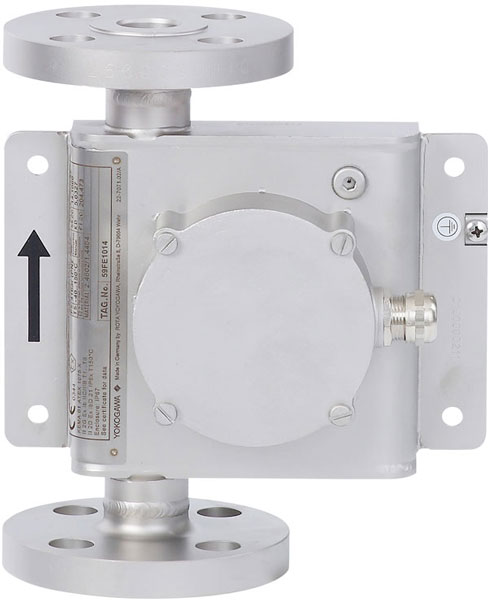

ROTAMASS is the integral and remote type Coriolis Mass Flow Meter. Both types have highly refined digital signal processing electronics, so that accurate and stable mass flow measurement is achieved.

Coriolis Flow Meter ROTAMASS employs a flame-proof type converter case suitable for use in the hazardous area together with its intrinsically safety type detector.

Coriolis Flow Meter ROTAMASS's signal processing, housing protection and its detector's special decoupling system against external loads and vibrations, realize high performance in real applications.

Details

The RotaMASS 3 Series mass flow meter features a heavy wall, seamless, dual tube design uniquely decoupled from any process vibration or pipeline stress guaranteeing reliability and output stability. Nine different detectors enable customization of the meter for the best combination of mass flow range, pressure drop, and accuracy at the lowest possible cost. The versatile RotaMASS can be used in the most difficult applications from cryogenics to molten liquids as well as sanitary applications and aggressive chemicals. With its multi-measurement and multi-parameter capability, the RotaMASS is essentially a process control station. The state of the art converter provides a wealth of features including remote configuration via HART, multiple languages, advanced diagnostics, infrared programming and a four-line display for easy setup and operation.

- Field transmitter for nearly all fluids

- Refined digital signal processing enables accurate and stable measurement

- High accuracy and high stability over a wide range

- A special detector coupling system makes the device highly independent from external loads or vibrations

- Wide temperature range -200 deg C to 350 deg C

1: Revolutionary box-in-box design

Complete decoupling from vibration and stress

Complete decoupling from vibration and stress

- Rugged reliability

- Immune to vibration

- Stable output in the most demanding applications

- Install anywhere versatility

The ROTAMASS advantage

- Simple, patented box-in-box design mechanically decouples measurement tubes from process vibration and mechanical stress

The benefits to you

- High performance assured in real world applications

- High reliability and output stability

- The ability to mount ROTAMASS where you need it most, even directly on pumps and engines

- Easy to install even when piping is slightly misaligned

2: Superior drainability

Keeps maintenance to a minimum and maximizes uptime

Keeps maintenance to a minimum and maximizes uptime

- Simple self-draining design

The ROTAMASS advantage

- Simple flow-path: no flat sections or 90˚ angles that can trap process fluids, sediments, and gas bubbles in measurement tubes

- No need to shut down process to clean tubes

The benefits to you

- No stalling or dropouts/increased uptime

- Excellent zero point stability and improved accuracy

- Lower maintenance costs

3: Durable heavy-wall construction

Stable performance whatever the application

- Rated for high line pressures

- Highly resistant to corrosion and abrasion

- Stable output assured in all process conditions

The ROTAMASS advantage

- Thick, seamless measurement tubes rated for process pressures up to 280 bar (4000 psi)

- Higher resistance to corrosion and mechanical abrasion

- The 150 Hz excitation frequency possible with the thicker tube avoids interference from process vibration in the 40-60 Hz range and prevents problems such as liquid separation and damage to complex / cellular structures that can happen at frequencies about 500 Hz.

The benefits to you

- Increased safety

- The ability to measure a wider range of process fluids, even aggressive chemicals, under all kinds of operating conditions

- Longer lifetime and lower maintenance costs

- Minimal pressure effects, for greater accuracy

- Greater ease of installation and improved stability of output

4: Lighter and smaller

|

| Click to enlarge |

Easy, low-cost and flexible installation

- Lightweight design

- Small footprint

The ROTAMASS advantage

- The lightest product in its class - does not require special installation equipment or expensive additional supports

- The most compact coriolis mass flow meter on the market

The benefits to you

- Reduced installation cost and time

- The ability to install ROTAMASS where you need it most

5: Advanced diagnostics

State of the art detection of entrained gas and corrosion

- Utilizes the latest digital signal processing technologies

The ROTAMASS advantage

The ROTAMASS advantage

- Mass flow output stays steady and true with high levels of entrained gas

- Slug flow (large gas bubble) causes a sudden and prolonged shift in density and drive gain. Mass flow output stays steady and true.

- Automatic corrosion detection

- A long-term fluid density error triggers a corrosion alarm when the fluid density reaches a predefined level

The benefits to you

- Accuracy that you can depend on in the most critical custody transfer applications

- Early detection of piping failures and optimum scheduling of maintenance operations

- Refined digital signal processing enables accurate and stable measurement

- Simple flow path means self-draining, food capable and simple to clean

- High accuracy and high stability over a wide range

- Accurate density measurement, up to +/- 1 g/l

- Two analog outputs, 2 pulse outputs or status-out and one status-in as standard I/O

- Available in Explosion Proof versions

- Wide temperature range -200 deg C to 350 deg C

- Microprocessor-based multifunction capability

- EEPROM protects parameter settings and totalized values

- During power failure of any duration

- High visibly LCD display

- HART communication function

- Intrinsically safe outputs as an option

- Several tube materials available

- EN or ANSI flanges as standard

- Other process connections on request

Fast, Simple and Accurate ROTAMASS Coriolis Flow Meter with Modbus Interface

ROTAMASS expands communication capabilities

The successful ROTAMASS 3 expands its communication capability with the widely used Modbus interface.

