PRM软件集中管理来自自动化和生产资产的大量状态和维护信息。PRM具有多种维护支持功能,包括用于监控和诊断设备仪表的在线功能。

介绍视频

本视频展示PRM软件如何有效预防突发设备故障,避免影响工厂生产。

新版PRM R4.07功能升级摘要(2023年12月)

- PST调度程序增强

新注册的PST定位器可用于PST调度程序的手动测试。 - PROFINET通信网络上的HART设备支持

PRM R4.07支持通过PROFINET/HART转换器接入PROFINET网络的HART设备。 - 支持Windows 10企业版LTSC 2021及Windows Server 2022标准版

PRM概览

为什么建立完善的资产管理制度对于实现可靠、高效、盈利的工厂运营至关重要

工厂设备损坏或故障可能对整个运营产生重大影响。横河电机的工厂资源管理系统(PRM)帮助优化设备维护计划,并控制维护成本。

工厂设备维护面临的挑战

- 庞大设备群的复杂性

- 维护资源不足

- 技术经验流失

横河电机的高效设施维护方法

- 集中管理并可视化工厂设备数据

- 通过提升维护效率实现降本增效

横河电机提供既可靠又高效的设备维护解决方案

横河电机是值得信赖的系统供应商,既能保障工厂持续运行,又能提供维护解决方案,确保生产运营不间断的同时实现可靠性与效率双提升。

横河电机三重工厂管理优化体系

根据工厂需求选择切入点

工厂设备与装置故障会导致生产流程运转异常与状态波动,进而延长故障原因排查及系统恢复所需时间,最终造成整体生产效率下降。通过对设备进行故障预判并对工厂流程实施预防性维护监控,让您能在不影响连续生产的前提下实现设备热插拔,降低对运营的影响。

横河电机提供跨三层的解决方案:

- 设备状态可视化与远程配置

- 设备模板功能实现多设备参数统配

- 设备类型管理器(DTM)及专业校准工具助力设备快速投入运行

- 通过追踪、比对参数日志实现更高效的设备更换

- 远程完成设备参数检查配置,显著节省工时

- 设备与设备性能监控

- 设备巡检通过周期轮询状态数据,实现对设备状况的高效评估

- 通用型诊断算法可兼容测量来自不同厂商的阀门

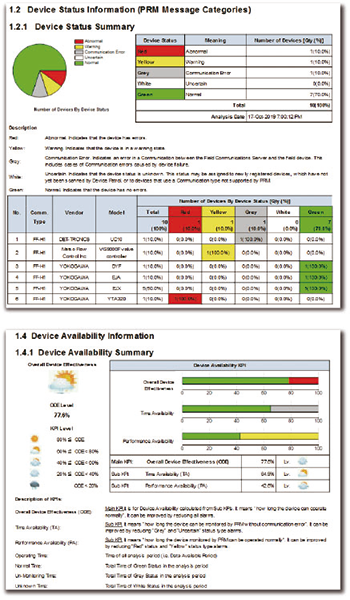

- 定期自动生成的设备状态报告(现场资产KPI报告)可视化运行状态,全面评估工厂整体健康状态

- 增强维护与运营的数据支撑

- 关键设备信息不仅可通过DCS随时查阅,更能通过综合ICSS集成系统(*1)即时获取,助力快速响应问题处理

- 回路诊断功能可提升控制阀性能并维持高生产效率

- 通过对接上层系统(ERP/CMMS(*2)等),实现工单处理效率优化

*1) ICSS:集成控制与安全系统(含DCS、SIS等子系统)

*2) ERP:企业资源规划,CMMS:计算机化维护管理系统

PRM系统架构

详细介绍

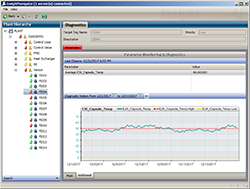

资产诊断

1.诊断功能

控制阀是工厂中至关重要的设备之一。突发故障可能导致产品质量下降甚至工厂停产。工厂现场设备数量庞大,为了维持正常功能,在制定和执行阀门巡检维护计划时,许多客户面临挑战。控制阀诊断技术能有效解决这一问题,其内置的五种基于现场设备数字技术的诊断逻辑表达式,可准确检测阀门劣化趋势。该诊断方案支持多厂商设备,能够运用同一套诊断逻辑完成全厂所有阀门的评估。基于诊断结果,可制定并优化巡检维护计划的优先级排序。

