Unlock the full potential of upstream facilities – powered by Yokogawa’s digital twin and optimization technologies

Maximize production efficiency across the entire upstream facility under diverse conditions by leveraging Yokogawa’s process optimization technologies.

In upstream oil and gas operations, maintaining stable and profitable performance is a top priority—but it is also a major challenge. Each section of the facility, from wells and separators to sulfur recovery units and more, faces fluctuating conditions and uncontrollable external factors that make optimization complex.

Yokogawa’s comprehensive solution addresses these challenges by enabling full-facility optimization, powered by a robust digital twin engine. The system operates 24/7, 365 days a year, continuously simulating, monitoring, and adjusting processes to maximize production efficiency while ensuring safety and asset integrity.

Whether you are managing a single well or an integrated upstream network, Yokogawa’s digital twin-based optimization delivers measurable value—reliably, securely, and at scale.

Details

Challenges

Key challenges in oil & gas upstream operation

Unstable field conditions impacting operations

Reservoir pressure, fluid composition, and temperature can fluctuate unpredictably. These dynamic conditions make it difficult to maintain stable operations and require continuous adjustment of control strategies.

Fragmented operations across units

Upstream facilities consist of multiple interconnected units. While local optimization is common, achieving true end-to-end optimization across the entire facility remains a complex challenge.

Efficiency vs. safety constraints

Maximizing production and profitability in high-risk environments is challenging, due to the need for strict adherence to safety and equipment protection standards.

Solutions

Yokogawa realizes upstream facility-wide optimization with process digital twin technology

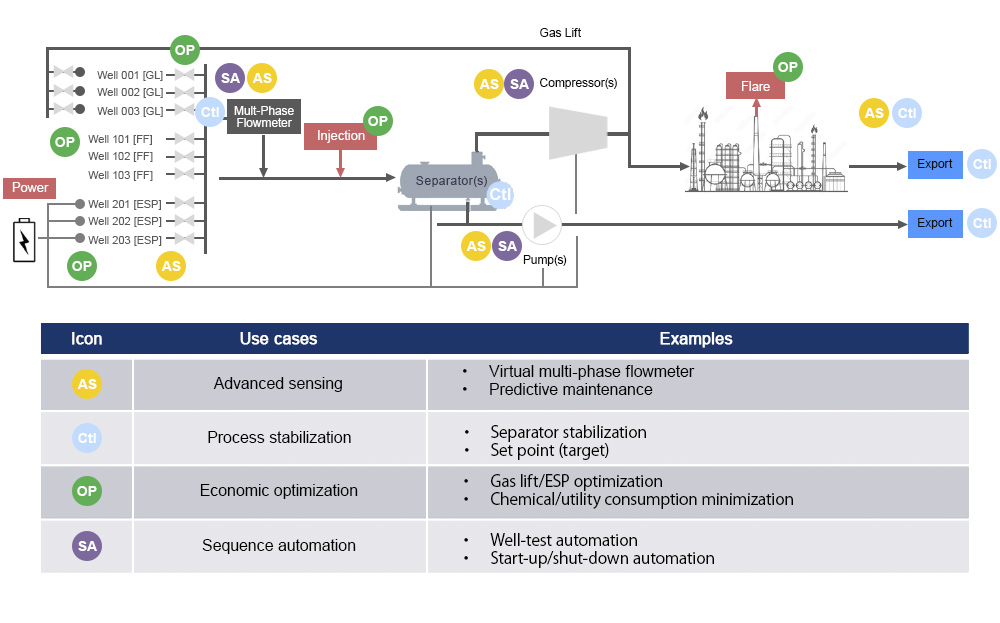

Advanced soft sensors

Yokogawa’s soft sensor technology provides advanced sensing for anomaly detection and real-time property estimation.

Process stabilization

Yokogawa’s platform for advanced control and optimization achieves stable control even under unstable conditions.

Economic optimization

Yokogawa’s process digital twin and optimization technology unleashes the facility’s potential.

Sequence automation

Yokogawa’s modular process automation technology eliminates manual operations during transient conditions with a low-code/no-code tool.

Benefits

Yokogawa’s real-time optimization provides both tangible and intangible benefits

Operational excellence

- Maximized process efficiency

- Early detection of abnormalities

- Stable operations

Economic value

- Maximizing asset utilization and profitability

- Revenue enhancement

- Improved ROI

- Minimized product losses

Environmental & sustainability impact

- Reduced energy consumption while maintaining target production levels

- Continuous performance optimization driven by a 24/7, 365-day operational agent

Looking for more information on our people, technology and solutions?

Contact Us