Optimize lot, campaign, recipe, and grade management with KPI visualization, improving QCD

Integrated system will ensure reliability by linking design, operation, and analysis, also mitigating operational planning risks, quality inconsistency, and audit workload.

- Easily execute frequent recipe modifications

- Scheduler resilient to fluctuations in demand

- Inventory management to enhance profitability and product quality

- AI-enabled analysis to identify quality variations

- Ensure cybersecurity readiness

Details

Challenges

The acceleration of manufacturing risks due to diversified end-user requirements

Operational planning risks

- Complex schedules

- Inventory shortages and overstocks

- SOP lacking clarity

- Ineffective safety compliance

Quality inconsistency

- SOP allowing different interpretations

- Inconsistencies in manual data input

Audit complexity

- Time-consuming customer inquiries

- Audits managed through paper or files

- Cybersecurity concern/security concern

Solutions

Three effective measures to mitigate risks in production

Flexible planning

- Visualized schedules with easy plan adjustments

- Inventory visibility & management

- Simplified SOP creation

- Safety assurance through instrumented safety systems

Reliable execution

- Standardized SOP execution to eliminate interpretation gaps

- Automated data collection to reduce human error and input inconsistencies

- Integrated quality management ensuring uniform standards

- Centralized data integration

- AI-enabled analysis to detect deviations early

- Resolution of 4M issues (huMan, Machine, Material, Method)

Trusted Audit & Security

- Reliable records & traceability

- Flexible traceability to meet user requirements

- Robust cybersecurity measures

Benefits

Maximizing customers benefit with consistent quality

Accelerate time-to-market

- Reducing opportunity losses

- Optimized inventory

- Enhanced safety and reduced operational risks

Consistent quality

- Minimized rework and waste to achieve first-pass quality

- Elimination of quality variations via AI analysis

End-user reliability

- Automated electronic records make reducing workload and stress

- Reliable quality assurance

- Prevention of information leakage

-

OpreX Intelligent Manufacturing Hub 智慧製造平台 (RPA)

使用 OpreX 智慧製造平台為製造流程帶來變革。整合報告和視覺化各種數據,獲得即時洞察力,提高效率和獲利績效。

-

OpreX Batch MES C1-T1

使用 OpreX Batch MES C1-T1 優化化學品大量生產。無縫整合工作流程和管理流程,實現快速更新和高效營運。

-

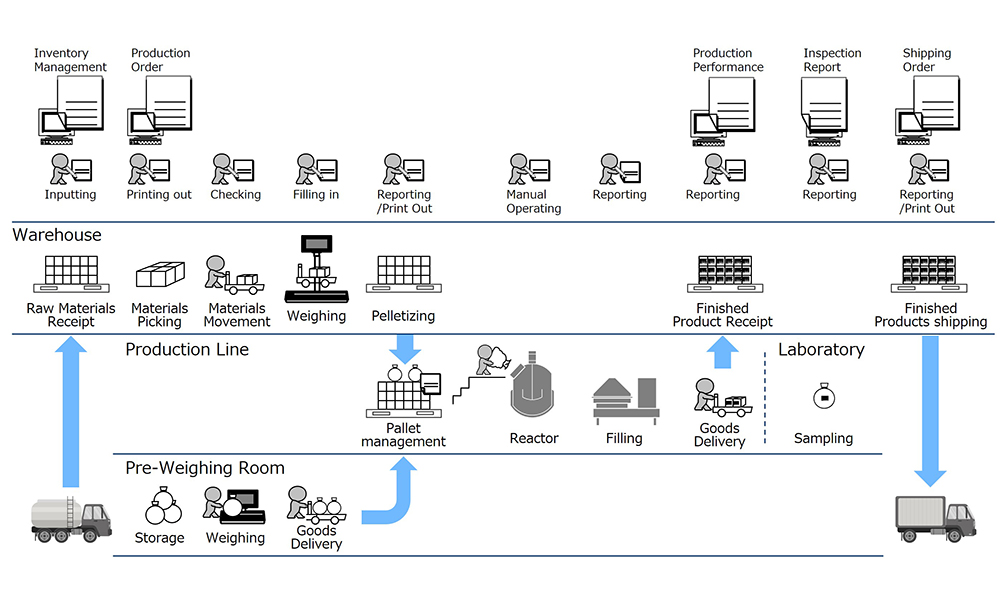

工作流自動化促進批量生產質量提升

借助橫河電機的自動化解決方案變革批量流程制造。通製無縫整合電子批次記錄(EBR)、倉庫管理系統(WMS)和實驗室信息管理系統(LIMS),實現實時決策、提升產品質量並優化運營流程。

-

CENTUM VP

CENTUM VP具有簡單而通用的架構,由人機界面、現場控制站和控制網絡構成。

-

批處理數據記錄系統(Exaquantum/Batch)

Exaquantum/Batch是基於ISA-88標準的智能批處理信息系統。可以提供驗證分析和報表工具,用於採集、保存和顯示批處理生產、設備和處方管理的當前和曆史數據。

想了解更多技術&解決方案嗎?

聯絡我們