- 依据劣化状态与设备重要性,轻松制定巡检维护计划

- 支持多厂商设备,实现全厂设备统一评估

- 工程操作简便:仅需选择配置文件即可完成参数设置

随着HART、PROFIBUS、FOUNDATION™现场总线及无线通信等具备数字通信功能的现场设备普及,远程配置与精细监控得以实现,显著提升工作效率。此外,现场设备自诊断功能可实时检测异常。然而,设备中诸多参数信息尚未得到充分利用。监控这些参数能有效把握设备异常趋势,并采取预防性维护措施。

- 依据劣化状态与设备重要性,轻松制定巡检维护计划

- 预防设备突发故障,保障可靠运行

- 工程操作简便:仅需选择配置文件即可完成参数设置

2. 泵气蚀的预测性维护(气蚀检测系统)

提供优化维护与运营的关键数据

设备异常的早期检测助力工厂高效维护

横河电机的气蚀检测系统无须依赖传统振动异响检测方式——该方式只能在气蚀现象加剧后被动识别。我们的解决方案通过捕捉早期气蚀引发的流体压差,实现气蚀程度的量化评估。气蚀早期预警为工厂操作人员争取宝贵时间,使其能制定应对策略,避免管道受损风险。

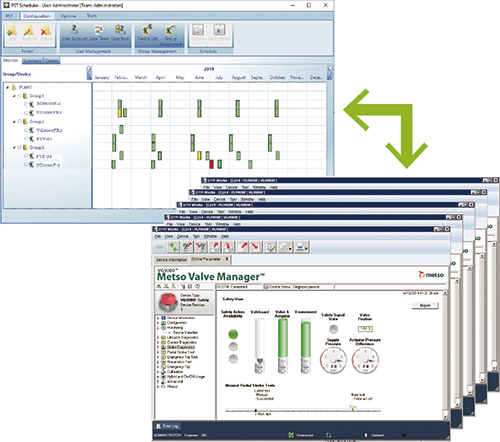

3. PST调度程序

PRM和PST调度程序

部分行程测试(PST)可延长紧急切断阀的全行程测试(FST)间隔周期,降低维护成本。PST调度程序为PST流程带来准确性、高效性与集成性。该系统可调度自动/半自动/手动PST,并自动记录连接至横河电机ProSafe-RS或第三方安全仪表系统的阀门测试结果,全面兼容多个厂商的安全阀。

按预设配置执行多阀门自动/半自动PST测试并记录结果。PST显著延长FST间隔周期,传统FST需停产执行。

依托PRM平台运行,PST调度程序远程执行安全阀厂商的PST程序并记录结果。测试过程规划完善且高效,测试结果单界面集中展示,无需额外软硬件支持。横河电机的PRM及PST调度程序支持多厂商安全阀的统一管理。

PST调度程序的特点

- 调度:周、月、年、按需

- 模式:手动、半自动、自动

- 执行:串行、并行

- 操作:执行、暂停、恢复、跳过

- 记录:PST结果

提高安全系统性能

横河电机的ProSafe-RS安全仪表系统即使在单模块配置下也通过了SIL3认证。按固定计划执行PST(部分行程测试)是确保安全系统在紧急情况下能够正确运行的关键。ProSafe-RS与PRM(工厂资源管理系统)结合PST调度程序,不仅简化了安全设备的管理,更提高安全系统性能。此外,管理安全设备无需额外的布线或硬件(如多路复用器)。

阀门选择的灵活性

Vigilant集成合作伙伴(VIP)计划是一个开放的、非排他性的、基于标准的、以互操作性为导向的倡议。它使横河电机ProSafe-RS安全仪表系统(SIS)和PRM资产管理系统的用户能够使用来自德莱赛梅索尼兰(Dresser Masoneilan)、福斯公司(Flowserve Corporation)、美卓(Metso)和萨姆森公司(SAMSON AG)的先进现场设备。

什么是部分行程测试(PST)?

