For decades, industrial control systems have played an important role in industrial automation by allowing process manufacturers to collect, process, and act on data from the production floor. Currently, these systems are in transition. Ongoing technological and industry developments have paved the way for new roles for two process control systems: the Distributed Control System (DCS) and the Supervisory Control and Data Acquisition (SCADA) system.

This article explores the roles of DCS and SCADA in digital transformation (DX). It provides a brief overview of these industrial control systems as well as Programmable Logic Controllers (PLCs) before delving into the evolving roles of DCS and SCADA amid industry transformations and projected future developments. Finally, the article touches on how Yokogawa can help businesses improve industrial automation through DCS and SCADA solutions.

Background on DCS and SCADA

Process manufacturers typically employ DCS and SCADA technologies to monitor and control the operations in their facilities. The DCS was designed to replace individual, analog and pneumatic loop controllers, which were cumbersome when applied to very large processes such as refineries. SCADA originated as a solution for operations that span broad geographical areas, for example, pipelines and utilities. Later, a variant that uses a human-machine interface (HMI) in conjunction with PLCs evolved for plant automation applications.

However, DCS and SCADA systems are now doing much more than simply monitoring and controlling. They are integrating with additional intelligence at every level of industrial automation architecture to facilitate predictive asset life-cycle management and value chain optimization while advancing the stakeholder experience and improving security and safety. Although this particular industrial control system transition is already underway, the larger transformation of industrial automation systems has only recently begun.

![]() Distributed Control System (DCS)

Distributed Control System (DCS)

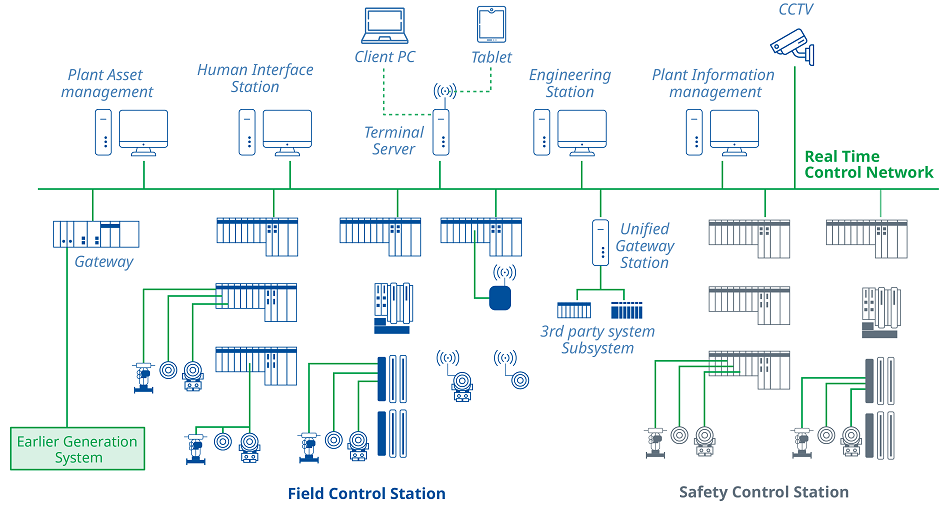

At its core, a DCS is a platform for the automated control and operation of an industrial process or plant. A DCS uses local area networks (LANs) to interconnect sensors, actuators, controllers, and operator terminals for process control. This type of system emerged as a digital replacement for analog and pneumatic controllers in process operations. It originally served the need to control large continuous processes such as refining and petrochemicals but was subsequently extended to batch processes as well.

At its core, a DCS is a platform for the automated control and operation of an industrial process or plant. A DCS uses local area networks (LANs) to interconnect sensors, actuators, controllers, and operator terminals for process control. This type of system emerged as a digital replacement for analog and pneumatic controllers in process operations. It originally served the need to control large continuous processes such as refining and petrochemicals but was subsequently extended to batch processes as well.

![]() Supervisory Control and Data Acquisition (SCADA)

Supervisory Control and Data Acquisition (SCADA)

Although SCADA systems originated by serving applications that require broad geographical area coverage, the concept evolved with the inception of PC-based HMIs, which replaced more expensive minicomputers in the 1980s. Instead of a wide area network that interfaces with remote terminal units (RTUs) at locations such as pump stations, a typical in-plant SCADA system uses Ethernet for communication between the HMI and PLCs. In the latter category, the SCADA system architecture shares many similarities with DCS architecture. In the former category, a SCADA system can connect corporate operations with multiple plants, each of which uses a DCS. Process manufacturers can use these enterprise-wide systems for data communications without facing geographical restrictions.

