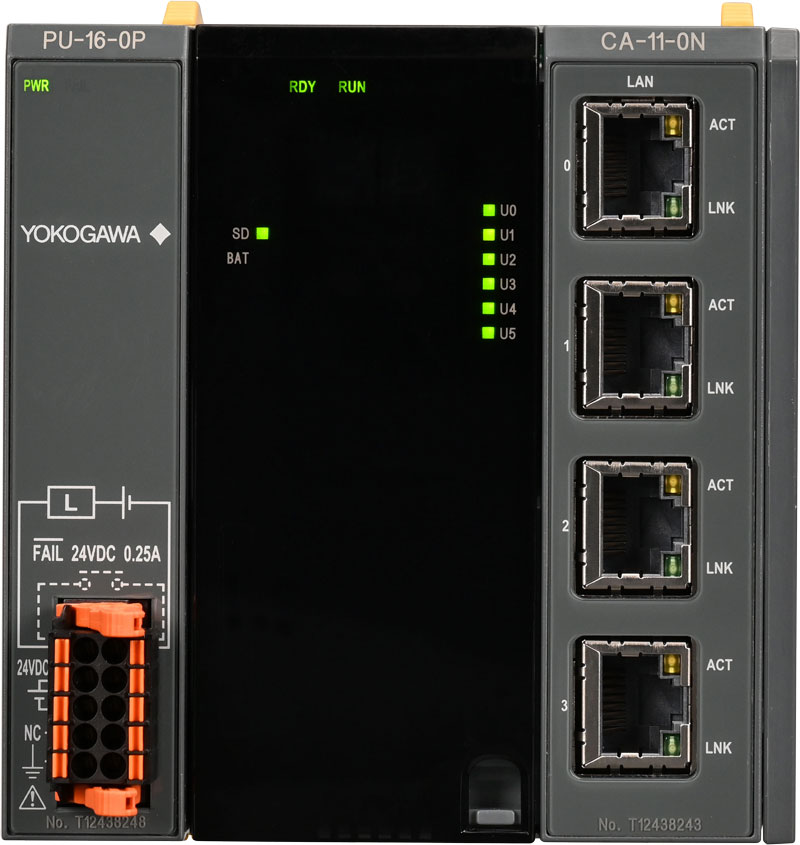

The OpreX Intelligent Edge Controller A8 is a Linux-based embedded controller equipped with a high-performance Cortex-A53 processor.

It incorporates the proprietary abstraction interface, Data Stream, on robust hardware inherited from FA-M3 and e-RT3 platforms.

By enabling program development independent of the hardware specifications of controlled devices, it shortens development time and improves application reusability, allowing for flexible and efficient system development.

