solution within the MCHE section, the teams have been able to optimize plant capacity without impacting operational stability. This effectively mitigates fluctuations in plant performance that are often caused by unavoidable variables inherent in plant operations.

Operational Challenges at LNG Plant

Maintaining stability and optimizing LNG production in this LNG plant is always challenging for its operators, as a variety of external factors can significantly affect plant performance and production capacity.

- In the Middle East, significant day-to-night and seasonal fluctuations in ambient temperature and the temperature of sea cooling water can impact the efficiency of compressor drivers and exchangers and the performance of the cooling circuit, including the MCHE. In the summer heat there is less power available for refrigerant compressors; this requires constant adjustments to maintain optimal performance and stable plant operation.

- Additionally, variations in the feed gas rate and composition require operators to constantly adjust operating parameters to maintain efficient unit performance.

- A critical challenge lies in maintaining the optimal ratio with the light mixed refrigerant (LMR) and heavy mixed refrigerant (HMR) streams to ensure effective operation of the MCHE warm and cold bundles. While licensors provide general guidelines, fluctuations in feed gas rate and composition necessitate operator expertise to ensure that the HMR/LMR flow ratio stays optimal. This requires precise adjustments to their flow rates, particularly in response to varying feed gas conditions and changing conditions with the MR and propane refrigeration (PR) circuits.

Yokogawa RT-OP Enhances Existing APC Capability in LNG Plant

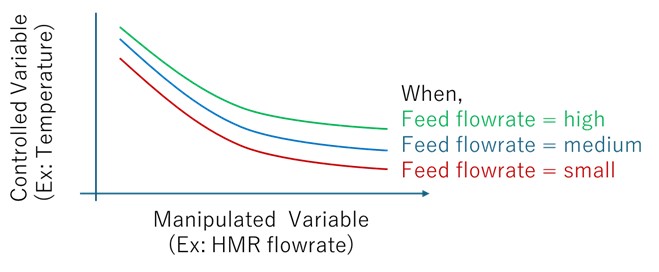

At Oman LNG’s plant, the advanced process control (APC) system is already functioning effectively as a supervisory controller, regulating the underlying control loops to minimize fluctuations in plant operations under all possible conditions. The APC modeling approach indicates that, in the liquefaction section, the LNG rundown temperature and the MCHE warm bundle temperature exhibit a nonlinear relationship with the HMR and LMR flow rates. When the MR flow rate changes—typically influenced by the natural gas feed flow rate—the relationship between LNG rundown temperature, MCHE warm bundle temperature, and the MR flow rates (HMR and LMR) follows different gain models.

Fig-01: Variable nonlinearity based on MR flow regime

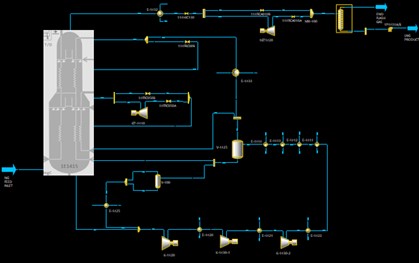

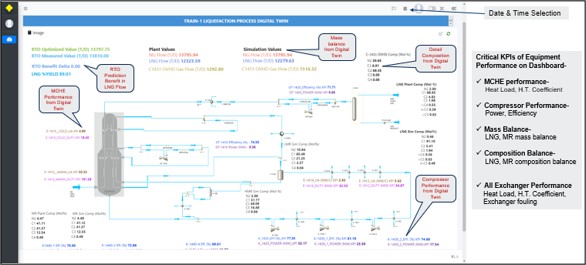

Here, Yokogawa's Dynamic Real Time Optimizer (RT-OP) system plays a crucial role in further optimizing the LNG plant’s operations. RT-OP utilizes a first principles-based high-fidelity model (fig-02) that acts as a process digital twin (PDT) of the plant. This PDT continuously reflects the plant's current operating conditions and dynamically updates the gain matrix. Typically, the gain matrix in the plant is updated every two hours, ensuring that the PDT captures all possible plant conditions and generates gain matrix dynamics. The dynamically generated gains from the PDT are further processed by RT-OP to compute optimal setpoints every 15 minutes. Unlike the APC model, the RT-OP model generates dynamic gains and captures a broader range of gain relationships between various process variables, some of which may not be explicitly considered in the APC model. As a result, the gain matrix produced by the RT-OP exhibits higher sparsity compared to APC gain models, allowing for a more holistic optimization approach with a wider range of dynamic gain relationships.

Fig-02: High-fidelity PDT model

Optimization Results with Yokogawa’s RT-OP

Yokogawa's RT-OP system ensures that LNG plant operations consistently remain in an optimized state by providing dynamically updated setpoint targets to the existing APC system. The high and low limits of APC-controlled variables are always synchronized with the corresponding limits in the RT-OP system. This synchronization ensures that RT-OP operates strictly within the predefined APC constraints, optimizing process performance without exceeding operational boundaries.