Essentially, DCSs and SCADA systems both play important roles in plant automation. Despite this similarity, however, key differences separate these two types of systems.

![]() What are the differences between DCS and SCADA?

What are the differences between DCS and SCADA?

The differences extend far beyond the fact that a traditional SCADA system is able to work with a wide area network whose bandwidth is much lower than that in a DCS LAN.

A key distinction is that a DCS uses distributed workstations for operator HMI. Each workstation is able to communicate directly with controllers on the DCS LAN. In a SCADA system, all communications between HMI workstations and PLCs will funnel through a server. Thus, the server is a single point of failure, which could render the entire process essentially invisible to all users.

While the architecture of a DCS and a SCADA system might otherwise appear to be identical, the DCS includes numerous, often subtle features such as redundant electronic circuits, which increase the system availability and minimize downtime. Redundancy extends to remote I/O. All remote I/O electronics and the communication networks between them and the DCS controllers are, or at least, could optionally be redundant. A PLC, on the other hand, is designed to minimize the hardware cost.

While SCADA HMIs and servers are typically commercial off-the-shelf (COTS) PCs, a DCS uses non-COTS components that are optimized to the task. In addition, in a DCS, the Windows operating system is kept isolated from the process. This enhances cyber security. A deterministic DCS LAN guarantees that a critical message such as a high priority alarm, will, indeed, arrive at its destination. The SCADA system typically relies instead on the high bandwidth of the LAN.

Since a single DCS vendor typically supplies the entire system, components such as controllers and workstations are more tightly integrated than they are in a SCADA system. Common benefits include simplicity or reduced engineering costs. Still, for a given process, a DCS will be more expensive than a SCADA system. In processes for which unplanned shutdowns are very costly, the price difference is justified. While SCADA suppliers could deploy redundant servers or high availability computing (HAC) platforms to make those systems more reliable, their availability will not be as high as that in a DCS.

![]() PLC vs DCS

PLC vs DCS

One advantage of a PLC vs. a DCS is the processing speed. A PLC typically offers significantly shorter cycle times to scan I/O points and execute control and logic operations. Although DCS and PLC technology has largely converged, their origins are completely different. While the DCS evolved from analog and pneumatic PID loop controllers, the PLC was originally a replacement for hard-wired relay logic panels. In discrete logic processing, speed is of the essence. A PLC will perform such logic processing much faster than would a DCS.

The DCS was designed for continuous PID loop control in process industry applications. In those applications, the PLC provides much less of an advantage in cycle processing time. An application with a combination of continuous control and discrete logic control will typically use a DCS for the former and a PLC for the latter. Often, the DCS will integrate with a PLC, which has been supplied on a skid-mounted process unit such as a turbine-driven centrifugal compressor. Some DCS vendors have developed very efficient interfaces for such situations.

![]() DCS, SCADA and the Automation Pyramid

DCS, SCADA and the Automation Pyramid

DCS and SCADA systems both comply with the ISA95 Purdue reference model architecture. The first level - the field level - of the automation pyramid includes devices, actuators, and sensors on the production floor. The second level - the control level - uses PLCs and Proportional Integral Derivative (PID) controllers that interface to field-level devices. As part of the third, or supervisory, level of the automation pyramid, SCADA systems traditionally act as data funnels, transporting a broad variety of information for process control, asset management, historical analysis, and IT applications. A DCS will often use multiple servers - which could be part of or considered to be a SCADA system - to communicate with corporate and IT systems.

DCS and SCADA systems both comply with the ISA95 Purdue reference model architecture. The first level - the field level - of the automation pyramid includes devices, actuators, and sensors on the production floor. The second level - the control level - uses PLCs and Proportional Integral Derivative (PID) controllers that interface to field-level devices. As part of the third, or supervisory, level of the automation pyramid, SCADA systems traditionally act as data funnels, transporting a broad variety of information for process control, asset management, historical analysis, and IT applications. A DCS will often use multiple servers - which could be part of or considered to be a SCADA system - to communicate with corporate and IT systems.

A modern DCS or SCADA system will interact with several software and hardware components. Each resides in the first and second levels of a manufacturing control operation and pulls together all five levels of the automation pyramid. Because of this, it acts as the glue for digitalization, quickly facilitating a flow of information through processes from the plant floor to the boardroom.

