Yokogawa delivers end-to-end Industrial decarbonization solutions in Europe to help energy-intensive sectors achieve carbon neutrality. Our integrated technologies enable measurable CO₂ footprint reduction while ensuring compliance with stringent EU emissions regulations, turning climate ambitions into operational reality.

Navigating Evolving EU Emissions Regulations

Europe's industrial landscape faces unprecedented regulatory pressure under the EU Green Deal and Fit for 55 package. Yokogawa's decarbonization solutions in Europe provide a clear pathway to compliance through:

- Real-time emissions monitoring aligned with ETS/CBAM requirements

- Automated reporting frameworks for carbon pricing mechanisms

- Future-proof strategies for evolving CSRD disclosure rules

We transform regulatory complexity into competitive advantage, ensuring your industrial emissions reduction initiatives meet both current and upcoming legislative benchmarks.

Accelerating Carbon Neutrality Across Europe

Yokogawa is committed to accelerating carbon neutrality by providing innovative industrial decarbonization solutions across Europe. Our expertise in process automation and energy management enables industries to:

|

Achieve net-zero

|

|

Reduce

|

|

Enhance

|

Our Decarbonization Solutions

Yokogawa is committed to accelerating carbon neutrality by providing innovative industrial decarbonization solutions across Europe. Our expertise in process automation and energy management enables industries to:

Carbon Management & Emissions Monitoring

Cloud-based services that calculate CO₂ emissions based on measurement data, facilitating accurate Product Carbon Footprint assessments.

Energy Optimization & AI-Powered Efficiency

Energy Optimization & AI-Powered Efficiency

Drive immediate industrial emissions reduction through AI-driven energy efficiency – slashing operational costs while accelerating CO₂ footprint reduction goals.

Hydrogen-Ready & Renewable Systems

Hydrogen-Ready & Renewable Systems

Enable cost-effective green hydrogen adoption: a cornerstone of Europe's carbon neutrality roadmap and essential for deep decarbonization.

Digital Sustainability & Industrial Autonomy

Digital Sustainability & Industrial Autonomy

Advanced analytics, edge computing, and integrated control systems for sustainable process automation.

Advanced Control Systems

Advanced Control Systems

Integrated solutions that enhance operational efficiency and safety while supporting decarbonization efforts.

Industries & Applications

Tailored decarbonization solutions for various industrial sectors

Renewable Energy

Implementing solutions that support the integration and management of renewable energy sources.

Oil & Gas

Strategies to reduce emissions and enhance efficiency in upstream and downstream operations.

Power Generation

Advanced solutions for cleaner and more efficient power production.

Chemical Industry

Optimizing processes to achieve sustainability goals in chemical manufacturing.

Digital Foundations for Carbon Neutrality

Yokogawa's GA10 data platform powers your decarbonization journey with:

- CO₂ footprint reduction tracking across Scope 1, 2 & 3 emissions

- Predictive analytics for proactive industrial emissions reduction

- Digital twins simulating net-zero transition pathways

Our technology stack turns sustainability data into actionable insights, ensuring your Industrial decarbonization solutions Europe deliver auditable results aligned with EU taxonomy criteria.

Why Choose Yokogawa

- EU emissions regulations expertise: Compliance-by-design in all solutions

- Proven CO₂ footprint reduction:

- 30-50% energy intensity decrease in refinery operations

- 25% emissions reduction in chemical processing

- Holistic carbon neutrality partnerships: From assessment to certification

Proven Leadership in Industrial Decarbonization

Yokogawa Europe has established itself as a leader by delivering innovative solutions that optimize energy use and enhance operational efficiency.

Integrated Digital Transformation Capabilities

Our comprehensive approach combines consulting expertise with advanced IT/OT integration leveraging IIoT and AI technologies.

Read more

Commitment to Sustainability Goals

Dedicated to achieving net-zero emissions by 2050 and transitioning to a circular economy aligned with global climate efforts.

Read more

Global Reach with Local Expertise

With a presence in over 60 countries, Yokogawa combines global experience with local knowledge to deliver tailored solutions that meet the unique needs of each client. Our regional teams are equipped to address specific challenges and opportunities in various markets.

