- Advanced Application Temperature Controller UT75A

- Button Operated DX1000/DX2000

- Mid-level Temperature Controller UT55A/UT52A

- Touch Screen Paperless Recorder GX10/GX20

- Program Controller UP35A/UP32A

- Program Controller UP55A

- US1000 Digital Indicating Controller

- Dual-loop digital indicating controllers UT32A-D

- Entry model digital indicating controller UT32A-V/C/R

- General Purpose Temperature Controller UT35A/UT32A

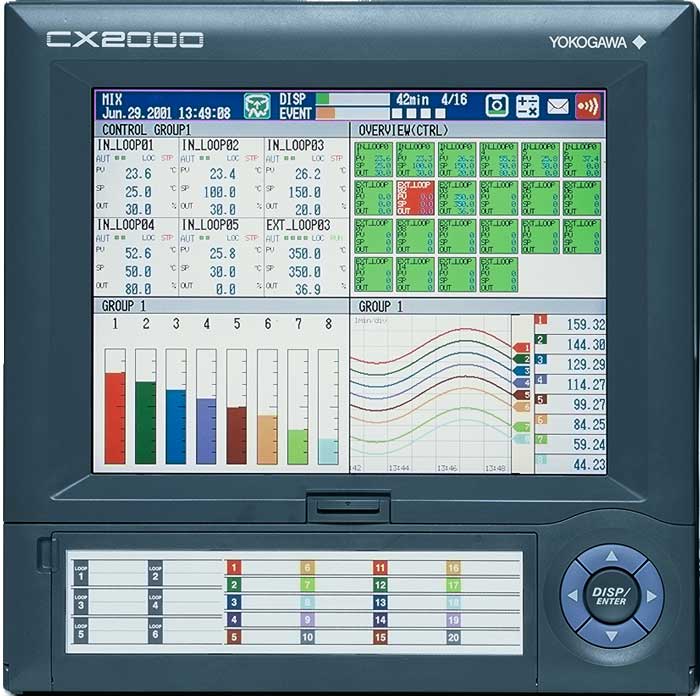

CX defines the next generation in process control by fusing recording, control and networking into a single, compact product. It delivers "Out of the box, ready to go" real-time and historical process monitoring. CX controls your process using internal PID loops and/or external controllers. One or more CXs link your process to the networked world with built-in Ethernet, web server, e-mail and FTP functions.

Resources

The Japan Steel Works, LTD., Muroran Plant uses the Control and Measurement Station CX2000, UP series program controllers, and UT series digital indicating controllers for operation of its heat treating furnaces.

The rapid evolution of information technology (IT) has made possible the transmission of a wide range of information in a short period of time, resulting in the transformation of society in aspects such as logistics and business styles. During this transformation, quick assessment of the circumstances and prompt actions were also required in the production lines, making real-time collection of field information indispensable.

Downloads

Instruction Manuals

- *Discontinued: CX2000 Installation and Connection Guide (845 KB)

- *Discontinued: DAQSTATION CX2000 Communication Interface (2.7 MB)

- *Discontinued: Daqstation CX2000 CX Operator User's Manual (607 KB)

- *Discontinued: Daqstation CX2000 (6.8 MB)

- *Discontinued: Daqstation CX2000 Operation Guide (1.4 MB)

- DXA120 DAQSTANDARD DX-P Hardware Configurator (1.4 MB)

- DXA120 DAQSTANDARD Hardware Configurator User's Manaul (9.4 MB)

- DXA120 DAQSTANDARD Viewer User's Manual (2.2 MB)

- *Discontinued: Precautions on the Use of the CX2000 (44 KB)

- WX104 DAQEXPLORER User's Manual (6.5 MB)

- *Discontinued: WX201 DataBrowser User's Manual (6.1 MB)

General Specifications

Technical Information

- *Discontinued: Control and Measurement Station DAQSTATION CX2000 Product Guide (4.6 MB)

- *Discontinued: DAQSTATION Control Measurement Station CX2000 Ladder Communication with PLC (194 KB)

- *Discontinued: DAQSTATION CX2000 Control and Measurement Station Installation Guidance (1.9 MB)

- SMARTDAC+ CX Replacement Guide (Model and Suffix Code Replacement) (2.2 MB)

Looking for more information on our people, technology and solutions?

Entre em contato conosco