部分行程测试(PST)是指在装置运行期间,部分开启和关闭紧急关断(ESD)阀门。安全标准(如IEC 61508、IEC 61511或ANSI/ISA-84.00.01)要求对这些ESD阀门进行全行程测试(FST),并根据安全完整性等级(SIL)在特定时间间隔内进行,以确保其在紧急情况下功能正常。FST要求这些关断阀门完全打开和关闭,并且只能在装置停车维护时进行。然而,通过执行PST,可以延长FST的间隔时间,从而延长装置运行时间,并降低运营支出(OPEX)和总拥有成本(TCO)。

4. 现场总线诊断

FieldConnex®高级诊断模块(ADM)

除支持使用示波器和数据历史记录软件等强大工具外,ADM还拥有独特的调试向导,可将关键工厂启动阶段所需的时间减少多达80%。

除支持使用示波器和数据历史记录软件等强大工具外,ADM还拥有独特的调试向导,可将关键工厂启动阶段所需的时间减少多达80%。

ADM的在线监测功能通过PRM的用户界面提供可操作信息,在FF总线物理层问题变得严重之前指示其变化。

集成FieldConnex ADM接口,可扩展PRM资产管理能力的范围,使其涵盖基金会现场总线(FOUNDATION™ Fieldbus)网段的通信状态。

优势

最终用户和工厂操作员:

- 减少安装时间

- 加快调试速度

- 提高装置运行时间

- 简化防爆验证

工程公司:

- 简化规划

- 消除不必要的工程工作

- 记录完整的网段信息用于工厂移交

维护团队:

- 实现预见性维护方法

- 降低停机频率

- 提高装置运行时间

CMMS*接口

PRM具有与Maximo的CMMS接口,Maximo是IBM Software公司的企业资产管理系统(EAM)。当两个系统连接时,Maximo可通过从PRM获取实时设备信息来提供更优的维护操作。

*CMMS:计算机化维护管理系统

在线监控

1. 导航功能

管理全厂资产的单一窗口

设备导航器采用类Windows资源管理器界面,显示全厂资产的状态。灵活的导航机制使维护人员能够快速识别需要在线诊断的工厂区域。现场设备的直观状态图标会根据诊断条件改变颜色。维护人员可以轻松聚焦于需要关注的特定工厂区域和资产。

在正确的时间将正确的信息传递给正确的人

根据诊断数据分析的类型和关键程度,维护信息会立即传送给相应的人员(操作员和/或维护人员),从而可以在正确的时间采取必要措施,提高生产效率。

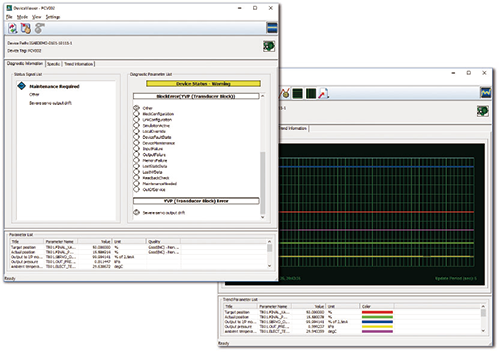

设备查看器

设备诊断数据以直观的格式在线显示。设备数据趋势可一目了然地进行监控。

工厂设备状况可以整体以列表或资源管理器格式查看。可提供多种显示格式以适应工厂需求。在线监控现场设备状态,图标设计便于快速概览。

设备查看器可显示横河电机及其他供应商的FOUNDATION™现场总线和HART设备的实时诊断与趋势数据。其特色是采用彩色高亮显示设备状态和参数,帮助操作员一目了然地掌握设备状态,无需亲临现场。设备查看器也可在CENTUM VP操作站上运行,使操作员能够确定故障是由工艺过程还是现场设备引起的。

2. 远程调整

您可以直接在工厂资源管理器(PRM)界面上远程设置与调整设备参数。通过供应商提供的设备类型管理器(DTM)配置工具,能够针对不同型号设备调用直观易懂的图形化界面进行可视化操作。对于阀门定位器等调试复杂的设备,还可调用专用PRM插件应用程序实现高效阀门调试。这些工具的应用既缩短了设备恢复时长,也提升了设备维护效率。

3. 设备参数高效设置

R4.01版新增设备参数模板功能。通过该功能完成参数设置后,可将模板批量下载至多台设备。便捷的参数重置操作,使新增设备得以即刻启用。

4. 资产信息管理

通过分析历史报警记录制定巡检计划。设备保存参数及其他装置参数均可复用于巡检校验场景,支持按设备类型、报警类别等维度分类管理,有效规避报警遗漏及巡检后模式切换遗忘等问题。