Innovative Solutions for a Sustainable Future

Our portfolio includes cutting-edge technologies such as the OpreX Carbon Footprint Tracer, which provides precise calculations of product carbon footprints, aiding in compliance with regulatory standards and supporting sustainability reporting.

Read more

Accelerate your Path to Carbon Neutrality

Accelerate your path to carbon neutrality with Yokogawa's certified Industrial decarbonization solutions Europe. Contact our EU sustainability specialists to:

- Benchmark current emissions against EU emissions regulations

- Develop your tailored roadmap for industrial emissions reduction

- Implement scalable technologies for rapid CO₂ footprint reduction

Case Studies & Success Stories

Real-world examples showing emissions reduction and efficiency gains.

Total Feyzin Refinery – Site-Wide Energy Cost Reduction

Total Feyzin Refinery – Site-Wide Energy Cost Reduction

Yokogawa implemented an on-line model for site-wide energy system management at the Total Feyzin Refinery in France. This initiative led to significant reductions in greenhouse gas emissions and enhanced energy efficiency across the facility.

Read more

Aramis Carbon Capture and Storage Project

Aramis Carbon Capture and Storage Project

Yokogawa Europe was awarded a tender to provide Integrated Control and Safety Systems (ICSS), telecommunications, and system integration for the Aramis Carbon Capture and Storage Project. This project aims to significantly reduce CO₂ emissions in the industrial sector.

Read more

Port of Rotterdam – Energy Efficiency Feasibility Study

Port of Rotterdam – Energy Efficiency Feasibility Study

In collaboration with the Port of Rotterdam Authority, Yokogawa initiated a feasibility study to explore ways to increase cross-sector energy efficiency. This study focuses on optimizing energy use and reducing emissions in one of Europe's largest ports. Read more

Decarbonization Questions Answered

How can I reduce industrial carbon emissions?

Yokogawa offers integrated solutions that help companies monitor, control, and reduce their CO₂ emissions across the entire operation. Our carbon management tools provide real-time data so you can make smart, sustainable decisions that drive measurable results.

What is the best way to improve energy efficiency in my plant?

With Yokogawa’s energy optimization platforms, you can track energy usage in real time, identify waste, and make adjustments to save costs and lower emissions. These systems are built to deliver rapid ROI while supporting long-term decarbonization goals.

What technologies does Yokogawa use to help with decarbonization?

From AI-driven energy analytics to IoT-enabled sensors like the Sushi Sensor, Yokogawa combines cutting-edge technologies to support cleaner, more autonomous industrial systems. Our Industrial Autonomy initiative (IA2IA) is paving the way for future-ready operations.

Can I measure Scope 1, 2, and 3 emissions with Yokogawa?

Yes, Yokogawa provides robust tools to calculate and manage Scope 1 (direct), Scope 2 (indirect energy), and Scope 3 (value chain) emissions. These insights help you stay compliant and move closer to your sustainability targets with confidence.

-

Carbon Management Solution

We will tackle issues and collaborate with our customers to limit GHG emissions and shift to inexpensive, reliable, and sustainable energy using our original technology and know-how to achieve the goal of carbon neutral.

We contribute to the realization of a new recycling-oriented society that can coexist with the global environment.

Details

Carbon Management & Emissions Monitoring

Carbon Management Solution

Yokogawa's “Carbon Management Solution” is to achieve the goals of carbon neutral, we will tackle issues and collaborate with our customers to limit GHG emission and shift to inexpensive, reliable, and sustainable energy using our original technology and know-how. Yokogawa contributes to the realization of a new recycling-oriented society that can coexist with the global environment.

Read More

OpreX Carbon Footprint Tracer

A cloud-based service that calculates CO₂ emissions based on measurement data and other primary information, facilitating accurate and reliable Product Carbon Footprint (PCF) assessments in compliance with global regulatory standards.

Read More

Scope 1-3 Emissions Management

Tools to map potential paths to achieve emission reduction goals across Scope 1 (direct emissions), Scope 2 (indirect emissions from energy), and Scope 3 (other indirect emissions), offering a credible and technically rigorous approach to decarbonization.

