Second-generation Ethanol Plant Now Producing Cheap, and Clean-burning Biofuel

Executive Summary

GranBio Investimentos SA is a Brazilian industrial biotech company that was born out of the vision of bringing about a green revolution through the construction of second-generation ethanol plants that will produce cheap, clean-burning biofuel from readily available biomass. Following its establishment in June 2011 by Gran Investimentos S.A., a holding company in which the Gradin family are the primary investors, the company built Bioflex 1, the first commercial second-generation ethanol plant in the Southern Hemisphere. Bioflex 1 started operation in early 2014 and is able to produce 82 million liters of biofuel per annum, making it one of the largest such facilities in the world.

GranBio Investimentos SA is a Brazilian industrial biotech company that was born out of the vision of bringing about a green revolution through the construction of second-generation ethanol plants that will produce cheap, clean-burning biofuel from readily available biomass. Following its establishment in June 2011 by Gran Investimentos S.A., a holding company in which the Gradin family are the primary investors, the company built Bioflex 1, the first commercial second-generation ethanol plant in the Southern Hemisphere. Bioflex 1 started operation in early 2014 and is able to produce 82 million liters of biofuel per annum, making it one of the largest such facilities in the world.

As the main automation contractor (MAC) for the Bioflex 1 project, Yokogawa South America was involved from the front end engineering design (FEED) stage, performing the basic design for a control system and field instrumentation solution that will reduce costs and improve production efficiency throughout the lifecycle of the plant. Yokogawa installed the CENTUM VP integrated production control system; the csTUNER control loop tuning software; the CENTUM VP Batch package to control the plant's pretreatment, enzymatic hydrolysis, fermentation, and distillation/separation units; field instruments including FOUNDATION™ fieldbus-enabled ADMAG AXF magnetic flowmeters, DPharp EJA series pressure/differential pressure transmitters, and control valves; and the Plant Resource Manager (PRM) asset management package. Yokogawa South America was responsible for product delivery, engineering, and operator training.

Overview of second-generation ethanol process

The Challenges and the Solutions

Improving productivity

Second-generation ethanol and other chemical products are produced from non-food agricultural materials and industry waste. The cost of producing biofuel with this method compares favorably to fossil fuels such as oil and natural gas, and it produces fewer greenhouse gases. The GranBio plant produces ethanol from energy cane, bagasse, and straw, all of which are readily available in Alagoas State.

The raw materials used in this production process must first be pretreated to make the cellulose in the plant cell walls easier to break down with enzymes (hydrolysis) and solubilize hemicellulose sugars. The cellulose in the plant cell walls is in a matrix with other polymers, primarily hemicellulose and lignin, and the pretreatment of biomass with heat removes these polymers from the cellulose core. During the cooking process, great care must be taken to keep the biomass at a steady temperature. The pretreated cellulose fragments are then broken down using enzyme preparations to obtain double glucose molecules, which are then split into single glucose residues. In a fermentation reactor, these residues are converted to ethanol using microbes.

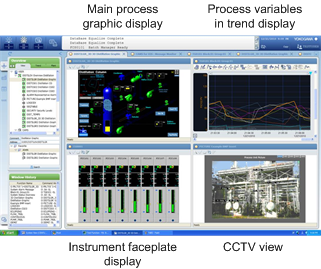

"All in one" high density HMI display

Based on whichever raw materials are being processed, the pretreatment and fermentation settings have to be automatically selected and executed. All important parameters for these processes are preconfigured in the CENTUM VP Batch package. When an operator selects a recipe from the package menu, all of the preconfigured settings are automatically selected and downloaded to the individual controllers so that each sequence can be automatically started. At a human machine interface (HMI) terminal, an operator can monitor the status of the reactions in ergonomically designed process graphic display, trend display, alarm summary display, and control display windows. When each batch operation is completed, the operation data are compiled for an automatically generated batch report (provided as a standard function). In these ways, the CENTUM VP Batch package improves productivity at GranBio.

Reduction of operator workload and safe operation

FieldMate parameter setting

PRM device status and diagnostic data

Many different field devices, including magnetic flowmeters, DPharp EJA series pressure/differential pressure transmitters, and control valves, are installed at this plant, and it has nearly 2,000 I/Os. Some of the devices are exposed to high temperature processes and other harsh conditions and/or are mounted in high, narrow, and other difficult to access locations.