Modbus communications via an RS-485 connection will be available in both Modbus RTU and ASCII transmission modes. The fast and simple Modbus communication at up to 57 kbit/s enables access to all relevant process measurements including - but not limited to - mass/flow, density and temperature. All measurement variables are included as readable address registers. In addition to the Modbus communication, the standard I/O interfaces such as 4-20 mA, pulse/frequency and status in/out are still available for control and/or monitoring purposes.

The ideal solution for multivariable measurement providing simple and fast access of all process data

- ASCII and RTU, 1200..57000 bps over RS485

- Point to Point and Multidrop Network

- Full ability to program meter measurement configuration

- All measurement variables available as readable address registers

- Simultaneous configuration via HART or Indicator possible

- Additional Outputs available

- 4-20 mA

- Pulse/Frequency

- Status In/Out

- Free Modbus Communication Tool

ROTAMASS LR - the world's smallest dual bent tube Coriolis mass flow meter

The new ROTAMASS LR continues the tradition of the proven dual bent tube and self-draining design and extends Yokogawa's ROTAMASS Low Flow Line for gas and liquid flow measurement in an extraordinary manner.

Key features are:

- Dual bent tube design in perfect balance for optimum decoupling of the core measuring element and independent performance from installation conditions

- Robust and all stainless steel housing with highest rupture pressure of ≥ 65bar in low flow Coriolis market

- Unique inline temperature measurement for unaltered mass flow and density measurement

- Most precise measurement by insulating from unsteady process environment conditions

Resources

- RotaMASS was chosen to work with weight measurements and/or differential pressure transmitters for extremely accurate measurements.

- The customer recognized the product's advantages: reliability, accuracy, guaranteed draining system, easily cleaned system, no moving parts, directly built into the pipelines, low pressure losses.

- CENTUM CS 3000 plays key role in Malaysian waste oil to diesel project.

- Yokogawa proposed to provide its systems and services as the main instrument vendor.

- As the main automation contractor (MAC) for this plant construction project, Yokogawa Brazil engineered, installed, and commissioned an integrated control and instrumentation solution

- Yokogawa Brazil completed the commissioning of these systems ahead of schedule and the production of green polymer was started just one week later

- OTS for familialization of liquefaction processes and operator training.

- Yokogawa's integrated solutions contribute to safe and steady production at gas liquefaction plant in Norway.

A power plant in the Northeast was under pressure to meet State EPA requirements of reporting fuel consumption (used for emissions monitoring). The issue was digging a costly trench from the pump house to the control room building in order to run fiber optic cable that delivers a flow meter signal to the plant's historian where reports could be generated. The cost would be $20,000.00 alone to dig the trench.

Flow measurement of high pressure hydraulic fluid to servos to monitor leaks can translate to huge savings. However, measuring these fluids can be difficult due to the high pressures involved and entrained air, moisture and contamination.

Liquid Nitrogen, Carbon Dioxide, Argon, Oxygen, and LNG/LPG are some examples of cryogenic fluids which are perfect for a Coriolis mass flow meter. Their fluid properties change wildly with small variances in temperature or pressure. The biggest problem is that most meters on the market literally freeze up and stop working when metering these fluids.

Molten sulfur, bitumen, pitch, paint resins and liquid toffee are just a few of the fluids transported at high temperature. Their fluid properties change wildly with small variations in temperature, which presents a problem for most metering technologies, while the coriolis flow meter is perfect for such measurements.

Flow Measurement of diesel fuel is a relatively basic flow meter application. However, measuring net fuel consumption on a 2.2 megawatt diesel generator is uniquely complex. The diesel engine requires a supply fuel line (fuel from the tank to the engine) and a return fuel line (fuel from the engine back to the tank).

Fossil fuels have long been used as a heat source in power generation. Coal is one of the more common fuels, but environmental concerns have led to a great deal of time, effort and money being spent on the reduction of pollutants resulting from the use of coal.

Necessary oil is a family owned oil re-processor with a presence in the states of Tennessee, Virginia, North Carolina, South Carolina, West Virginia, Kentucky, Indiana, Ohio, and Pennsylvania. A fleet of trucks pick up used oil and discarded coolant from oil change shops and industrial users.

The Coriolis flow meter has many features such as direct measurement of mass flow and measurement of fluid density, which other flow meters do not support. Therefore, since being introduced for practical use in the late 1970s, its market has rapidly expanded in many industries such as oil, chemicals, and foods.

Downloads

Instruction Manuals

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter (18.8 MB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter with Foundation Fieldbus communication (8.2 MB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter with Modbus communication (2.9 MB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter for Custody Transfer Applications (2.4 MB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter for NTEP Custody Transfer Applications (183 KB)

General Specifications

Drawings

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter RCCT34...39/XR (1.2 MB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter RCCS34...39/XR (992 KB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter RCCF31 (390 KB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter RCCY03 (269 KB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter RCCS30…33 (610 KB)

- ROTAMASS 3 series Coriolis Mass Flow and Density Meter RCCR31 (784 KB)

News

-

Press Release Mar 5, 2012 ROTAMASS Coriolis flowmeter with Modbus interface

Looking for more information on our people, technology and solutions?

Contact Us