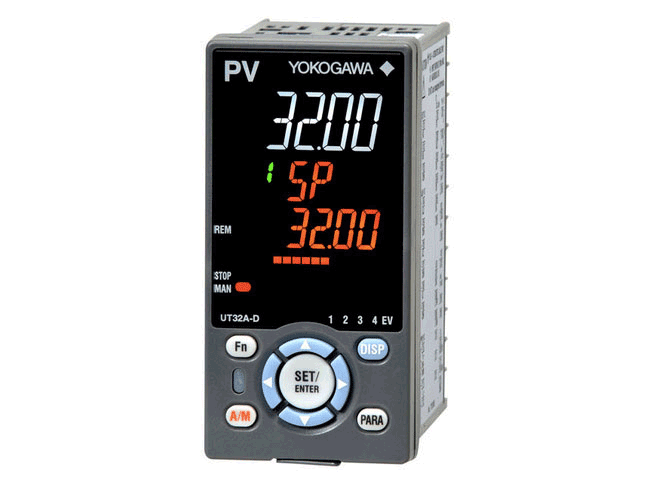

The UT32A-D is a compact digital indicating controller with selectable 2-loop control. It also includes a ladder sequence function.

CSA C22.2 61010-/1

UL61010-1

CE marking conformance available soon with the DIN rail mounted controllers

Features

Advanced Control

- Ladder sequence control

- Fuzzy logic control

Simplicity

- Easy-to-read, 14-segment large color LCD display

- Scrolling text feature for parameters

- Navigation guide & navigation keys

- Programmable funciton keys

- User settable default values

- Multiple language support (English, Spanish, French, German)

- Compact design of 65-mm depth

Networking

- RS-485 (Modbus/RTU, peer to peer, coordinated, PC-Link)

Reliability

- 3 year warranty*1

- RoHS/WEEE

- NEMA4*2/IP66 front panel

*1: The 3 year warranty extendes 36 months after shipment from our factory.

*2: Hose-down test only Application

Software

- LL50A parameters setting software with the ladder program building function (sold seperately)

- Panel and DIN rail mountable models are available.

CSA C22.2 61010-/1

UL61010-1

CE marking conformance available soon with the DIN rail mounted controllers

Details

-

List of RoHS

This is a list of recorder and controller products that support the RoHS (2011/65/EU) directive.

Resources

In the plants of food and beverage manufacturers, there are times when monitoring and recording of production equipment is necessary inside clean rooms. This is an introduction to monitoring and recording in clean rooms using paperless recorders.

Downloads

Brochures

Instruction Manuals

- UT32A-D Digital Indicating Controller (Dual-loop type) User's Manual (10.5 MB)

- UT32A-D Digital Indicating Controller (Dual-loop type) Operation Guide (3.9 MB)

- UT32A-D Digital Indicating Controller (Dual-loop, DIN Rail Mounting Type) Operation Guide (1.2 MB)

- UTAdvanced Series Communication Interface (Open Network) User's Manual (12.7 MB)

- UTAdvanced Series Communication Interface (RS-485, Ethernet) User's Manual (8.6 MB)

- Precautions on the Use of the UTAdvanced Series (286 KB)

- UTAP005 Wall Mount Bracket (964 KB)

General Specifications

Looking for more information on our people, technology and solutions?

Contact Us