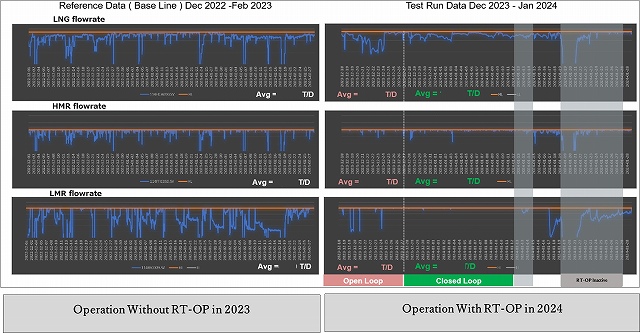

A comparison of actual plant data trends before and after RT-OP implementation demonstrates its effectiveness. Trends for key process variables such as LNG flow and refrigerant flow show that, following RT-OP deployment, LNG flow increased while the refrigerant flow had minimal fluctuations and operated closer to its upper APC limit. This improvement is reflected in a reduced standard deviation for these variables, highlighting RT-OP’s capability to enhance process stability, maximize plant throughput, and optimize energy efficiency.

The provided RT-OP system is designed to be highly flexible, enabling optimal operation even at minimum available feed gas flow rates. It ensures maximum utilization of the LNG plant not only during periods of sufficient gas availability but also under turndown conditions, when feed gas supply is limited. As long as the APC system remains in operation, the RT-OP system can be effectively utilized to optimize plant performance across varying operating conditions.

The trends shown in fig-03 illustrate the optimized behavior of the variables. During closed-loop operations, these trends show that variables are close to the APC upper limit and are fully optimized.

Fig-03: Variable trend comparison of RT-OP operation with base line period

Value Addition with Yokogawa’s RT-OP & PDT

The Yokogawa and OLNG teams jointly assessed the actual realized benefits of the Yokogawa RT-OP and PDT solutions. The performance of the RT-OP system was evaluated in both the summer and winter periods. It was observed that, during the summer, when ambient temperatures are relatively higher, the MR compressor power becomes an active constraint for the RT-OP system. However, in winter, this constraint is no longer present, allowing for greater operational flexibility. The following table shows the benefit of using the RT-OP solution under varying seasonal conditions.

Table-01: Benefit by Yokogawa RT-OP based on solution availability

Yokogawa and the OLNG team expect greater benefits by extending this solution to the entire facility (train, upstream, downstream).

Additional Advisory Benefits of PDT

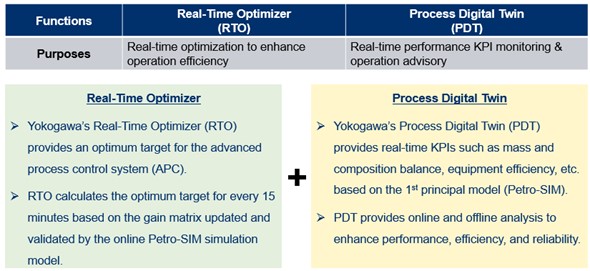

Yokogawa’s solution extends beyond closed-loop optimization by integrating a high-fidelity, first-principles-based PDT. Fig-04 below illustrates the multipurpose utilization of this solution.

Fig-04: Multipurpose utilization of single solution

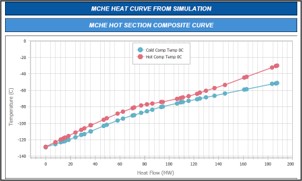

The Yokogawa Advisory PDT is directly connected to real-time plant operational variables, generating an updated PDT model every two hours. This solution incorporates a built-in plant steady-state detection system, ensuring that unsteady plant conditions do not affect the PDT results. The advisory system provides preconfigured key performance indicators (KPIs) that are seamlessly displayed on an integrated dashboard, which is an integral part of the solution. It covers real-time plant mass and heat balance calculations, as well as efficiency monitoring for major equipment such as compressors and turbines. Additionally, it allows for detailed analysis of the impact of MR composition on MCHE performance. The following case study results are based on actual plant data and demonstrate the effect of MR composition on MCHE performance.

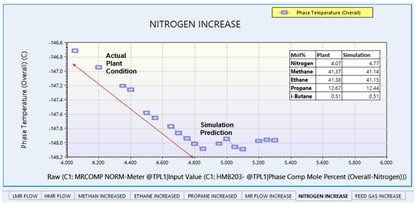

Fig-05: N2 mol% in MR effect on rundown temperature

In LNG plants, process engineers typically use offline simulation models that require frequent updates with current plant data. With Yokogawa’s solution, simulation cases can be automatically generated from the PDT, providing process engineers with a true representation of real-time plant conditions. This enables engineers to efficiently perform more accurate "what-if" and scenario-based analyses, without the need for extensive manual data updates.