与FieldMate™的同步

FieldMate™是多功能现场设备管理向导,用于参数设置、调整及故障诊断。所有通过FieldMate™执行的调整设置,均可通过PRM(工厂资源管理器)窗口进行监控管理。

5. 维护报警

维护报警功能采集设备预警信号和先期诊断数据,添加相关信息后通知维护人员。面向操作员的报警信息则通过CENTUM HIS(人机界面站)的指导消息传递。

操作员指南

预测性维护报警生成的指导消息,可在设备故障时为操作员提供充足的工艺调整时间。操作员可通过点击操作指导消息,启动设备查看器,来查看设备诊断信息。

维护人员指南

PRM操作指导消息能帮助维护人员根据报警详情和可能原因确定所需采取的措施。这使得现场维护人员能够高效地利用时间。DeviceViewer窗口会显示现场设备的实时诊断参数和趋势数据。

维护标记

维护标记是维护工程师用于标识设备状态的工具。您可为每台设备分配维护标记,维护工程师通过这些标记可设置和检查设备的工作状态。维护标记还可与CENTUM系统的操作标记关联,实现维护工程师与操作员之间的信息共享及作业协同。

6. 良好协作

与其他公司的协作

PRM具备开放的集成工具,可与第三方厂商的阀门管理及设备维护软件连接。通过插件应用(PIA)接口,这些程序可作为PRM客户端运行,并通过横河电机主机系统与相关设备通信。横河电机向签约软件供应商提供PIA接口开发套件。供应商基于此接口开发程序后,需提交横河电机进行集成测试。

支持Dresser阀门定位器的ValVue系统

兼容Fisher DVC5000f/DVC5000、DVC6000f/DVC6000阀门定位器的ValveLink系统

与GE Energy的System 1®的集成

现场设备和机械的维护成本占工厂总维护成本的51%。

现场设备和机械的维护成本占工厂总维护成本的51%。

GE Energy的System 1是一套成熟的软件平台,可实现设备与关键流程的实时优化、状态监测及故障诊断。

通过与System 1集成,PRM不仅能监控压力变送器、流量计等现场仪表,还可通过统一界面诊断涡轮机、旋转设备及往复式设备。

效益

- 优化维护策略,实现效能增加

- 通过提升设备性能、安全性和运营表现,降低运行风险

- 基于准确规划避免非计划停机与重大故障,有效控制成本

- 减少人工数据采集需求,实现成本节约

- 确保设备在设计参数内运行,预防设备损伤

KPI报告

现场设备采集数据生成的现场资产KPI报告,可直观呈现设备及周边工艺的潜在异常趋势。基于这些报告,可针对设备当前及未来工况制定准确的维护方案。

R4.01版本新增全厂设备量化状态显示功能,并支持生成现场资产关键绩效指标报告(现场资产KPI报告)。这些KPI指标可作为制定维护计划的重要参考依据。

设备报告功能

横河电机InsightSuiteAE服务用户可通过PRM系统,基于FOUNDATION™ Fieldbus和HART设备存储的报警与事件信息,生成日/周/月/年度现场资产KPI报告。该报告不仅能全面评估设备运行状态,更能帮助维护人员优化维保优先级。

互操作性

- 设备文件 (合作伙伴门户)

- 支持设备

- 设备文件介质清单(合作伙伴门户)

- HIST认证设备(横河电机网站)

- FIST认证设备(横河电机网站)

- PRM集成

- PRM插件应用集成(横河电机网站)

- PST调度程序集成(横河电机网站)

- 配件

- PRM兼容配件(合作伙伴门户)

查看合作伙伴门户需注册会员。

1. 设备文件目录

本设备文件目录仅供合作伙伴门户成员使用。请点击上方链接注册会员后查阅。

- 设备文件(合作伙伴门户)

2. 支持设备

新版PRM支持的设备清单可通过合作伙伴门户获取。请完成注册以查看详细信息。

- 设备文件介质中包含的设备列表(合作伙伴门户)

横河电机采用获得FOUNDATION™现场总线认证的HIST(主机互操作性支持测试)方案,已验证横河电机FOUNDATION™现场总线设备与第三方设备在横河电机主机系统中的互操作性。通过HIST测试的设备详见以下清单。

