Introduction

Veneer drying is an important process before plywood manufacturing. Controlling veneer’s moisture content to Optimized value for each wood material is a key to make good adhesion characteristics at next plywood manufacturing process. For this purpose, humidity of the air in dryer is controlled and moisture content of veneer is adjusted.

Expected Benefits

- Increase Energy Efficiency of Veneer Dryer Process

- Reduce Operating Cost

- Improve Yield of Veneer for Plywood Manufacturing

- Improve Quality of Veneer for Plywood Manufacturing

Process Overview

In order to control veneer’s moisture content to optimized value from 6 to 20% for each wood material, humidity of the air in the dryer is measured and controlled from 30 to 40%. Temperature is controlled from 130 to 200 deg. C.

As the results, dry veneer with optimized moisture content is manufactured.

Solution Details

Field Data

Process conditions

| Humidity | 30 to 40 % |

|---|---|

| Temperature | 130 to 200 ℃ |

| Pressure | 20 to 40 mmH2O |

| Dust | Trace wood dust |

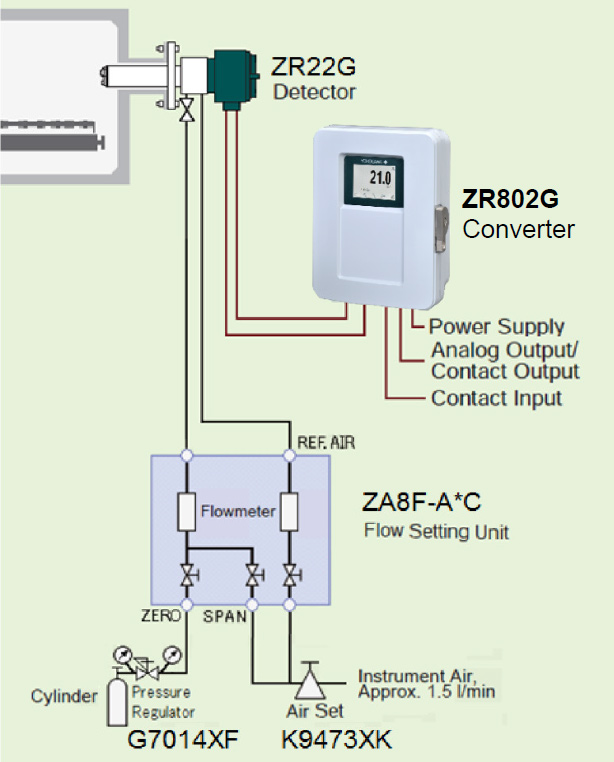

Measurement system

| Detector | ZR22G-040-S-C-E-T-T-E-A /CV |

|---|---|

| Converter | ZR802G-☐-☐-N-N /☐ |

| Flow setting unit | ZA8F-A*C |

| Pressure regulator | G7013XF or G7014XF |

| Air set | K9473XK |

Utilities

| Rated voltage | 100 to 240 V AC |

|---|---|

| Rated frequency | 50/60 Hz |

| Power consumption | 330 VA (Max. 800 VA) |

| Instrument air | 300 to 700 kPa |

相关产品&解决方案

-

氧化锆氧/湿度分析仪ZR22G、ZR802G

该氧浓度和湿度分析仪可在高温下使用,由ZR22G检测器和ZR802G转换器组成。ZR22G检测器配备寿命长且高度可靠的氧化锆传感器,ZR802G转换器配备数字通信和数据记录功能。

ZR22G 和 ZR802G无需采样设备即可直接连续测量。通过传感器劣化的自诊断(不使用校准气体)、现场更换加热器组件,易于维护并降低运营成本。