The wireless GX70SM remote data logger allows for quick and convenient data collection in areas that are not easily accessible or expensive to wire to.

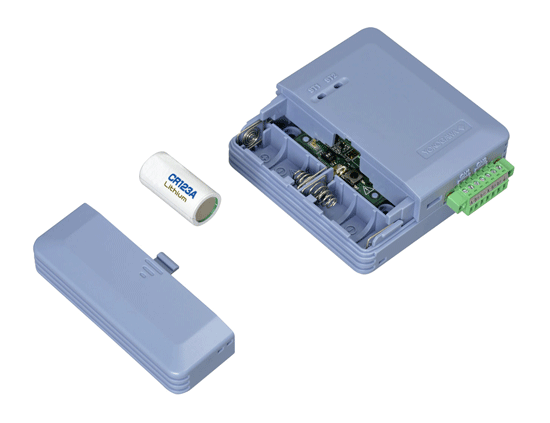

The GX70SM wireless input unit is a compact, battery-powered analog input module that uses 920 MHz radio link to connect to a SMARTDAC+ GX20, GP20, or GM10. The GX70SM allows for the collection of a variety of data points from locations that cannot be easily reached or are difficult and expensive to access. The optional humidity sensor and its simple mounting options makes this ideal for monitoring environmental conditions in areas like warehouses, clean rooms, and inside working environments where heat-related workplace injuries are a concern.

You now can see everything critical to your process: log key data points, monitor current process status, unreachable remote point, and more.

Application examples

- Pharmaceutical warehouse temperature mapping and continuous monitoring New

- Warehouse monitoring for temperature, humidity and door status.

- HSE monitoring for indoor workers at risk for heat-related illnesses.

- Remote monitoring of facility process operating status.

- Energy monitoring.

Note: The use of SMART 920 enabled units is limited to the United States, Korea and Japan. Please refer to the instructions for proper installation and use.

Details

Battery Powered

A pair of standard CR123 batteries will power the GX70SM module for 5 years when configured for a measurement once every 5 minutes. The module can also be powered from the USB port for long term or high speed data collection.

Displays the GX70SM battery status on trends, numeric, bar graph, and other monitor screens.

Multiple Inputs

The wireless module has 2 standard universal inputs and 1 dedicated input for relative humidity measurement.

The universal input channels support thermocouples, RTDs, DC voltages, current (with an externally mounted resistor) and digital inputs.

Input Calibration

The module inputs can be calibrated by the customer when routine calibration is required for compliance.

Secure Data

Wireless Terminal Authentication blocks unauthorized access. It also provides industrial grade AES-128 signal encryption to prevent tampering and wiretapping.

Can be installed in a variety of locations

- Can be hung on a wall screw.

- Can be directly mounted to a wall or their flat surface.

- Can be placed on any ferrous item with the strong embedded magnet.

- Can be placed on any flat surface.

Extensive self-diagnosis

- The status of the module can be displayed on the master unit. Conditions such as low battery and sensor burn out can be detected.

- The signal strength of the module can easily be detected by the base unit to assist in module placement.

Advanced data backup New

- In case of data loss due to communication failure, you can use the automatic backfill tool (application software) to compensate for the missing parts.

- The module can retain 9000 points* of logged data onboard.

- If the wireless connection is interrupted for any reason, the missing data can be restored from the GM70SMs memory.

* 30 days at a 5-minute scan interval

Validation documents New

- Additional verification protocols are available for the GX70SM wireless module. They can be combined with the SMARTDAC+ validation document (sold separately). You can reduce validation man-hours by using the GX70SM validation document, 773230/W.

You can visualize data in areas without power where environmental management is important.

Pharmaceutical warehouse temperature mapping and continuous monitoring New

The wireless input unit (GX70SM) provides a continuous temperature mapping and recording solution in product storage areas. Plus, it can continuously monitor risk points throughout the warehouse.

Clean room temperature and humidity control

The GX70SM wireless input unit is battery powered, has a built-in humidity sensor, and supports user-calibration.

Improve the factory working environment

Superior response to sharp temperature changes. Contributes to temperature and humidity control, and helps prevent heatstroke.

Measuring the WBGT value (heat index) with the SMARTDAC+

What is the WBGT (heat index)?

The GX70SM wireless input unit is battery powered, has a built-in humidity sensor, and supports user-calibration.

