"Early detection of failures in refractory materials"

Customer Concerns

Early detection of failures in refractory materials

Temperatures inside a harsh condition reactor such as synthesis gas reactor that produces carbon monoxide can reach as high as 1,600 degrees Celsius, and the outer surface of the reactor vessel can get as hot as 300 degrees Celsius. To protect their iron walls and enhance combustion efficiency, these facilities are lined on the inside with refractory bricks. As these bricks age and deteriorate, a variety of problems such as a drop in combustion efficiency and breaks in the iron wall can occur and result in the initiation of an emergency shutdown by the plant control system. In addition to being a safety issue, such unplanned shutdowns result in lost production and financial losses.

The Solutions and the Benefits

Quick detection of hot spots

Hot spots on the outer surface of a reactor or furnace occur wherever there are breaks in the refractory brick lining. With its optical fiber sensor cable, the Yokogawa DTSX distributed temperature sensor is able to constantly monitor for changes in the temperature of the outer wall and quickly spot problems early on, before they have a chance to grow into big problems and result in plant shutdowns or worse.

Proper maintenance period according to the conditions

Any reactor or furnace with a refractory brick lining needs to be shut down more frequently than other industrial facilities so that personnel can look inside and check the condition of the bricks. With the DTSX’s ability to monitor surface temperature 24/7/365, maintenance can be performed as soon as any signs are detected that indicate deterioration in the refractory liner. This switch to condition-based maintenance ensures that problems are caught early on and corrected.

How DTSX Works

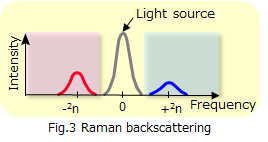

Measuring the intensity of Raman scattered light

Using pulses of laser light beamed through an optical fiber cable, the DTSX is able to detect temperature-dependent variations in signal frequency that are the result of a phenomenon known as Raman scattering that occurs along the entire length of the optical fiber cable, and it also can determine the locations of those temperature readings using light that is bounced back (backscattering) to the source.

Example: Along a 6,000 meter optical fiber cable, nearly 6,000 measurement points

By measuring how long it takes light to make a round trip back to the source (backscattering), the DTSX is able to calculate the location for each temperature reading. Abnormalities can be located with a spatial resolution of just one meter.

Installation of the Optical Fiber Sensor Cable

There is no need to install a large number of temperature sensors. A single length of optical fiber sensor cable can be affixed to the surface of the reactor or furnace using aluminum tape or something similar. Figure 5 shows the layout of the optical fiber sensor cable on a reactor outer wall.

Looking for more information on our people, technology and solutions?

Contact Us相關業種

-

石油和天然氣

石油和天然氣

-

石油和天然氣下游

近年來,石油和天然氣下游產業面臨著越來越多的挑戰。這些挑戰包括待加工原料的特性變化、工業設施及設備的老化、能源成本的上升、缺乏能夠使煉油廠安全有效運行的熟練技術工人,以及市場和客戶的需求不斷變化。

多年來,橫河與許多下游公司合作,致力於提供應對這些挑戰和問題的工業解決方案。橫河的解決方案幫助工廠投資者盡可能實現最大的盈利能力和工廠內可持續的安全。 -

化學工廠

化學工廠依賴連續生產與批次生產流程,兩者對控制系統的需求各不相同。連續流程需要具備高穩定性與可靠性的控制系統,以避免故障導致生產線停機;而批次流程則強調控制系統的彈性,能靈活調整配方、作業程序等。這兩種類型的系統都需能管理產品的可用品質歷史,並執行非常規操作。憑藉完整的產品組合、經驗豐富的系統工程師,以及全球銷售與服務網絡,Yokogawa 能為每一個工廠製程提供解決方案。

相關產品&解決方案

-

DTSX3000 [長距離]

DTSX3000可以用於傳統和非傳統的油/氣井下應用、LNG和煉油廠、管道和油罐泄漏檢測以及其他需要監控溫度的應用。

-

光纖溫度傳感器DTSX

我們採用的技術是使用光纖本身作為溫度傳感器。

由於它可以測量長距離和寬範圍的溫度分布,所以能夠無遺漏地監測沿線溫度。因此,它不只在工廠中有效使用,而且在需要溫度監測的領域也能發揮作用。