- HIST认证设备列表(链接至横河电机中国网站)

FDT/DTM互操作性支持测试(FDT指现场设备工具,DTM指设备类型管理器)是一项旨在增强横河电机FDT框架应用与第三方现场设备DTM之间兼容性的测试活动。虽然DTM与框架应用各自独立开发,但必须符合指定的FDT接口规范。只有在确保接口兼容性的前提下,两者才能实现正常交互。尽管FDT组织已通过认证流程对DTM进行验证,横河电机仍额外设立了“互操作性测试实验室”,专门用于验证第三方DTM与我们框架应用(包括PRM和FieldMate)的兼容性。

- FIST认证设备列表(链接至横河电机中国网站)

3. PRM集成

PRM采用开放式集成架构,通过插件应用接口(PIA)实现与阀门管理系统等第三方软件的对接。该接口允许外部应用程序作为PRM客户端运行,并通过横河电机主机系统与现场设备进行通信。横河电机为签约合作伙伴提供PIA开发套件,供应商需基于该套件开发接口软件,并提交横河电机进行系统集成测试。

- PRM插件应用集成说明(链接至横河电机中国官网)

PRM集成的PST调度程序可远程执行紧急切断阀的部分行程测试(PST)。以下为通过PST调度程序集成测试的定位器及设备类型管理器(DTM)清单。

- PST调度程序集成(链接至横河电机中国官网)

4. 配件

PRM支持以下型号作为HART通信接口,可通过多路复用器获取HART设备的参数及诊断信息。

- PRM兼容配件清单(合作伙伴门户)

参考

- 生物制药工厂使用CENTUM,VP Batch,Exaquantum和PRM。

- 大型生物科技生产设施的整体系统集成。

- Operational Excellence by Asset Maximization, Utilizing Yokogawa's DCS, SIS, Analyzers, and Field Instruments.

- The CENTUM VP PCS and ProSafe-RS SIS were integrated using the same engineering environment.

- Nearly 60 gas chromatographs and a large number of other types of analyzers in several analyzer houses.

- Reinstrumentation project at HDPE plant replaced legacy pneumatic instruments and PLCs with integrated CENTUM CS 3000 PCS and ProSafe-RS SIS.

- HART field devices can be monitored from the central control room with the plant resource manager (PRM) package, enabling a more predictive and proactive maintenance approach that reduces total cost of ownership.

CENTUM VP was selected for the BOP in a concentrated solar power plant of the Xina Solar One Project.

Yokogawa provided a complete control system solution that integrates the subsystems in the plant as a system of systems.

- Xstrata designed and supplied a plant wide process control system for the project based on a Yokogawa CENTUM CS 3000 system.

- Xstrata has used Yokogawa extensively in the past and trusted the reliability of the CS 3000 system.

- FDT technology gives users centralized access to all devices.

- FDT technology provides a common environment for configuring, operating, or maintaining any devices.

- Fieldbus technology introduced to realize predictive and preventive maintenance.

- ISAE to improve the reliability of diagnosis and parameter setting, utilizing data collected by PRM.

- CS Batch is used to automate a wide range of Reichhold's batch processes and multi-product/multi-path processes.

- Using PRM, process engineers can immediately find out the status of every field device without having to do an onsite inspection.

- Integration of CENTUM CS 3000 with ProSafe-RS improves plant safety and reliability.

- Yokogawa's PRM package manages more than 500 HART field devices including control valves.

Thai Acrylic Fibre Co., Ltd. (TAF) was established in 1987 and is currently a leading acrylic fiber manufacturer in the ASEAN region with 450 employees. It produces a wide range of acrylic fiber productions with varied deniers and the annual production recorded 77,000 megatons in 2004 which is five times the production rate at the time of establishment.

- PRM allows a preventive maintenance approach where maintenance can be scheduled and performed before a field device fails.

- Exaquantum gathers plant data from the CENTUM VP to generate a variety of reports on the polymerization process.