This is an index proposed in the US in 1954 for preventing heatstroke. A dedicated measuring device using a black bulb is required for accurate measurement, but in locations without direct sunlight such as factories and offices, the WBGT value can be easily determined from the temperature and humidity.

Flexible wireless communication

- Communication between the main unit and a SMART 920 remote unit can be established up to approximately 1 km in line of sight.

- The intelligent mesh network automatically recognizes unstable wireless links and re-routes data to a clear channel.

Reduced installation costs

Mounting conduit and pulling wire is no longer necessary. Installing a wireless solution greatly reduces installation time and costs.

Multiple mounting options

Wireless I/O components have multiple mounting options to match the conditions at the field location. Components can be DIN rail mounted, wall mounted, set on wall screws, set on a desktop, or attached to a ferrous surface with a magnet. These options provide for system flexibility allow changes to be quickly implemented.

Long distance data acquisition is possible

A 920 MHz wireless signal has a longer range than one in the 2.4 GHz band, typically used in wireless LAN applications. It has a greater reach around obstacles making it favorable for long distance or highly obstructed environments. Up to 0.5 mile line of sight.

You now can see everything critical to your process: log key data points, monitor current process status, unreachable remote point, and more.

-

920 MHz Wireless Data Acquisition

The SMART 920 allows you to collect data from your entire site without the high cost of wiring points to remote or unpowered locations.

Resources

Yokogawa Electric began offering the environmental monitoring system "OpreX Environmental Monitoring System" (hereinafter, OpreX EMS) for the pharmaceutical and medical device industries in October 2020. OpreX EMS, which was launched simultaneously domestically and overseas, is based on customers' needs, such as regulatory compliance, diversification of operational risks, and high usability. When asking the person in charge about the development history and features of the product, it was found that it is a new solution that meets the company's business vision.

Downloads

Instruction Manuals

- Model GX70SM Wireless Input Unit First Step Guide (Notes about Using This Product) (For the US and the Republic of Korea) (4.1 MB)

- Model GX20/GP20/GM10, UT52A/UT32A, UPM100 920 MHz Wireless Communication, MH920 Console International (For the US and the Korea) (11.6 MB)

- Model GX70SM Wireless Input Unit User’s Manual (4.2 MB)

- SMARTDAC+ STANDARD Hardware Configurator User's Manual (4.0 MB)

- SMARTDAC+ STANDARD Universal Viewer User's Manual (4.1 MB)

General Specifications

- GX70SM Wireless Input Unit (For the US) (2.1 MB)

- GX20/GP20 (/CM2 option) GM (/CM2 and /CS2 options) 920MHz Wireless Communication (2.3 MB)

- Model 773230 Validation Document for SMARTDAC+ (for the /AS option) (335 KB)

- GX20/GP20 (/CM3 option), GM (/CM3 and /CS3 options) 920MHz Wireless Communication (For Republic of Korea) (2.2 MB)

- GX70SM Wireless Input Unit (For the Republic of Korea) (2.2 MB)

Software

- Wireless Input Unit Configurator *Log-in Required

- MH920 Console International *Log-in Required

- GX70SM Input Module Firmware *Log-in Required

- GX70SM Wireless Communication Module Firmware *Log-in Required

- MH920 Wireless Communication module (Coordinator) Firmware *Log-in Required

- MH920 Wireless Communication module (Router) Firmware *Log-in Required

Drawings

- Model GX70SM Wireless Input Unit (689 KB)

Videos

Smart user interface, smart architecture, and smart functionality is achieved in the new Yokogawa SMARTDAC+ data acquisition and control product series. The Yokogawa SMARTDAC+ GX and GP are fully integrated measurement, display, and recording platforms equipped with an advanced touch screen operator interface. GX series is a panel-mount design, capable of operating in harsh industrial applications and environments. GP is the portable version of the GX, intended for use in lab and test bench applications.

YOKOGAWA creates autonomous operations with high-efficiency automation and optimization that allows growth with minimal deployment of manpower.

YOKOGAWA aspires to establish Smart GMP manufacturing facilities that provide consistent quality and supply while eliminating industrial waste, enhancing productivity and always using high-quality component parts and materials.

By equipping SMARTDAC+ with the advanced security features option "/AS", it meets the strict requirements of the U.S. FDA 21 CFR Part 11 and supports DI in compliance with PIC/S and ALCOA+ by WHO, MHRA and FDA.

Looking for more information on our people, technology and solutions?

Contact Us