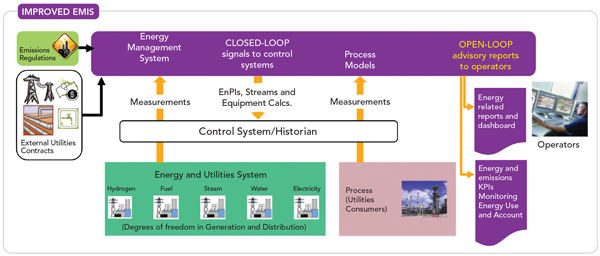

Yokogawa Energy Management Solution is a holistic system that continuously monitors energy consumption and provides active real time control to minimize energy cost. It facilitates energy consumption analysis, drill down analysis, what-if analysis, debottlenecking, modeling and simulation that enables quick and effective strategic decision making.

-

Enterprise Energy Management Services

A cloud-based energy management service that manages the energy consumption of utilities and energy processes without the need for extensive and expensive equipment modifications.

-

Energy Monitoring

Improving manufacturing efficiency demands constant action. From uncovering operational waste to identifying areas for continuous improvement, we must always pursue a cycle of visualizing, analyzing, and solving energy saving challenges. Together, Yokogawa and KBC offer the solutions and services needed to overcome your energy monitoring challenges.

-

Combustion Safety & Optimization

Yokogawa is proud to offer a single source solution to improve combustion safety and efficiency in fired heaters.

-

Renewable Energy Management System

The management of distributed energy resources like solar and wind presents significant opportunities for enhancing grid stability and efficient power delivery. Properly addressing these challenges can facilitate the seamless integration of additional renewable resources, enabling the achievement of clean energy goals.

-

Energy Efficiency

Whilst European businesses have been transforming to capture continuous, year-on-year, energy savings … deeper savings are required … requiring deeper digitalization of energy

Details

Ressources

Adding process considerations improves energy savings and production performance.

Rechercher plus d'informations sur nos compétences, technologies et solutions

Contactez-nous