- Smooth and safe switchover to the new system

- Easy-to-use, easy-to-engineer system, plus various post-installation enhancements

- Tuned controllers for smooth plant operation and better traceability of process upsets

- Various other improvements thanks to advanced process control and MVC implementation

Saudi Aramco's operations span the globe and the energy industry. The world leader in crude oil production, Saudi Aramco also owns and operates an extensive network of refining and distribution facilities, and is responsible for gas processing and transportation installations that fuel Saudi Arabia's industrial sector. An array of international subsidiaries and joint ventures deliver crude oil and refined products to customers worldwide.

PetroChina Guangxi Petrochemical Company has completed construction of a combined refinery and petrochemical production complex in Qinzhou, a port city in China's Guangxi Autonomous Region. With a 10 million ton per year capacity, the refinery is one of China's largest, and is truly world class, using a highly advanced hydrogenation process, with the main process technologies coming from the USA and France.

- Yokogawa's CENTUM VP and PRM improve efficiency at new nylon plant in Thailand.

- At the plant startup stage, PRM was used together with FieldMate to thoroughly check all loops.

- Yokogawa's integrated solution contributed to reliable and efficient operation.

- All the instrument information is fully integrated with the instrument management system.

为了对工厂实现集中控制,子系统都与横河的CENTUM VP DCS集成。

- Kuraray EVAL和横河为CENTUM系统的扩展和现代化做了精心准备。

- 横河PRM工厂资源管理系统对400多台现场总线仪表的管理也有助于项目顺利进行。

Process automation end users are under more pressure than ever to do more with less. The current economic climate means that many automation capital projects are on hold. With capital budgets tighter than ever, users instead focus on operational budgets (where cost cutting is also a key concern), or on automation investments with a very rapid return on investment.

In today's dynamic industrial marketplace, the only constant is change. Raw material costs, energy costs, market demands, environmental and safety regulations, technology, and even the nature of the labor force itself are constantly changing, and not always in predictable directions.

Yokogawa Electric Corporation promotes the standardization of FOUNDATION™ fieldbus as the communication foundation supporting Asset Excellence for VigilantPlant, which is an approach aimed at the advancement of plant instruments and equipment. With the recent dramatic advancement of fieldbus technologies, information processing technologies, and network speed, it has become possible to process various kinds of information inside the field sensors and transmit the results to the distributed control system (DCS) and host computer.

Intelligent field instruments and process analyzers accumulate diverse field information including process values and diagnostic results. This data needs to be sent to upper systems such as distributed control systems (DCS) via digital communications such as FOUNDATION Fieldbus and analyzer buses, or hybrid communications such as HART and Brain, and visualized to enable the customer to utilize them for plant operations and maintenance.

As field instrumentation devices become increasingly digitized and computerized, interactive and remote access to a large quantity of field information becomes possible. This will increase the efficiency of plant equipment maintenance by reducing labor requirements in field patrol work for example.

There has been increasing demand for cost reductions and lower-priced products in the manufacturing industry, and maintaining cost competitiveness and achieving optimum costs have become necessary for the survival of manufacturers. This calls for minimizing TCO (Total Cost of Ownership) over the whole life cycle of plants and maximizing TVO (Total Value of Ownership).

Environment and safety are major topics on a global scale in recent times. As symbolized by the effectuation of the Kyoto Protocol, an interest in preserving the environment is growing worldwide, and there is also a tendency to criticize more severely, occurrences of industrial accidents that are accompanied by environmental contamination or which may cause damage, etc., to residents in the surrounding areas.

The FieldMate versatile device management wizard is PC software mainly used for configuring and adjusting field devices. Under the concept of "one tool for all," Yokogawa has been enhancing this software to support a wide range of field devices and field communication protocols.

Asset Excellence (AE) provides a set of solutions for maintaining a plant in good condition at reasonable cost to ensure that it works as a production infrastructure. To reduce maintenance costs without causing a risk to production, it is necessary to change from breakdown maintenance to predictive or preventive maintenance.

Latest field devices have not only various self-diagnosis functions but also process-interface-diagnosis functions such as valve diagnosis of valve positioners and impulse line blockage detection of differential pressure transmitters. The YVP valve positioner can easily perform initial tuning, parameter adjustment, trend monitoring, and valve diagnosis, by using the ValveNavi YVP management software.

March 2006

The new CSPC (CNOOC and Shell Petrochemicals Company Limited) petrochemical complex at Daya Bay in southern China is one of the world's largest process industry projects (see box, Figure 1 and Table). It has a control system to match. Process Worldwide spoke to Johan Veerman, principal instrument and process control engineer at CSPC, about the challenges of managing such a huge job.

