Introduction

Veneer drying is an important process before plywood manufacturing. Controlling veneer’s moisture content to Optimized value for each wood material is a key to make good adhesion characteristics at next plywood manufacturing process. For this purpose, humidity of the air in dryer is controlled and moisture content of veneer is adjusted.

Expected Benefits

- Increase Energy Efficiency of Veneer Dryer Process

- Reduce Operating Cost

- Improve Yield of Veneer for Plywood Manufacturing

- Improve Quality of Veneer for Plywood Manufacturing

Process Overview

In order to control veneer’s moisture content to optimized value from 6 to 20% for each wood material, humidity of the air in the dryer is measured and controlled from 30 to 40%. Temperature is controlled from 130 to 200 deg. C.

As the results, dry veneer with optimized moisture content is manufactured.

Solution Details

Field Data

Process conditions

| Humidity | 30 to 40 % |

|---|---|

| Temperature | 130 to 200 ℃ |

| Pressure | 20 to 40 mmH2O |

| Dust | Trace wood dust |

Measurement system

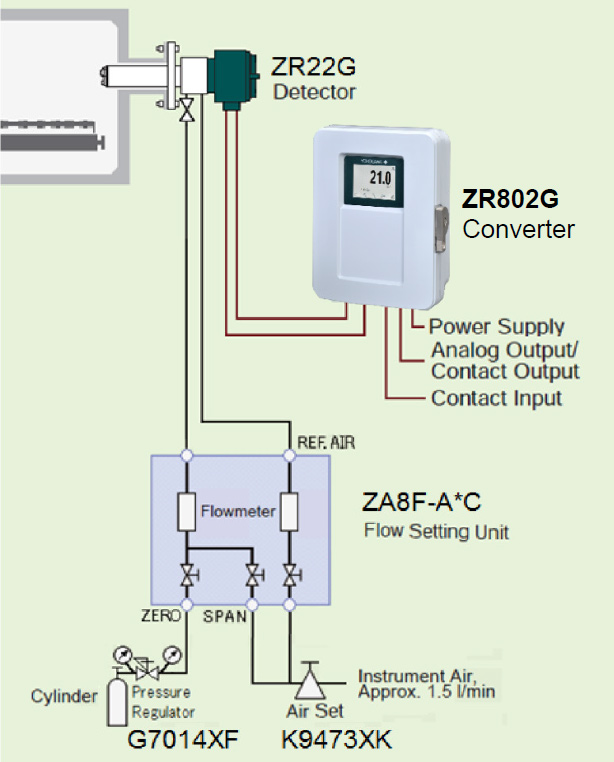

| Detector | ZR22G-040-S-C-E-T-T-E-A /CV |

|---|---|

| Converter | ZR802G-☐-☐-N-N /☐ |

| Flow setting unit | ZA8F-A*C |

| Pressure regulator | G7013XF or G7014XF |

| Air set | K9473XK |

Utilities

| Rated voltage | 100 to 240 V AC |

|---|---|

| Rated frequency | 50/60 Hz |

| Power consumption | 330 VA (Max. 800 VA) |

| Instrument air | 300 to 700 kPa |

相關產品&解決方案

-

氧化鋯式氧氣濃度計 ZR22G、ZR802G

此高溫用氧氣濃度/濕度分析系統由 氧化鋯式氧氣濃度計 ZR22G、ZR802G 組成,其中 ZR22G 偵測器搭載長壽命且高可靠度的氧化鋯感測器,ZR802G 轉換器則具備數位通訊與資料記錄功能。

ZR22G 與 ZR802G 可在無需取樣裝定的情況下,直接且連續量測氧氣濃度與濕度。透過感測器劣化的自我診斷功能(無需使用校正氣體),以及可於現場更換加熱器組件,使維護作業更為簡便,並有效降低營運成本。