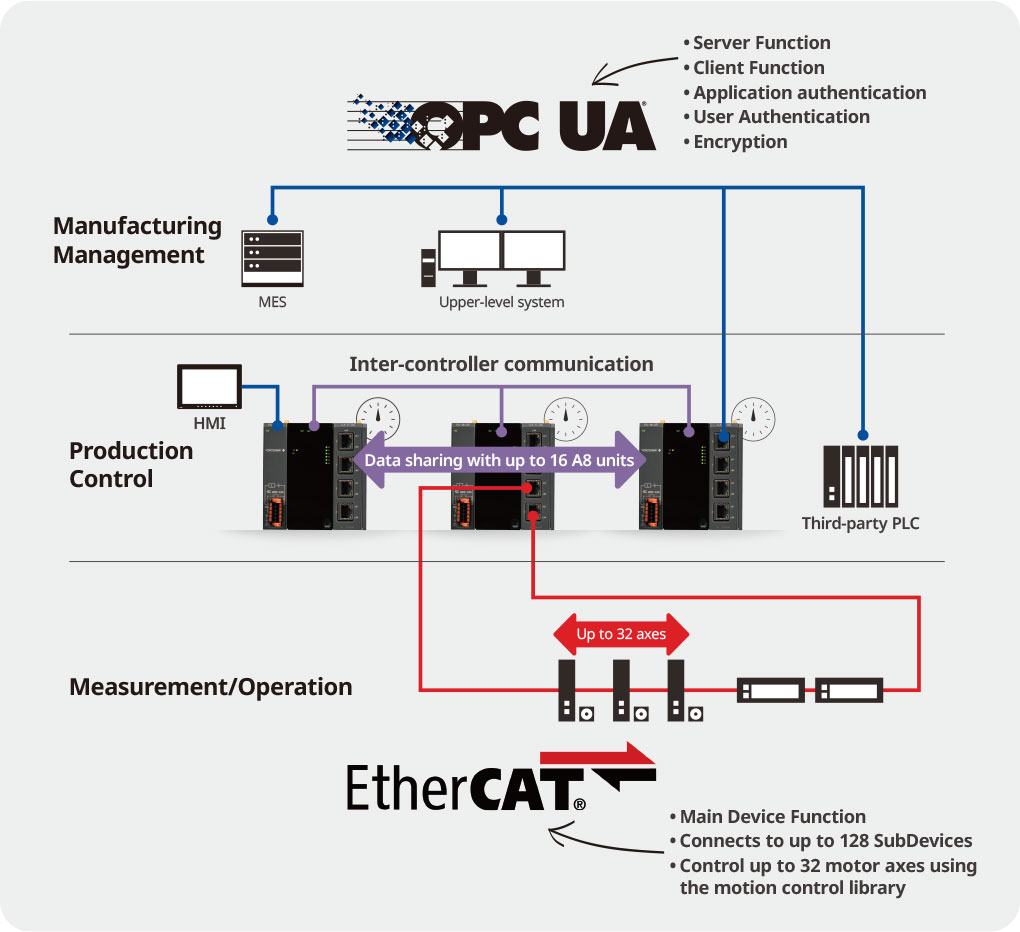

In addition, optional motion control library, PID control library, and EtherCAT Master device support a wide range of equipment control applications.

Features

High-performance processor-equipped Linux-based embedded controller

Equipped with an ARM processor (Cortex-A53 Quad core 1.2GHz), enabling high-speed and stable control.

Provides control functions as embedded equipment controller (selectable via option code)

Standard License (Option code /STN): Motion Control: 8 axes, PID Control: 16 loops

Advanced License (Option code /ADV): Motion Control: 32 axes, PID Control: 64 loops

Common: EtherCAT MainDevice Function (connects to up to 128 SubDevices)

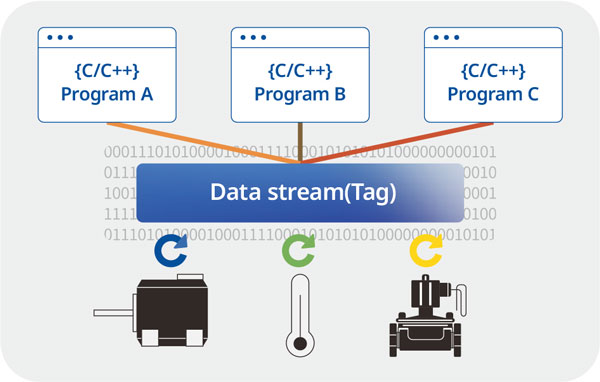

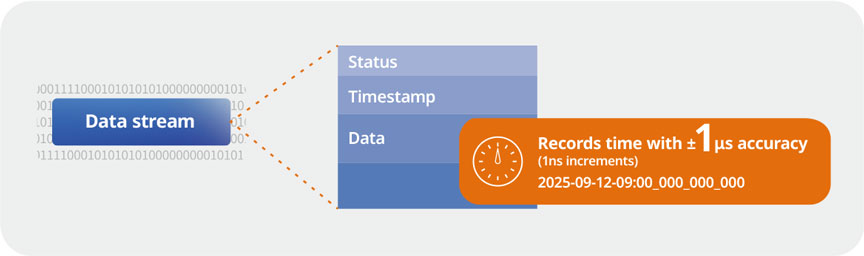

Features “Data stream” interface for hardware abstraction

Data stream is a device interface that separates software from hardware.

It streams data acquired by devices such as sensors, actuators, and communication services, constantly providing the latest information to programs.

Hardware and software are connected via tags on the data stream, enabling programs to be written without awareness of hardware specifications, thereby shortening development time and improving reusability.

De facto standard development environment

Visual Studio Code, which is widely used by programmers worldwide, is used as the development environment.

The development language supports C/C++.

Configuration tool

This configuration tool determines A8's operation, including data stream.

It enables assignments of data stream tags handled by data stream and communication settings. The configuration files generated by this tool synchronize hardware and software.

