"Early detection of failures in refractory materials"

Customer Concerns

Early detection of failures in refractory materials

Temperatures inside a harsh condition reactor such as synthesis gas reactor that produces carbon monoxide can reach as high as 1,600 degrees Celsius, and the outer surface of the reactor vessel can get as hot as 300 degrees Celsius. To protect their iron walls and enhance combustion efficiency, these facilities are lined on the inside with refractory bricks. As these bricks age and deteriorate, a variety of problems such as a drop in combustion efficiency and breaks in the iron wall can occur and result in the initiation of an emergency shutdown by the plant control system. In addition to being a safety issue, such unplanned shutdowns result in lost production and financial losses.

The Solutions and the Benefits

Quick detection of hot spots

Hot spots on the outer surface of a reactor or furnace occur wherever there are breaks in the refractory brick lining. With its optical fiber sensor cable, the Yokogawa DTSX distributed temperature sensor is able to constantly monitor for changes in the temperature of the outer wall and quickly spot problems early on, before they have a chance to grow into big problems and result in plant shutdowns or worse.

Proper maintenance period according to the conditions

Any reactor or furnace with a refractory brick lining needs to be shut down more frequently than other industrial facilities so that personnel can look inside and check the condition of the bricks. With the DTSX’s ability to monitor surface temperature 24/7/365, maintenance can be performed as soon as any signs are detected that indicate deterioration in the refractory liner. This switch to condition-based maintenance ensures that problems are caught early on and corrected.

How DTSX Works

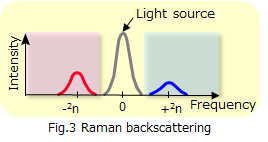

Measuring the intensity of Raman scattered light

Using pulses of laser light beamed through an optical fiber cable, the DTSX is able to detect temperature-dependent variations in signal frequency that are the result of a phenomenon known as Raman scattering that occurs along the entire length of the optical fiber cable, and it also can determine the locations of those temperature readings using light that is bounced back (backscattering) to the source.

Example: Along a 6,000 meter optical fiber cable, nearly 6,000 measurement points

By measuring how long it takes light to make a round trip back to the source (backscattering), the DTSX is able to calculate the location for each temperature reading. Abnormalities can be located with a spatial resolution of just one meter.

Installation of the Optical Fiber Sensor Cable

There is no need to install a large number of temperature sensors. A single length of optical fiber sensor cable can be affixed to the surface of the reactor or furnace using aluminum tape or something similar. Figure 5 shows the layout of the optical fiber sensor cable on a reactor outer wall.

Looking for more information on our people, technology and solutions?

Contact UsRelated Industries

-

Oil & Gas

Yokogawa has a wealth of experience in every part of the oil and gas business, from offshore and onshore facilities to pipelines, terminals, and deepwater operations. We provide solutions that enhance safety, ensure accurate and reliable operation, and increase plant efficiency.

-

Oil & Gas Downstream

The oil & gas downstream industry has been facing an increasing number of challenges in recent years. These include the changing characteristics of the feedstock to be processed, aging of process facilities and equipment, rising cost of energy, lack of skilled plant operators who can run a refinery safely and efficiently, and the ever-changing requirements from both the market and the customer.

Over the years, Yokogawa has partnered with many downstream companies to provide industrial solutions focused on solving these challenges and problems. Yokogawa's VigilantPlant solutions have helped plant owners to achieve maximum profitability and sustainable safety within their plants.

-

Chemical

Chemical plants rely on continuous and batch production processes, each posing different requirements for a control system. A continuous process calls for a robust and stable control system that will not fail and cause the shutdown of a production line, whereas the emphasis with a batch process is on having a control system that allows great flexibility in making adjustments to formulas, procedures, and the like. Both kinds of systems need to be managed in available quality history of product, and to be able to execute non-routine operations. With its extensive product portfolio, experienced systems engineers, and global sales and service network, Yokogawa has a solution for every plant process.

-

Iron & Steel

In the iron and steel industry, it is crucial to improve the quality of not only products but also manufacturing and operation technologies, as well as to address environmental and energy-efficiency issues. Yokogawa helps customers to create the ideal plant and evolves with them for mutual growth.

Related Products & Solutions

-

DTSX1 Fiber Optic Heat Detector

DTSX1 stores the functions required for heat detection in one box. DTSX1 analyzes the temperature data with high accuracy by measuring with fiber optic sensor cable and perform high temperature heat detection.

-

DTSX200 Distributed Temperature Sensor

The DTSX200 is a standard version that is ideal for temperature measurement, for medium-sized areas, and for areas where the distance of fiber optic sensor cables is short. It has excellent environmental resistance because it consumes less power and is less dependent on the temperature measurement environment.

-

DTSX3000 Distributed Temperature Sensor

The DTSX3000 is a distributed temperature sensor developed in response to the demand that “one unit be used to monitor temperature distribution a longer distance and a wider area”. A flagship model that meets the expectations for long-distance temperature measurement and high temperature resolution.

-

Fiber Optic Temperature Sensor DTSX

The DTSX fiber optic temperature sensor, which uses optical fiber for the temperature sensor, quickly detects and locates abnormalities in equipment by monitoring temperatures at production facilities located far away and across wide areas 24 hours a day, without omission. Highly accurate predictive maintenance avoids downtime and ensures stable plant operation.