廢棄物處理正成為都市日益嚴峻的挑戰。廢棄物發電 (WTE) 技術提供環保的解決方案,同時滿足能源需求。全球已有超過 150 座 WTE 和焚化設施採用橫河電機控制系統,其技術是邁向更清潔、更高效世界的關鍵。

2022 年,來自丹麥、在 WTE 工廠優化方面具備卓越專業知識的公司 Dublix Technology 加入橫河電機集團。與 Dublix 合作,我們將提供更全面的增值解決方案。

介紹影片 ⇊

挑戰

客戶挑戰

每個客戶根據電廠類型、燃料種類及所在國法規等因素,都面臨不同的運轉與維護最佳化挑戰。

解決方案

依據客戶需求及可行性研究,廢棄物發電與生質能領域的專家提供工程化解決方案,以提升電廠運轉效率與維護管理。

關鍵技術

CENTUM VP 整合控制系統確保電廠「持續運轉」不間斷,提升可再生能源領域的生產力與獲利能力。

Collaborative Information Server (CI Server)

Yokogawa CI Server 透過數位轉型及降低運維工作,立即提升生產效率,並構建企業級數位轉型框架。

客戶挑戰

鍋爐結渣與鍋爐污垢是維護管理中最常見的困擾之一。

解決方案

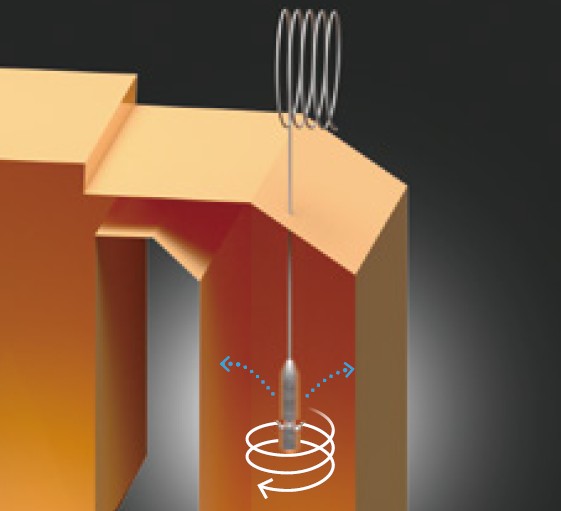

Yokogawa 與 Dublix Technology 提供 JetClean 線上鍋爐清洗系統,透過旋轉噴嘴噴射水柱,在焚化爐滿載運轉時清潔鍋爐。水蒸氣膨脹形成的壓力波能有效去除鍋爐表面污垢。此系統可提升爐體效率,降低非運轉維護頻率。同時,JetClean 可使鍋爐出口煙氣溫度降低約 60 ℃,減少鍋爐腐蝕。

關鍵技術

Dublix Technology 的 JetClean 是專為廢棄物發電及生質能燃燒鍋爐設計的線上清洗系統,安裝於歐洲與亞洲超過 40 座廢棄物發電廠。

Collaborative Information Server (CI Server)

Yokogawa CI Server 透過數位轉型與降低運維工作,立即提升生產效率,並構建企業級數位轉型框架。

Yokogawa ZR 系列分析儀適用於燃燒監控與控制,可協助各行業優化燃燒效率並降低 NOX 排放。

TruePeak TDLS 氣體分析儀採專利峰面積積分法,非常適合在嚴苛製程環境中進行原位分析,顯著提升鍋爐運轉效率。

客戶挑戰

將焚化爐實際裝載的廢棄物量與計畫負載之間的差異降至最低。實際裝載量會因廢棄物的種類與狀態而異。

解決方案

Yokogawa CENTUM 分散控制系統(DCS)的操作介面站(HIS)顯示趨勢圖,其中曲線標示焚化爐的計畫負載與實際累積重量。如果出現與計畫負載的偏差,操作人員可以調整鏈條爐排速度以進行修正。

關鍵技術

CENTUM VP 整合控制系統可確保不中斷的「全時運轉」,以在再生能源領域達到最佳生產效率與收益。

Collaborative Information Server (CI Server)