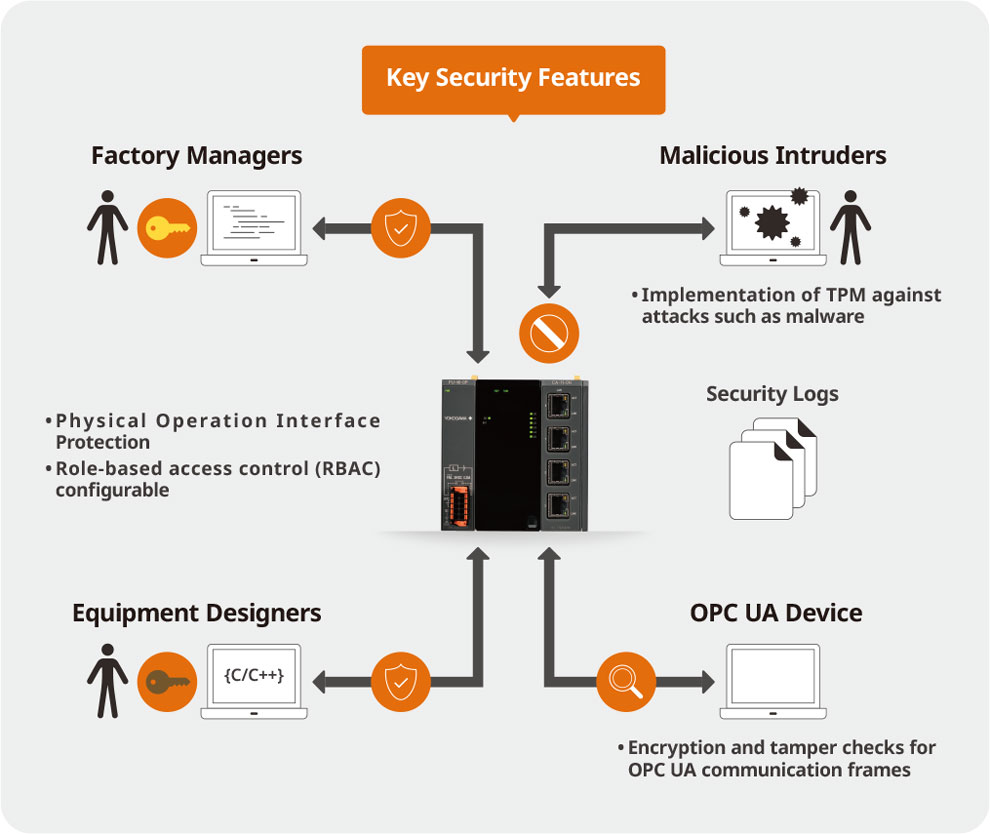

Robust security features

In addition to role-based login permission settings, features such as project file encryption and malware protection through TPM* implementation help protecting customer’s software assets and contribute to stable factory operations.

* TPM (Trusted Platform Module) is a security-specific hardware chip embedded in control devices.

Write only valuable programs

A8 adopts the data stream architecture, which centrally manages all information required for control. Data stream completely separates hardware and software dependencies, enabling parallel development of design and implementation. This significantly enhances development speed and flexibility.

Data stream

Data stream is a mechanism that automatically reflects input/output data such as I/O and communication data, enabling unified access from user programs. Programs access tag data associated with the device linked to the data stream, rather than the device itself, making data-centric programming possible.

