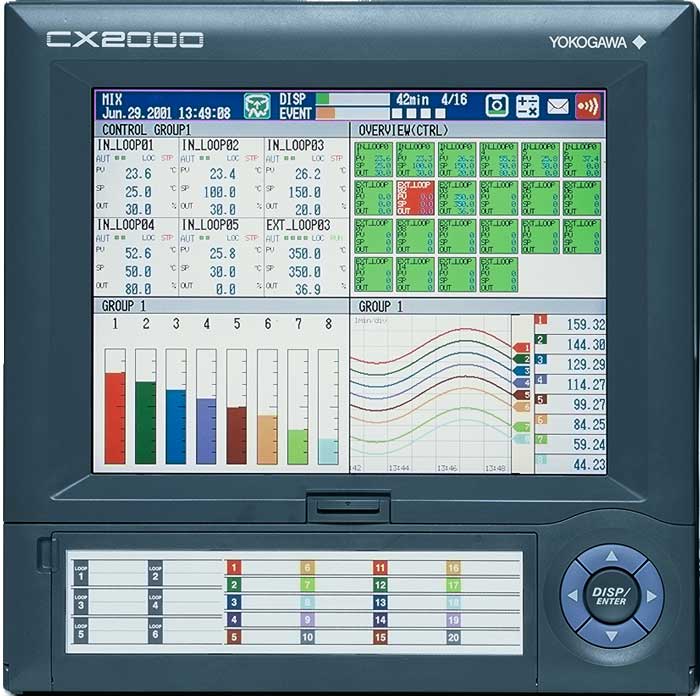

CX defines the next generation in process control by fusing recording, control and networking into a single, compact product. It delivers "Out of the box, ready to go" real-time and historical process monitoring. CX controls your process using internal PID loops and/or external controllers. One or more CXs link your process to the networked world with built-in Ethernet, web server, e-mail and FTP functions.

Resources

The Japan Steel Works, LTD., Muroran Plant uses the Control and Measurement Station CX2000, UP series program controllers, and UT series digital indicating controllers for operation of its heat treating furnaces. The Japan Steel Works (JSW), LTD., Muroran Plant is located in an industrial area looking over Muroran port in Muroran City, Hokkaido.

MEGTEC Systems, a major manufacturer of Regenerative Thermal Oxidizers in DePere, Wisconsin is now specifying DAQSTATION for use with their equipment. These oxidizers, commonly known as RTOs, are found in Paint Finishing Operations, Chemical, Petro-chemical and Ethanol Production, Ink Coating and Odor Abatement, and many other applications on a global basis.

Thermal oxidizers, also known as fume incinerators or afterburners, are widely used to control air emissions. Many processes, such as paint baking, drying of printing inks and curing of certain polymers, evolve vapors of flammable, toxic solvents. In the baking or curing oven, these solvent vapors pose an explosion or fire hazard, so they are diluted well below their lower limit of flammability by adding large amounts of dilution air.

The rapid evolution of information technology (IT) has made possible the transmission of a wide range of information in a short period of time, resulting in the transformation of society in aspects such as logistics and business styles. During this transformation, quick assessment of the circumstances and prompt actions were also required in the production lines, making real-time collection of field information indispensable.

Downloads

Instruction Manuals

- *Discontinued: CX2000 Installation and Connection Guide (845 KB)

- CX1000/CX2000 S335 (200 KB)

- *Discontinued: DAQSTATION CX2000 Communication Interface (2.7 MB)

- *Discontinued: Daqstation CX2000 CX Operator User's Manual (607 KB)

- CX2000 S30 (186 KB)

- *Discontinued: Daqstation CX2000 (6.8 MB)

- *Discontinued: Daqstation CX2000 Operation Guide (1.4 MB)

- DXA120 DAQSTANDARD DX-P Hardware Configurator (1.4 MB)

- DAQSTATION CX1000/CX2000 Functional Changes Resulting from Firmware Upgrade (Version 3.02) (307 KB)

- DXA120 DAQSTANDARD Hardware Configurator User's Manaul (9.4 MB)

- Daqstation CX1000/CX2000 [SUPPLEMENT] (160 KB)

- DXA120 DAQSTANDARD Viewer User's Manual (2.2 MB)

- Daqstation CX2000 [SUPPLEMENT] (171 KB)

- *Discontinued: Precautions on the Use of the CX2000 (44 KB)

- WX104 DAQEXPLORER User's Manual (6.5 MB)

- *Discontinued: WX201 DataBrowser User's Manual (6.1 MB)

- Proper Disposal of This Product/ How to Replace and/or Dispose the Batteries (559 KB)

- Service Manual: DAQSTATION CX1000/CX2000 (2.2 MB)

General Specifications

Technical Information

- *Discontinued: Control and Measurement Station DAQSTATION CX2000 Product Guide (4.6 MB)

- *Discontinued: DAQSTATION Control Measurement Station CX2000 Ladder Communication with PLC (194 KB)

- *Discontinued: DAQSTATION CX2000 Control and Measurement Station Installation Guidance (1.9 MB)

- SMARTDAC+ CX Replacement Guide (Model and Suffix Code Replacement) (2.2 MB)

Engineering Tools

Looking for more information on our people, technology and solutions?

Contact Us