RT-OP & PDT Solution Monitoring with Integrated Dashboard

Yokogawa’s solution includes an integrated dashboard for real-time monitoring of the RT-OP and PDT system, displaying customized plant KPIs. The RT-OP solution can be tracked not only in terms of its optimized results but also by identifying constraints that may be limiting further optimization. With the assistance of RT-OP, process engineers can leverage the PDT model to analyze whether these constraints can be adjusted to improve performance. Additionally, the dashboard provides real-time steady-state detection results, ensuring accurate representation of plant stability, which is further utilized by the PDT model. It also facilitates comprehensive monitoring by generating mass balance reports, evaluating equipment efficiency, and visualizing MCHE cooling curves. This solution offers the flexibility to monitor the system at both the control room and corporate levels. Sample dashboard views from the project are shown below.

Comprehensive Dashboard for Solution Monitoring

A structured and comprehensive KPI dashboard has been developed, integrating key performance indicators derived from PDT, RT-OP, APC, and distributed control system data. The KPIs are systematically categorized and summarized for efficient monitoring and analysis.

Fig-06: MCHE monitoring overview

Fig-07: Plant stability monitoring

Fig-08: RT-OP benefit tracking

Fig-09: Real time mass & composition balance

Fig-10: MCHE composite curves

Customer’s Voice

At Oman LNG, we are committed to embracing innovation that enhances operational excellence and sustainability. Over the course of a year-long Proof of Value (PoV), we partnered with Yokogawa to explore the potential of their Process Digital Twin and Realtime Optimization technologies through a partially scoped implementation. This collaboration was marked by a shared vision, agility, and a strong spirit of partnership.

The Yokogawa team demonstrated a deep understanding of our operational needs and worked closely with our engineers to tailor the solution to our specific context. Their responsiveness and technical expertise were instrumental in refining the system to align with our performance goals. The final evaluation of the PoV revealed that the technology was able to optimize our production, a result that underscores the tangible value of this digital initiative. This achievement is not only a testament to the capabilities of the technology but also to the collaborative approach that defined the project.

We look forward to further leveraging digital innovation to support our mission of delivering sustainable energy for a better world.

OLNG Team Members

The following members of the OLNG team actively shared their knowledge of plant operations and helped to maintain and evaluate the benefits of Yokogawa’s solution. Yokogawa would like to express their gratitude for their contributions.

Ahmed Al Oraimi, Principal Process Control and Automation Engineer - Oman LNG

Mr. Al Oraimi served as the RT-OP Project Manager and Technical Authority. With over 19 years of experience in process control, automation, APC, and instrumentation, he brings deep technical leadership and strategic oversight to complex optimization initiatives.

Khalid Al Aamri, Lead Process Control and Automation Engineer - Oman LNG

Mr. Al Aamri has over a decade of experience. His expertise spans procedural automation, base layer control, APC, real-time optimization, and change management. He played a key role in implementing real-time process optimization, with a focus on APC improvements. He holds a degree in Electrical and Electronic Engineering from Duisburg-Essen University in Germany.

Dr. Saud Al Dhouyani, Lead System Engineer – Oman LNG

Dr. Al Dhouyani holds a Ph.D in data analysis and processing (AI and fuzzy logics) and has more than 15 years’ experience in oil and gas industry automation systems design, implementation, and integration.

Azza Al Dhuhli, Senior APC Engineer – Oman LNG

Ms. Azza holds a degree in Chemical and Process Engineering from Sultan Qaboos University and is a skilled and versatile APC engineer. She focuses on identifying operational constraints, maintaining APC KPIs, and ensuring applications meet design standards. She also develops and delivers automated startup procedures and has led multiple projects in base layer control, APC, and procedural automation. She is a certified Apollo RCA Facilitator and an active member of the ISA, APC, and procedural automation communities. She played a key role in collaborating with Yokogawa to ensure the success of the OLNG RT-OP project.

Related Industries

-

Chaîne D'approvisionnement

YOKOGAWA s'est engagé dans l'automatisation du GNL en fournissant les derniers capteurs, analyseurs, systèmes de contrôle et d'information depuis plus de 50 ans, depuis que le GNL a été importé pour la première fois au Japon. YOKOGAWA est l'un des plus grands fournisseurs d'automatisation de la chaîne d'approvisionnement mondiale du GNL, de la liquéfaction, du transport et de la regazéification.

Les produits et solutions liés

-

Dynamic Real Time Optimizer (RT-OP)

Dynamic Real Time Optimizer (RT-OP) optimizes assets and asset operations in a refinery or petrochemical plant to ensure that they are continuously responding to market signals and disturbances.

-

Real-time optimization for LNG plants with process digital twin

Maximize production efficiency under varying conditions by integrating process digital twin and real-time optimization technologies with your existing process control systems (DCS/APC).