Energy Optimization & AI-Powered Efficiency

Real-Time Monitoring and Optimization

Advanced platforms facilitate real-time monitoring and optimization of energy consumption, enabling industries to minimize waste and enhance energy efficiency.

KBC VisualMesa

An energy management system that provides visualization and optimization of energy systems, helping industries to reduce energy costs and emissions.

Read More

Online Energy Management

A refinery energy system is modelled, including all the constraints, with continuous model validation using live data. Performance monitoring includes the tracking of equipment efficiencies by utilising validated data for its continuous calculation.

Read More

Hydrogen-Ready & Renewable Systems

Future-proof operations against EU emissions regulations by optimizing renewable energy utilization across production ecosystems.

Hydrogen Solutions

Supporting the development of a data-driven and digitally-native energy system powered by renewables, including hydrogen-based solutions.

Read More

Waste to Energy and Biomass

Yokogawa is uniquely solving for variability in the European waste ecosystem; treating every item as a resource, to fully maximize its value. In doing so, helping to close loops for circular economies and reinforce industrial symbiosis.

Read More

Holistic Renewable Energy Solutions

Future-proof operations against EU emissions regulations by optimizing renewable energy utilization across production ecosystems.

Read More

Digital Sustainability & Industrial Autonomy (IA2IA)

Advanced analytics, edge computing, and integrated control systems for sustainable process automation.

Industrial Autonomy (IA2IA)

Yokogawa's initiative to transition from industrial automation to industrial autonomy, leveraging AI and digital technologies to optimize operations and reduce emissions.

Read More

Sushi Sensor

An IoT-based solution designed for real-time asset condition monitoring, helping to optimize plant performance and minimize downtime.

Read More

Advanced Control Systems

Integrated Control and Safety Systems (ICSS)

Solutions that integrate process control and safety systems, enhancing operational efficiency and safety while supporting decarbonization efforts.

Read More

Distributed Temperature Sensor (DTSX)

Advanced sensing technology that provides continuous, accurate temperature monitoring over large areas, enhancing safety and reliability in industrial operations.

Read More

Innovations in Action

Holland Hydrogen I – Europe's Largest Renewable Hydrogen Plant

Holland Hydrogen I – Europe's Largest Renewable Hydrogen Plant

Yokogawa has been selected as the Main Automation Contractor (MAC) for the Holland Hydrogen I project, which will be Europe's largest renewable hydrogen plant. The facility will feature a 200 MW electrolyser capable of producing up to 60,000 kilograms of green hydrogen per day, powered by electricity from an offshore wind farm. Yokogawa's role includes providing integrated control and safety systems to ensure efficient and safe operations.

Read more

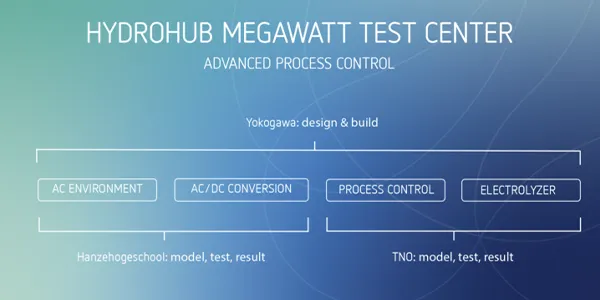

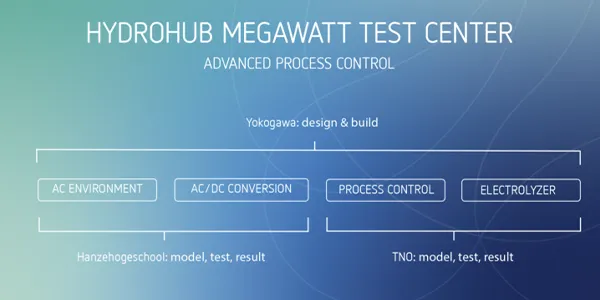

Hydrohub MegaWatt Test Centre – Advancing Green Hydrogen Production

Hydrohub MegaWatt Test Centre – Advancing Green Hydrogen Production

Yokogawa is actively involved in the Hydrohub MegaWatt Test Centre, a joint industry research project aimed at developing low-cost green hydrogen production methods. This open-innovation infrastructure facilitates testing and scaling of innovative technologies, contributing to the acceleration of the green hydrogen economy.

