Are You Having Any Problems like This?

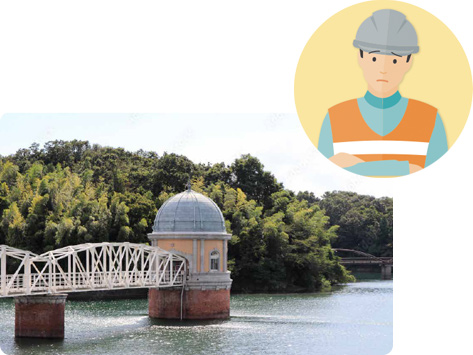

Equipment : Water treatment plants, water intake facilities, distribution reservoirs, and other water supply facilities

Problems : Unmanned facilities are widely dispersed, making data collection difficult.

- The intake facility is located far from the water treatment plant, requiring regular trips to measure data at the intake site, which is time-consuming.

- Even offices located far from water treatment plants and intake facilities want to grasp the local situation, but they are unable to do so.

- Data is scattered across water treatment plants and intake facilities, making comprehensive integrated monitoring impossible and making it difficult to detect where anomalies are occurring.

Easy to start using!

Wide Area Monitoring System solves remote monitoring issues

Facilities that exist in a wide area can be integrated and managed through remote monitoring.

The cloud can be used to reduce time and costs, and to efficiently build monitoring systems.

Value through Problem Solving

- By digitizing measured data from scattered intake points and distribution reservoirs and integrating it into a cloud-based monitoring system, operators can assess on-site conditions without physically visiting locations.

This reduces the burden of operator rounds. Operational status can be verified remotely from locations distant from the site.

- When measured data exceeds predefined upper or lower limits, an alarm notification is automatically triggered (alarm notifications are sent via email).

This allows monitoring of on-site conditions even from remote locations. - By integrating and monitoring data from all water supply facilities, we gain a comprehensive overview of on-site conditions.

This enables us to detect early signs of anomalies anywhere within the facility and take prompt action.

Proposed System Configuration

By centrally monitoring and managing water supply facilities such as water treatment plants, intake facilities, distribution reservoirs, and pumping stations through the cloud-based “Wide Area Monitoring System (WAMS),” we achieve operational efficiency and reduction in man-hours.

This enables real-time monitoring of equipment status and water quality at remote locations from anywhere, allowing early detection of anomalies and rapid response through the visualization of monitoring data. Furthermore, it reduces the time and cost required for personnel to visit sites.

Devices

| Category | Product |

|---|---|

| Cloud | Wide Area Monitoring System (Data acquisition interval: 5 min. or more, 50 measured data*) |

| Communication | Wireless Communication Connection License |

| Comm. devices/data acquisition | Data logger, Gateway, Recorder, Recorder gateway LoRaWAN gateway |

| Sensor | Flowmeter, Analyzer, Differential pressure level gauge, Sushi Sensor (Vibration, Temperature, Pressure) |

*With custom orders, collection cycles can be set to as short as 1 minute.

Related Industries

-

Water & Wastewater

Water resources are finite, and therefore contributing to a sustainable water cycle is one of the Sustainable Development Goals (SDGs). Yokogawa has been providing advanced digital control solutions for the stable supply of clean and safe water, wastewater treatment for protecting the water environment, water loss management and optimization of plant operation for reducing CO2 emissions and running costs. With our leading-edge technologies, dependable products and extensive expertise and experience of diverse water projects around the world, we work with you to provide sustainable water solutions that boost your business and add value throughout the plant lifecycle.

Yokogawa supports a wide range of water control applications in both the municipal and industrial water markets.

Related Products & Solutions

-

A Wireless IIoT Solution Sushi Sensor

Sushi Sensor is a wireless solution for Industrial IoT (IIoT). It has excellent environmental resistance, and adapts LoRaWAN®, a wide area wireless communication method that realizes power saving and long-distance communication.

-

Differential Pressure

Differential Pressure (DP) is defined as the difference between two pressures. Differential Pressure Transmitters use a reference point called the low-side pressure and compare it to the high-side pressure. Ports in the instrument are marked high-side and low-side.

-

Liquid Analyzers

Liquid analyzers are used for monitoring process chemistry including water quality, providing process optimization and control.

-

Modular GM10

SMARTDAC+TM GM10 data logger has a modular architecture that can acquire necessary data. By supporting not only I/O but also many communication protocols such as 920MHz wireless, Modbus and so on. Monitor and setting changes are available through Bluetooth. Supporting FDA 21 CFR Part11 and AMS2750E/NADCAP.

-

Touch Screen Paperless Recorder GX10/GX20

The SMARTDAC+TM GX10/GX20 is a panel mount paperless recorder with a modular architecture on the back panel and has a data logging function to acquire the required data. By supporting not only I/O but also many communication protocols, you can connect to various devices. GX utilizes AI. Supporting FDA 21 CFR Part11 and AMS2750E/NADCAP.

-

Vortex Flowmeters

Yokogawa has been synonymous with Vortex flowmeters since pioneering the industrial Vortex flowmeters from 1969. Even since then, Yokogawa has continued to be at the fore front of vortex technology; so, today, Yokogawa offers a large variety of Vortex flowmeters, including custom made designs.

-

Wide Area Monitoring System

The Wide Area Monitoring System helps you solve various problems occurring at operation sites by consolidating centralized/distributed data on the cloud for integrated data management and remote monitoring. No IT knowledge required. Start using the cloud with ease on a small scale!