In the agitation process of a chemical plant, raw materials (liquids and powders) supplied by pumps are mixed using an agitator to produce products through chemical reactions. If the supply pump deteriorates and the material supply is unstable, unexpected changes may occur in the production recipe, impacting product quality. Additionally, if the supply of raw materials is stopped, the agitator to run idle, potentially shut-down production due to damage to the motor bearings or couplings.

By appropriately monitoring the condition of supply pumps, deterioration and breakdowns can be prevented, however, it is difficult to monitor a large number of supply pumps deployed in a wide plant with the operator rounds.

Customer Issues

Equipment monitoring with limited man-hours

A chemical plant utilizes a large number of supply pumps, making it difficult to monitor them through operator rounds. Instead of relying on operator rounds carried out by workers, there is a need to automate constant monitoring.

Impact on production quality due to deterioration of supply pumps

To stabilize product quality, it is necessary to detect signs of abnormality in the supply pumps, and perform appropriate maintenance.

Industrial IoT Wireless Solution Sushi Sensor

Online monitoring

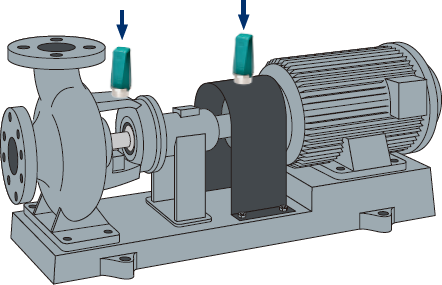

The condition of equipment can be monitored online by utilizing the Sushi Sensor. Wireless vibration sensors are installed on the center of shaft coupling between the motor and supply pump. The condition of the bearings is constantly monitored to detect signs of equipment abnormality (“something wrong”)

Maintaining and improving inspection quality

The collected data can be monitored and recorded using the Data Logging Software GA10 through the LoRaWAN® network. By digitizing the condition of equipment and enabling quantitative judgments based on the collected data, the monitoring system prevents the overlooking of signs of abnormalities. In utilizing GA10's Anomaly Detection Function, the AI detects changes in equipment conditions as signs of abnormality and alerts the user of such signs.

Benefits

By replacing operator rounds of equipment monitoring with the Sushi Sensor, equipment with a high risk of failure can be efficiently identified.

In one case at a chemical plant, the wireless vibration sensor is installed on multiple supply pumps to monitor the condition of equipment online, stabilizing to improved product quality. As a result of the detailed diagnosis of the equipment that exceeded the threshold, bearing wear was detected in the motor, and maintenance was carried out. This enabled the equipment to maintain its health condition and prevented product quality from being impacted. Currently, the temperature of raw material storage tanks, piping and containers are also being monitored by Sushi Sensor, expanding the scope of monitored processes and equipment.

By installing the Sushi Sensor, the entire plant is monitored online to contributes to maintaining the health of equipment and stabilizing product quality.

Example of System Configuration

相关行业

-

化工

化工厂存在连续生产与批次生产两种流程,两者对控制系统需求各异。连续工艺要求控制系统具备高稳定性与可靠性,避免因故障导致生产线停机;而批次工艺则强调灵活调整配方、工序等参数的能力。两类系统均需实现产品质量追溯管理,并支持非常规操作执行。横河电机凭借丰富的产品组合、资深系统工程师团队及全球销售服务网络,可为不同工艺流程提供定制化解决方案。

相关产品&解决方案

-

Sushi Sensor工业物联网无线解决方案

Sushi Sensor是一种用于工业物联网(IIoT)的无线解决方案。它具有良好的抗环境性能,采用广域无线通信方法LoRaWAN®,可实现节电及远距离通信。

-

数据记录软件GA10

通过GA10软件可以建立一个无需编程的数据采集系统。GA10能够通过Modbus通信获取数据,与横河的记录器、数据记录仪、温度控制器和功率监视器实现兼容。