"Early detection of failures in refractory materials"

Customer Concerns

Early detection of failures in refractory materials

Temperatures inside a harsh condition reactor such as synthesis gas reactor that produces carbon monoxide can reach as high as 1,600 degrees Celsius, and the outer surface of the reactor vessel can get as hot as 300 degrees Celsius. To protect their iron walls and enhance combustion efficiency, these facilities are lined on the inside with refractory bricks. As these bricks age and deteriorate, a variety of problems such as a drop in combustion efficiency and breaks in the iron wall can occur and result in the initiation of an emergency shutdown by the plant control system. In addition to being a safety issue, such unplanned shutdowns result in lost production and financial losses.

The Solutions and the Benefits

Quick detection of hot spots

Hot spots on the outer surface of a reactor or furnace occur wherever there are breaks in the refractory brick lining. With its optical fiber sensor cable, the Yokogawa DTSX distributed temperature sensor is able to constantly monitor for changes in the temperature of the outer wall and quickly spot problems early on, before they have a chance to grow into big problems and result in plant shutdowns or worse.

Proper maintenance period according to the conditions

Any reactor or furnace with a refractory brick lining needs to be shut down more frequently than other industrial facilities so that personnel can look inside and check the condition of the bricks. With the DTSX’s ability to monitor surface temperature 24/7/365, maintenance can be performed as soon as any signs are detected that indicate deterioration in the refractory liner. This switch to condition-based maintenance ensures that problems are caught early on and corrected.

How DTSX Works

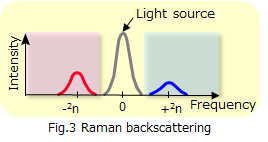

Measuring the intensity of Raman scattered light

Using pulses of laser light beamed through an optical fiber cable, the DTSX is able to detect temperature-dependent variations in signal frequency that are the result of a phenomenon known as Raman scattering that occurs along the entire length of the optical fiber cable, and it also can determine the locations of those temperature readings using light that is bounced back (backscattering) to the source.

Example: Along a 6,000 meter optical fiber cable, nearly 6,000 measurement points

By measuring how long it takes light to make a round trip back to the source (backscattering), the DTSX is able to calculate the location for each temperature reading. Abnormalities can be located with a spatial resolution of just one meter.

Installation of the Optical Fiber Sensor Cable

There is no need to install a large number of temperature sensors. A single length of optical fiber sensor cable can be affixed to the surface of the reactor or furnace using aluminum tape or something similar. Figure 5 shows the layout of the optical fiber sensor cable on a reactor outer wall.

Looking for more information on our people, technology and solutions?

Contact Us相关行业

-

石油和天然气

横河电机在石油天然气行业的各个环节均拥有丰富经验,业务覆盖海上与陆上设施、管道运输、终端处理及深水作业等领域。我们提供的解决方案能够提升安全水平、确保设备准确可靠地运行,并有效提高工厂运营效率。

-

油气下游

近年来,石油天然气下游行业正面临日益增多的挑战。这些挑战包括:需处理的原料特性不断变化、工艺设施与设备逐渐老化、能源成本持续攀升、能够安全高效运营炼油厂的熟练操作人员紧缺,以及市场和客户需求的快速变化。

多年来,横河电机与众多下游企业携手合作,提供专注于解决这些挑战与难题的工业解决方案。横河电机的 VigilantPlant解决方案助力工厂业主实现工厂内的更大盈利和可持续安全运营。

-

化工

化工厂存在连续生产与批次生产两种流程,两者对控制系统需求各异。连续工艺要求控制系统具备高稳定性与可靠性,避免因故障导致生产线停机;而批次工艺则强调灵活调整配方、工序等参数的能力。两类系统均需实现产品质量追溯管理,并支持非常规操作执行。横河电机凭借丰富的产品组合、资深系统工程师团队及全球销售服务网络,可为不同工艺流程提供定制化解决方案。

相关产品&解决方案

-

DTSX200 分布式温度传感器

DTSX200是一种标准版本,非常适合对中型区域,以及光纤传感器电缆距离较短的区域进行温度测量。它具有优异的耐环境性,因为它消耗的功率更小,对温度测量环境的依赖更小。

-

DTSX3000 [长距离]

DTSX3000可以用于传统和非传统的油/气井下应用、LNG和炼油厂、管道和油罐泄漏检测以及其他需要监控温度的应用。

-

DTSX™1光纤热检测器

DTSX1将热检测所需要的功能存储在一个盒子中。DTSX1通过光纤传感器电缆进行测量,并执行高温热检测,从而以高精度分析温度数据。

-

光纤温度传感器DTSX

我们采用的技术是使用光纤本身作为温度传感器。

由于它可以测量长距离和宽范围的温度分布,所以能够无遗漏地监测沿线温度。因此,它不只在工厂中有效使用,而且在需要温度监测的领域也能发挥作用。