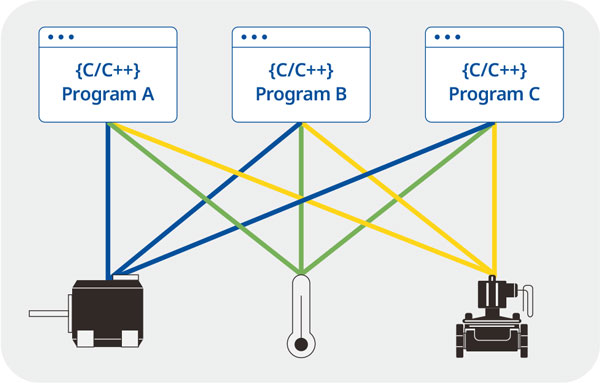

Relationship Between Programs and Hardware

Mechanism of existing controllers

Each program accessed via device-specific interfaces

Mechanism of A8

Access via interfaces optimized for each program

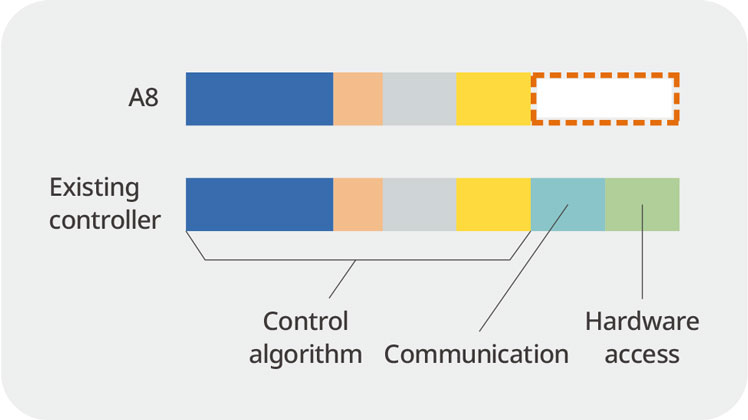

Programmers or Developers or Designers or something else that is specific can focus on building control algorithms

Programs no longer require "code necessary to run control algorithms," such as I/O settings or data acquisition.

Designers can concentrate on building high-value-added control algorithms.

Programs where reduction is expected

- Service initialization programs

No need to call API or configure procedures for accessing A8-specific services like various hardware or communications. - Event monitoring program

Data registered as event monitoring targets automatically notifies the program of any changes in their values. - Data Transfer Program within data stream

Using data transfer settings, data is transferred between tags without going through the program.

Code Reduction Concept

New form of real-time control

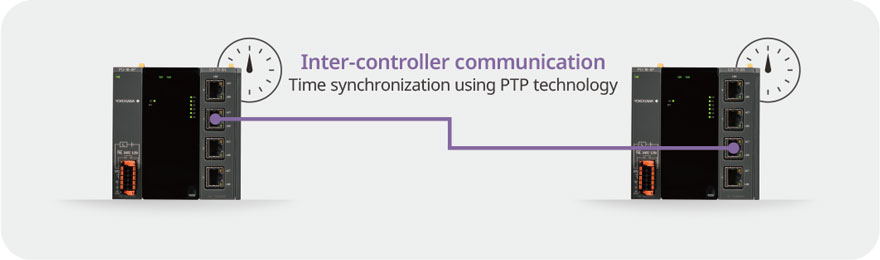

By inter-controller synchronization across and DC synchronization across EtherCAT devices, it enables high-precision control with ±1μs accuracy. This innovative synchronization technology precisely coordinates complex operations while maintaining time consistency across the entire control system. Furthermore, the stable control foundation provided by real-time control and the utilization of metadata like timestamps achieve unprecedented "time-sensitive control".

Timestamp

Since timestamps can be used as event triggers, processing can be based on the absolute "timestamp" rather than relative "time".

This eliminates the need for timers or counters for event monitoring, simplifying programs and reducing CPU load.

Inter-controller time synchronization

Time synchronization is possible up to 16 A8 units via inter-controller communication with time synchronization functionality. This synchronized A8 network allows each CPU to analyze device information updated by other CPUs in chronological order during its own processing. This enables distributed control that was unattainable with conventional control methods focused solely on detecting device changes.

Adopts globally standard networks

Adopts OPC UA and EtherCAT, widely used in factories worldwide. Provides secure communication with higher-level systems via OPC UA while delivering real-time control through EtherCAT.

Control security

Reliable security features safeguard stable operation and protect critical software assets.

In addition to role-based access controls, a Trusted Platform Module (TPM) is implemented to defend against malware and advanced cyberattacks.

This design delivers strong protection against external threats while remaining flexible enough to meet the increasingly stringent cybersecurity requirements expected of future manufacturing equipment.

About OpreX

OpreX Control Devices belongs to the OpreX Control category of the comprehensive OpreX brand for Yokogawa’s industrial automation (IA) and control business. In addition to various types of controllers, this lineup includes a number of related tools.