With the PRM asset management package, the health of these devices can be monitored from the central control room (CCR), eliminating the need for difficult and time consuming physical inspections. The PRM device navigation window displays the status of plant-wide assets with a Windows Explorer-like interface, enabling maintenance engineers to quickly identify devices that require online diagnosis. This is an especially valuable time-saving tool during plant start-up, when engineers and operators must check many loops and control valves. The centralization of the management of these plant assets ensures that maintenance information gets immediately to the right persons, depending on the type and criticality of the diagnostic data analysis. This changes the maintenance engineer workflow and enables a more proactive maintenance approach.

Other valuable tools provided by Yokogawa include FieldMate, which can be used from the CCR to set field device parameters, and csTUNER, which simplifies the task of tuning PID loops. With its ability to optimize tuning parameters and generate a tuning report, csTUNER is particularly useful during the plant start-up and commissioning phases, reducing the workload of both engineers and operators.

The use of these tools helps to ensure that GranBio's operators and engineers are able to comfortably operate and keep this plant safe 24/7.

Customer Satisfaction

Manoel Carnauba, a GranBio vice president, comments as follows:

"Brazil is a dominant player in the bioethanol market. The biofuel market is steadily growing, and second-generation biofuel is attracting attention as an environmentally friendly energy source. We appreciate Yokogawa's modern and highly reliable control system and field instruments, and value their engineering capabilities, and believe we made the right decision to rely on them as the MAC for the construction of this large-scale commercial second-generation ethanol plant. As we were able to complete the basic specifications at an early stage and maintain consistency with all the specifications, this reduced the total cost of the control system and the instrumentation. We completed our project on schedule and on budget."

Plant view

Shift operators in central control room

相关行业

-

生物燃料

为了阻止全球变暖的趋势,生物燃料的生产和需求呈上升趋势。在化工、石油及其他工业领域中,横河电机拥有良好的测量和控制解决方案,并且已经开发出用于生物乙醇和其他可再生燃料领域的技术,可确保生产过程的可靠性和高效性。

-

化工

化工厂依靠连续和批量的生产过程,每个生产过程对控制系统都有不同的要求。连续的过程需要一个强大而稳定的控制系统,该系统不能因为自身失效而导致生产线关闭;批量过程的要点在于拥有一个可以灵活调整地公式和程序的控制系统。两种系统都需要在产品质量记录中进行管理,并且能够执行非常规操作。横河电机凭借广泛的产品组合、经验丰富的系统工程师、广泛的销售和服务网络,为工厂流程提供解决方案。

相关产品&解决方案

-

EJA110A

Traditional-mount Differential Pressure Transmitter based on the EJA-A Series.

-

EJA110E

Standard Traditional-mount Differential Pressure Transmitter based on the EJA-E Series.

-

EJA115

Differential Pressure Transmitter attached to an IFO assembly based on the EJA-A Series.

-

EJA115E

Standard Differential Pressure Transmitter attached to an IFO assembly based on the EJA-E Series.

-

EJA118

Differential Pressure Transmitter with Remote Diaphragm Seals based on the EJA-A Series.

-

EJA118E

Standard Differential Pressure Transmitter with Remote Diaphragm Seals based on the EJA-E Series.

-

EJA120A

Traditional-mount Differential Pressure Transmitter designed for Draft Range applications based on the EJA-A Series.

-

EJA120E

Standard Traditional-mount Differential Pressure Transmitter designed for Draft Range applications based on the EJA-E Series.

-

EJA130A

Traditional-mount High-static Differential Pressure Transmitter based on the EJA-A Series.

-

EJA130E

Standard Traditional-mount High Static Differential Pressure Transmitter based on the EJA-E Series.

-

EJA210A / EJA220A

Flanged-mounted Differential Pressure Transmitter designed for Liquid-level applications based on the EJA-A Series.

-

EJA210E

Standard Flange-mounted Differential Pressure Transmitter designed for Liquid-level applications based on the EJA-E series.

-

工厂资源管理系统(PRM)

工厂资源管理系统(PRM)是横河电机用于资产管理的一个关键平台。该平台旨在改进操作和维护,通过获得更大的可预测性,使工厂资产的可靠性和可用性增强。

-

移动现场设备管理(FieldMate)

FieldMate 3.0是一款基于PC的工具,可以使用户在整个维护工作流程中对智能化的现场设备“一目了然、先知先觉、慎思密行”。

-

集散控制系统(DCS)

横河电机的集散控制系统(DCS) 可实现工业过程的自动化和控制,并提高业务绩效。30,000多套系统的经营者选择采用横河电机的DCS来实现其生产目标。