Evolving role of DCS and SCADA with digital transformation

While DCS and SCADA are unique, both of these system types are undergoing transformations in line with broader DX trends, such as the confluence of the Industrial Internet of Things (IIoT). This transformation comes with the promise of improved industrial automation capabilities and value for process manufacturers.

New challenges that end users have brought to light have prompted vendors to consider how it would be possible to reimagine operational technology (OT) automation systems using Commercial-off-the-shelf (COTS) and information technology (IT) components. End users require that vendors incorporate best-in-class COTS hardware and software to create automation systems that surpass the reliability, security, and end-user value of today’s DCSs.

They also desire a system that enables them to preserve their control strategies by porting them into upgraded or new systems. In addition, end users have requested modularized hardware elements - computing, networking, storage, and I/O terminations, for example - to allow for incremental upgrades. Finally, they would like software that has been decoupled from the hardware and I/O to allow execution anywhere in the system.

![]() How is digital transformation changing DCS and SCADA?

How is digital transformation changing DCS and SCADA?

In an effort to leverage new digital technologies to meet these customer challenges and expectations, forward-looking process manufacturers are investing in DX. DCS and SCADA are ultimately part of ongoing DX efforts and, as a result, are evolving alongside all other process manufacturing technologies.

Changes to DCS and SCADA systems fit within the ongoing transformation of the automation pyramid. Amid DX, the automation pyramid is evolving. IT/OT convergence and virtualization technologies, for example, are blurring the distinctions between the pyramid’s levels and enabling the migration of some engineering and software applications to the cloud.

With the integration of cloud technologies, process control systems are able to perform edge computing and serve as robust data sources for the IIoT. Cloud-based environments facilitate the convergence of data across multiple sources and improve data availability to support insightful decision-making and application interoperability.

![]() What are the requirements for SCADA and DCS in digital transformation?

What are the requirements for SCADA and DCS in digital transformation?

In order to take advantage of cloud technologies, the IIoT, and edge computing, process manufacturers need to modernize their aging automation systems. On the whole, the drive toward DX has created a need for more open and secure system architecture and design.

![]() Increasingly open systems

Increasingly open systems

The NAMUR Open Architecture (NOA) and Open Process Automation Forum (OPAF) are driving major open architecture initiatives in industrial automation and prompting a shift away from proprietary architectures. Both initiatives describe vendor-neutral systems that allow the use of state-of-the-art equipment and functions at all times and the continued use of proprietary software applications in the future.

A key OPAF objective is to transition away from vendor lock-in, which has historically been an issue with large DCSs. The requirements for the architecture currently being considered by OPAF are "interoperability," "modularity," "standard conformity," "compliance with security standards," "scalability," and "portability."

In the case of NOA, an independent domain called M+O (Monitoring and Optimization) is prepared separately from the existing system, and data is directly collected from robots, drones and new sensors, for example, for corrosion, sound, and vibration. Furthermore, data in the existing system is imported by OPC UA, and advanced control, analysis and diagnosis can be realized even in the field. From the viewpoint of security measures, compatibility with zone design recommended by IEC62443 is enhanced, and system design and maintenance can be easily performed.

More problematic is a lack of continuous upgrades from some DCS vendors. If their vendor ceases to provide upgrades, manufacturers are compelled to resort to a rip-and-replace approach, in which the old system is completely replaced by an entirely new one. In this scenario, the production loss and costs incurred while transitioning to the new system often far outweigh the system cost. By creating an open, interoperable specification, OPAF aims to foster the development of less-expensive and improved process control systems.

![]() Increased security

Increased security

DX has created a need for secure network architecture and design in addition to increased openness. Security is especially important as IT/OT convergence and new technologies, such as cloud computing, introduce new security risks.

Meanwhile, ongoing system evolution is actually mitigating some system security risks. For example, in SCADA systems, field devices have traditionally connected to RTUs, which provide data consolidation and translation. RTUs have been key targets in cyberattacks on SCADA systems. Older RTUs often use insecure communication protocols. Increasingly, however, new technology trends are phasing RTUs in favor of Edge devices.

Since exposing data to the Internet presents security risks, it is vital that process manufacturers keep their SCADA systems up-to-date using contemporary cybersecurity resources. The International Society of Automation’s (ISA) 62443 series of standards, which the International Electrotechnical Commission (IEC) has adopted, and the National Institute of Standards (NIST) 800-16 offer helpful resources and guidelines for network administrators and cybersecurity engineers.

Since their data exchanges typically rely on radio or public communication infrastructure, SCADA systems are more vulnerable to cyberattacks. As SCADA systems oversee wide area networks, there are more points of entry. Meanwhile, a DCS is not completely secure from cyberattacks and requires comprehensive measures, particularly on entry points into LANs.