Details

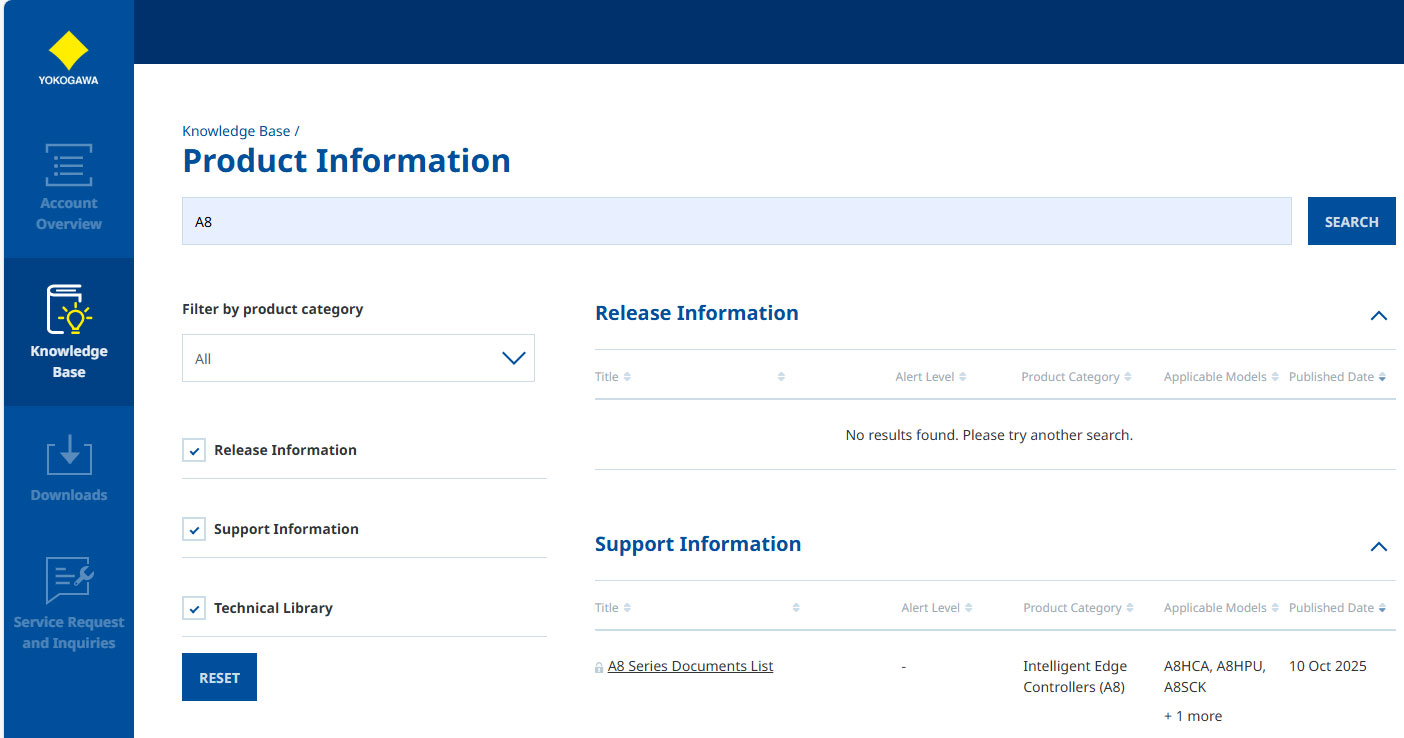

Notes on 「Downloads」 (A8 User Registration – Required)

Product content (documents and software) can be downloaded from the Yokogawa Electric Customer Portal (membership registration required).

After purchasing the product, please register your product by clicking "A8 User Registration" in the upper right corner of this page.

Note:

-To download product content, you will need both "Customer Portal Registration" and "A8 User Registration" on the Yokogawa Electric Site.

-When searching for content within the Customer Portal, please specify "A8" as your search keyword.

Software:<https://myportal.yokogawa.com/s/downloads>

Documents:<https://myportal.yokogawa.com/s/documents>

Product Information:<https://myportal.yokogawa.com/s/product-information>

Some documents can only be downloaded from the "A8 Document List" in the product information.

Links to some of the content are provided in "Downloads" at the bottom of this page.

CAD data can be downloaded from "Drawings".

Downloads

Brochures

Instruction Manuals

General Specifications

- A8 Overview (4.1 MB)

- A8 Standard Compliant Products (31 KB)

Technical Information

Drawings

- A8 A8HPU Power Supply Module 2D CAD (12.8 KB)

- A8 A8HPU Power Supply Module 3D CAD (258.5 KB)

- A8 A8HCA CPU Module 2D CAD (11.0 KB)

- A8 A8HCA CPU Module 3D CAD (454.3 KB)

- A8 T9132AA End plate 2D CAD (5.9 KB)

- A8 T9132AA End plate 3D CAD (33.2 KB)

Looking for more information on our people, technology and solutions?

Contact Us