May 2006

Predictive maintenance allows to schedule plant maintenance before a failure occurs only when it is necessary, greatly reducing unnecessary inspection and improving productivity. Yokogawa's Asset Excellence initiative helps its customers make their plant asset condition predictable and performance sustainable.

2011

Decades of operation, modernization and expansion have left many chemical plants with a somewhat haphazard automation mix of different controls, process control systems, remote I/Os and field devices. The various components may use different communication protocols such as HART, PROFIBUS or FOUNDATION Fieldbus, and are often based on different device integration technologies.

Combining smart instruments, analyzers and valves with a modern asset management system can provide faster response to incidents, enable proactive maintenance, and reduce downtime.

September 2007

Yokogawa's web-based DCS Anywhere has simplified commissioning at the Nanhai petrochemicals complex. With a total investment of 4.2 billion US dollars, the Nanhai petrochemicals complex at Daya Bay in Huizhou, China, has attracted a lot of attention because of its sheer scale.

Offshore, February 2013

Offshore and deep-water production has been a significant factor in the sustained growth of the oil and gas industries over the past decade and this trend is expected to continue beyond 2013.

October 2008

Yokogawa's Raju Seshadri reveals the latest trends in predictive maintenance solutions. We all dream of being able to see into the future, of being able to predict what will happen before it has, and taking decisive action before something negative occurs later.

September 2006

Asset management systems need to be able to handle more data and present information in better formats if plant managers are to move towards proactive maintenance, says John van der Geer, industrial automation marketing manager at Yokogawa Europe.

July 2010

Martin te Lintelo, Yokogawa Europe B.V., The Netherlands, discusses high level control system design for LNG receiving terminals. As demand for LNG increases worldwide, players face seemingly conflicting challenges. On one hand, they must expand capacity in different regions, make the business and production as agile and adaptive as possible, and improve operational efficiency.

下载

视频

What's the proper plant asset management (PAM) to prevent sudden equipment failures? Have the facility managed properly for high-reliable and stable plant operation? Yokogawa's PRM leads to the revolving of PAM issues throughout the plant life cycle.

By prompt trouble shooting realizes to improves Plant Productivity. Yokogawa’s Plant Resource Manager, PRM enables you to check remotely the status of equipment without head on-site. PRM contributes to Increased Plant Productivity.

"Remote plant maintenance is absolutely impossible!" ...Don't you think so?

In order to minimize travel and contact with people, it's becoming commonplace to work remotely. That’s why we’d like to propose the Field Asset KPI Reports provided by Yokogawa PRM.

Yokogawa's Control Valve Diagnostics leads to the revolving of the valve issues throughout the plant life cycle.

Yokogawa's parameter monitoring is effective in understanding the trend of device abnormalities in field devices, and can be used for preventive maintenance of devices.

Yokogawa's InsightSuiteAE leads to the revolving of the plant assets issues throughout the plant life cycle.

Plant Healthcare Service for field assets is a service that Yokogawa quantitatively grasps the status and risks of customer’s plant assets, and provides useful information for asset maintenance optimization.

新闻

-

新闻 | 解决方案&产品相关 2022年1月12日 横河电机升级OpreX控制和安全系统,加强网络安全对策

-

新闻 | 解决方案&产品相关 2020年10月15日 横河电机发布工厂资源管理系统(PRM)R4.04

- OpreX资产管理和诊断的增强解决方案,通过控制阀的异常状态预测支持预测性工厂维护 -

-

新闻 | 解决方案&产品相关 2020年7月1日 横河电机发布PRM调试支持软件包R1.02,这是OpreX资产管理和全系列的解决方案

- 通过使用现场数字技术提高工厂设备调试和定期维护的效率 -

-

新闻 | 解决方案&产品相关 2019年11月14日 横河发布OpreX资产管理和诊断产品系列软件包工厂资源管理系统(PRM)R4.03

- 增强工厂预测维护中的设备诊断功能 -

-

新闻 | 解决方案&产品相关 2018年4月12日 横河电机发布工厂资源管理软件(PRM) 新版本R4.01

- 用于显示工厂设备状态统计信息的维护和操作支持功能 -

想要了解更多的信息,技术&解决方案?

联系我们