Read more

ORLEN Partnership – Sustainable Aviation Fuel Production

ORLEN Partnership – Sustainable Aviation Fuel Production

Yokogawa has partnered with ORLEN to develop cutting-edge technology for sustainable aviation fuel (SAF) production. This collaboration aims to accelerate the decarbonization of aviation fuels by integrating advanced process control and automation solutions, contributing to the reduction of carbon emissions in the aviation sector.

Read more

Frequently Asked Questions (FAQ)

1. What are the best industrial decarbonization solutions in Europe?

Europe’s leading industrial decarbonization solutions include real-time energy optimization, AI-driven process control, carbon footprint tracing, and hydrogen-ready systems. Yokogawa’s integrated technologies, such as the OpreX Carbon Footprint Tracer and VisualMesa Energy Management System, are helping industries reduce CO₂ emissions and align with the EU Green Deal.

2. How can manufacturers reduce industrial emissions cost-effectively in Europe?

Cost-effective CO2 reduction solutions for manufacturing involve predictive energy analytics, automated process tuning, and digital twins. These technologies optimize utility consumption and improve return on investment (ROI). Yokogawa solutions can reduce carbon footprints by up to 30%, with measurable ROI typically within 12–24 months.

3. What is the ROI of decarbonization technology in Europe for 2025?

The ROI depends on plant size, sector, and energy intensity. For most manufacturers, the payback period is under 2 years, especially when leveraging AI-powered tools and government-backed incentive programs under the EU emissions regulations and carbon neutrality frameworks. Yokogawa offers strategic planning tools to calculate your specific ROI.

4. How do industrial plants comply with the EU Green Deal and avoid carbon taxes?

Compliance with the EU Green Deal involves meeting energy efficiency targets, reporting Scope 1–3 emissions, and adopting low-carbon technologies. Yokogawa's digital platforms offer built-in tools for EU taxonomy alignment and carbon tax mitigation strategies 2024, reducing exposure to environmental penalties.

5. Which technologies offer the best energy efficiency for manufacturing in 2025?

Top-rated solutions include AI-powered energy management systems, edge-analytics sensors, and carbon footprint automation tools. Yokogawa’s Sushi Sensor and IA2IA strategy (Industrial Autonomy) provide real-time diagnostics, making them among the best energy-efficient technologies for manufacturing in 2025.

6. How can AI improve industrial decarbonization strategies in Europe?

AI enables smarter energy scheduling, predictive equipment maintenance, and automated load balancing, reducing both costs and emissions. Yokogawa integrates AI across its platforms to ensure consistent and scalable results for industrial decarbonization solutions in Europe.

7. What are hydrogen-ready decarbonization systems?

Hydrogen-ready systems are technologies that can be easily integrated with green hydrogen infrastructure. Yokogawa participates in projects like Holland Hydrogen I, providing automation and emissions control systems compatible with renewable hydrogen pipelines and net-zero manufacturing goals.

8. How do I implement carbon capture in the pharmaceutical industry?

Yokogawa supports carbon capture and utilization (CCU) through advanced process control, emissions measurement, and heat recovery systems. In pharmaceutical operations, we help integrate CCU technologies that meet strict validation and cleanroom requirements while reducing environmental impact.

-

A Wireless IIoT Solution Sushi Sensor

Sushi Sensor is a wireless solution for Industrial IoT (IIoT). It has excellent environmental resistance, and adapts LoRaWAN®, a wide area wireless communication method that realizes power saving and long-distance communication.

-

Carbon Management Solution

We will tackle issues and collaborate with our customers to limit GHG emissions and shift to inexpensive, reliable, and sustainable energy using our original technology and know-how to achieve the goal of carbon neutral.

We contribute to the realization of a new recycling-oriented society that can coexist with the global environment.