Yokogawa CI Server 透過數位化轉型與運維簡化,立即提升生產效率,同時建立數位轉型框架。

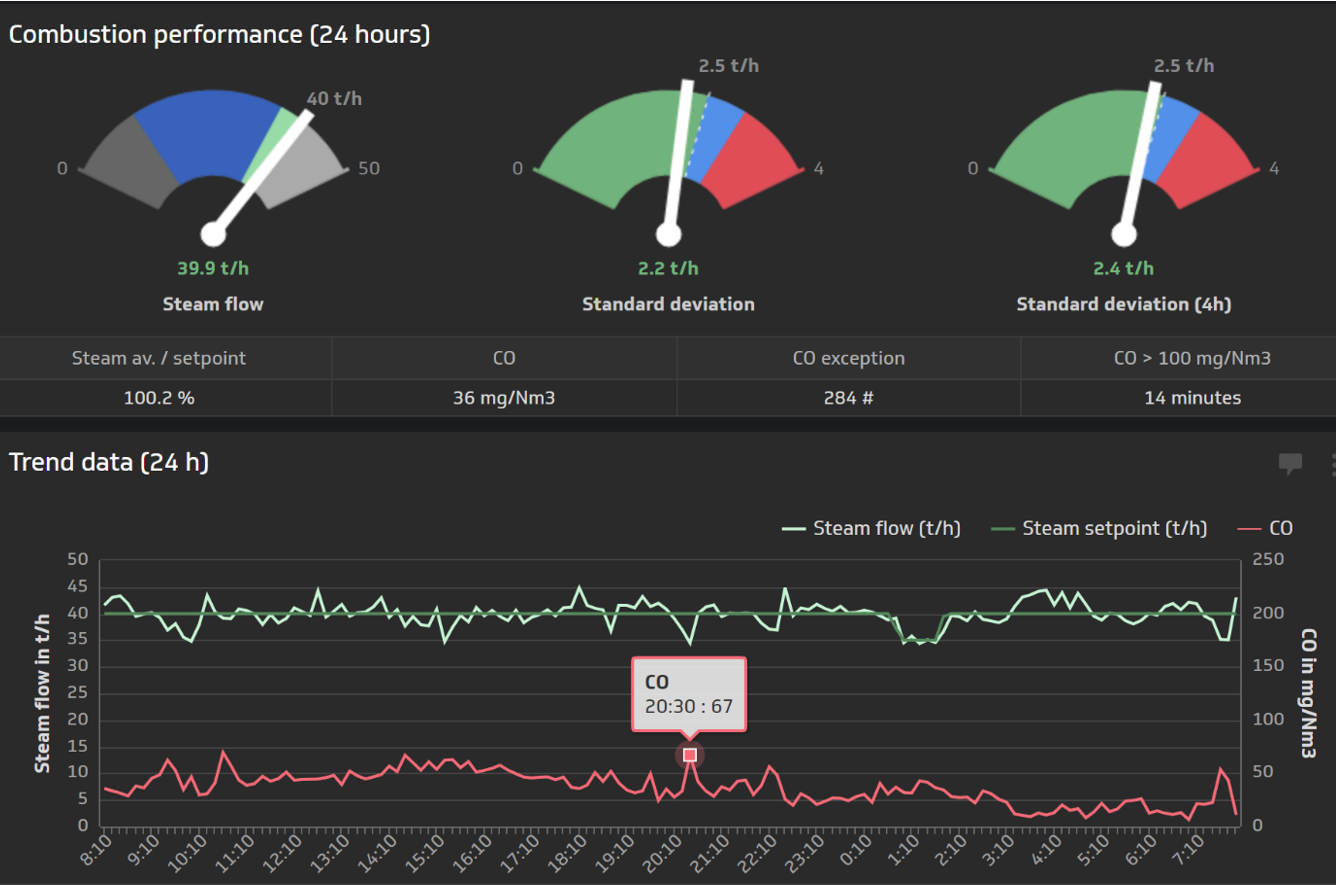

Dublix Technology 的 CombustIQ 為先進燃燒控制軟體,運用專有預測技術與專家製程知識。它分析歷史數據與操作程序,以確保廠區全天候高效運行。透過穩定蒸汽供應並優化其使用,CombustIQ 提升發電效率、減少非計畫停機、增加燃燒能力並提高收益,同時降低不完全燃燒造成的 NOx 及其他有害排放。

Details

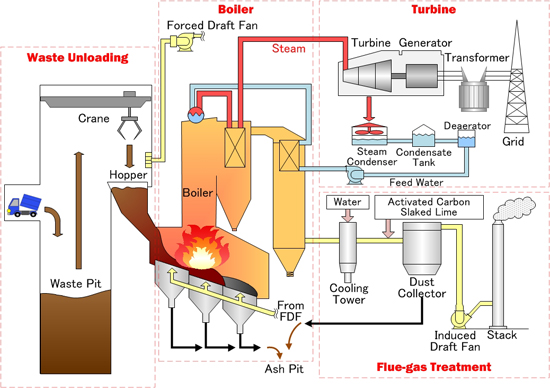

廢棄物送至焚化設施後,先被倒入儲坑,然後由起重機輸送至焚化爐。廢棄物燃燒後,殘留的灰燼收集於焚化爐底部。燃燒熱可用於區域供熱系統、游泳池用熱水系統及其他應用,也可加熱鍋爐產生蒸汽。蒸汽驅動渦輪機發電。排放氣體經冷卻塔與集塵器處理後,透過煙囪排出。

控制與測量技術

| 廠區系統與儀器設備 | ||

|---|---|---|

|

資訊

|

控制

|

測量

|

| 製程 | ||

| 廢棄物卸料 | 鍋爐 | 渦輪機 |

|

|

|

| 煙氣處理 | ||

|

||

參考

- A robust and reliable integrated control and safety system (ICSS) made up of the CENTUM CS3000 PCS and the ProSafe-RS SIS ensures safe operations while fully automating key processes.

- A variety of analytical instruments accurately measure the concentrations of key components, and this data can be monitored and controlled by the Yokogawa PCS.

新聞

-

新聞 | 企業 2025年10月31日 橫河電機收購 Intellisync 與 WiSNAM,強化資安與電網管理解決方案

- 建立再生能源與減碳的數位樞紐 -

-

新聞 | 專案 2023年10月24日 橫河電機在波蘭大型垃圾焚燒發電廠安裝高性能燃燒控制解決方案

- 產能滿載運轉,每年可增加5,500噸垃圾焚燒量 -

-

新聞 | 企業 2022年5月25日 Yokogawa收購丹麥Dublix公司

-提高廢棄物能源化(WTE)和生質燃料發電廠效率的解決方案供應商-

-

新聞 | 專案 2014年10月7日 橫河電機贏得英國康沃爾郡垃圾焚燒發電廠的控制系統訂單

想了解更多技術&解決方案嗎?

聯絡我們