![]() Cybersecurity

Cybersecurity

Cybersecurity is a common denominator among all technologies. The cybersecurity strategy and implementation approach based on the Purdue model now extends throughout the enterprise. A new standards-based approach has been designed to encompass IT and OT systems. While OT typically uses the NIST cybersecurity framework, IT requirements and interactions with third parties could involve additional standards, such as ISA/IEC 62443 and ISO 27001.

While integrating IIoT technology, IT/OT convergence implementation teams will continue making decisions regarding the segregation of OT networks from corporate networks, OT network isolation from the Internet, least privilege access controls at site and process levels, and cross-site communication restrictions. Meanwhile, cyber security domain expertise is evolving to encompass the formerly disparate OT and IT domains.

![]() Current trends in digital transformation regarding to DCS and SCADA

Current trends in digital transformation regarding to DCS and SCADA

Generally speaking, two key, intertwined DX goals for process manufacturers are greater connectivity and flexibility. These are driving demand for smart factories that leverage IIoT technology. Process manufacturers are seeking to optimize production, and systems are changing as a result.

One example of this shift is taking place at a technical level in the efforts to implement smart manufacturing, which have spurred the adoption of fieldbuses. Vital to the IIoT, fieldbuses are dedicated networks designed for mission-critical control and sensing functions. Fieldbuses originated as replacements for analog, 4-20mA current loops.

Hard-wired fieldbuses such as HART, Profibus/Profinet, and FOUNDATION Fieldbus, provided field device diagnostic capabilities to manufacturers. Subsequently, manufacturers began to opt for wireless technology in a condition-based maintenance (CBM) approach. This wireless technology provides the data that is necessary to support the IIoT and optimize entire value chains.

As DX continues to create new expectations for connectivity and flexibility, continued system transformation is sure to follow.

What does the future look like for DCS and SCADA?

Requirements for open architecture and enhanced cybersecurity, driven by DX, are likely to continue shaping future DCS and SCADA developments. As stated in the introduction, these systems are currently in transition, but the DX journey of industrial automation systems has really only just begun. This journey comes with challenges for process manufacturers—for example, upgrading a legacy system can seem incredibly daunting at the outset. But the potential benefits of DX make addressing such challenges more than worthwhile.

DX promises to bring a new era in industrial automation. In this era, machines will be able to execute complex control functions with self-learning capabilities and minimal operator intervention. This will allow process manufacturers to reduce accidents and production downtime resulting from human error and achieve optimal plant operation.

As part of DX, DCS and SCADA systems will support web services, IIoT and cloud-based connectivity such as Open Platform Communications United Architecture (OPC UA), Message Queuing Telemetry Transport (MQTT), and IT connectivity such as that provided by Simple Network Management Protocol (SNMP) and Internet Control Message Protocol (ICMP) to monitor IT assets.

With greater system connectivity, integrated operations centers (IOCs), and dynamic operator guidance made possible by high-quality alarm systems, process manufacturers will be able to achieve new levels of system optimization and safety. Digital twin solutions offer process manufacturers improved opportunities for process optimization. These dynamic simulators allow manufacturers to consider changing operating conditions and predict process behaviors in advance. In turn, this enables improvements in production safety and flexibility.

How Yokogawa can help

Process manufacturers seeking to optimize production and embark on a DX journey do not need to do so alone. A partner with a combination of domain knowledge and technical skill can provide invaluable guidance throughout a DX project.

Yokogawa has proven control technology and offers a range of innovative automation architectures, efficient control strategies, and advanced solutions. For more information on how Yokogawa can help process manufacturers adapt and upgrade their systems in line with changing marketplace demands, please explore the company’s control system solutions and DX & Digital Twin solutions. And download the “Control System Selection Key Criteria” white paper. Yokogawa is well suited to help set process manufacturers up for a bright future with new industrial automation possibilities.

Kapcsolódó termékek és megoldások

-

Collaborative Information Server(SCADA)

Collaborative Information Server (CI Server) allows immediate improvement to production efficiency through DX (digital transformation) and reduction of operational maintenance whilst building a digital transformation framework.

-

Digital Twin

A digital twin is the key to effective decision making, providing deeper analytics technology and strategies to maximize profitability.

-

Digitális transzformáció

With Yokogawa's wide knowledge of and expertise in process manufacturing, Yokogawa can help bring about the realization of a digital transformation that will lead to a better future for its customers.