-

Fiber Optic Temperature Sensor DTSX

The DTSX fiber optic temperature sensor, which uses optical fiber for the temperature sensor, quickly detects and locates abnormalities in equipment by monitoring temperatures at production facilities located far away and across wide areas 24 hours a day, without omission. Highly accurate predictive maintenance avoids downtime and ensures stable plant operation.

-

OpreX Carbon Footprint Tracer

OpreX Carbon footprint Tracer (CFT) is a revolutionary service that calculates the carbon footprint of OT facilities and equipment throughout the supply chain. Leveraging energy-related data, raw material information, manufacturing specifics, shipping details, and more collected from factories, this cloud-operated service ensures precise measurement and reporting of Product Carbon Footprint (PCF) data, meeting regulatory standards.

-

Control and Safety System

Control and safety instrumented systems that support high efficiency, high quality, and safe plant operations. We provide solutions that support long-term stable production and enable a flexible and prompt response to changes in the business environment.

-

Enterprise Energy Management Services

A cloud-based energy management service that manages the energy consumption of utilities and energy processes without the need for extensive and expensive equipment modifications.

-

IA2IA

IA2IA is what Yokogawa foresees as the transition from Industrial Automation to Industrial Autonomy.

-

Combustion Safety & Optimization

Yokogawa is proud to offer a single source solution to improve combustion safety and efficiency in fired heaters.

-

Digital Transformation

With Yokogawa's wide knowledge of and expertise in process manufacturing, Yokogawa can help bring about the realization of a digital transformation that will lead to a better future for its customers.

-

Energy Efficiency

Whilst European businesses have been transforming to capture continuous, year-on-year, energy savings … deeper savings are required … requiring deeper digitalization of energy

-

Yokogawa Cloud

Yokogawa Cloud is a industrial transformation and IoT platform to accelerate the development and deployment of industrial cloud applications. Yokogawa engineers platform applications and solutions on behalf of customers. It supports the ingestion, processing, and curation of data from various sources, provides industry-specific algorithms and models and integrates across applications to support insightful decision-making and higher levels of automation.

-

Operations Management System

Yokogawa’s Operations Management System helps to ensure Safe and Reliable Operations by digitizing necessary information for Operation Management Practices.

Resources

A refinery energy system is modelled, including all the constraints, with continuous model validation using live data. Performance monitoring includes the tracking of equipment efficiencies by utilising validated data for its continuous calculation,

Hydrogen management can have a significant effect on refinery utility supply through the integration with the rest of the utilities. Real-time optimization of hydrogen production in conjunction with steam, power and fuels can yield significant savings opportunities for the refinery.

Yokogawa has been aiming at providing total battery solutions not only in the areas of research and development of batteries, but also in newly expanded areas such as their production, operation, secondary use, and recycling. Since 2011, these results have been provided for battery manufacturers and users as battery measurement solutions.

Downloads

Brochures

- Yokogawa Solutions for Renewable Energy (15.4 MB)

Videos

Looking for more information on our people, technology and solutions?

Contact Us

Energy Optimization & AI-Powered Efficiency

Energy Optimization & AI-Powered Efficiency Hydrogen-Ready & Renewable Systems

Hydrogen-Ready & Renewable Systems Digital Sustainability & Industrial Autonomy

Digital Sustainability & Industrial Autonomy Advanced Control Systems

Advanced Control Systems Total Feyzin Refinery – Site-Wide Energy Cost Reduction

Total Feyzin Refinery – Site-Wide Energy Cost Reduction Aramis Carbon Capture and Storage Project

Aramis Carbon Capture and Storage Project Port of Rotterdam – Energy Efficiency Feasibility Study

Port of Rotterdam – Energy Efficiency Feasibility Study Holland Hydrogen I – Europe's Largest Renewable Hydrogen Plant

Holland Hydrogen I – Europe's Largest Renewable Hydrogen Plant  Hydrohub MegaWatt Test Centre – Advancing Green Hydrogen Production

Hydrohub MegaWatt Test Centre – Advancing Green Hydrogen Production ORLEN Partnership – Sustainable Aviation Fuel Production

ORLEN Partnership – Sustainable Aviation Fuel Production