挑战

客户面临的挑战

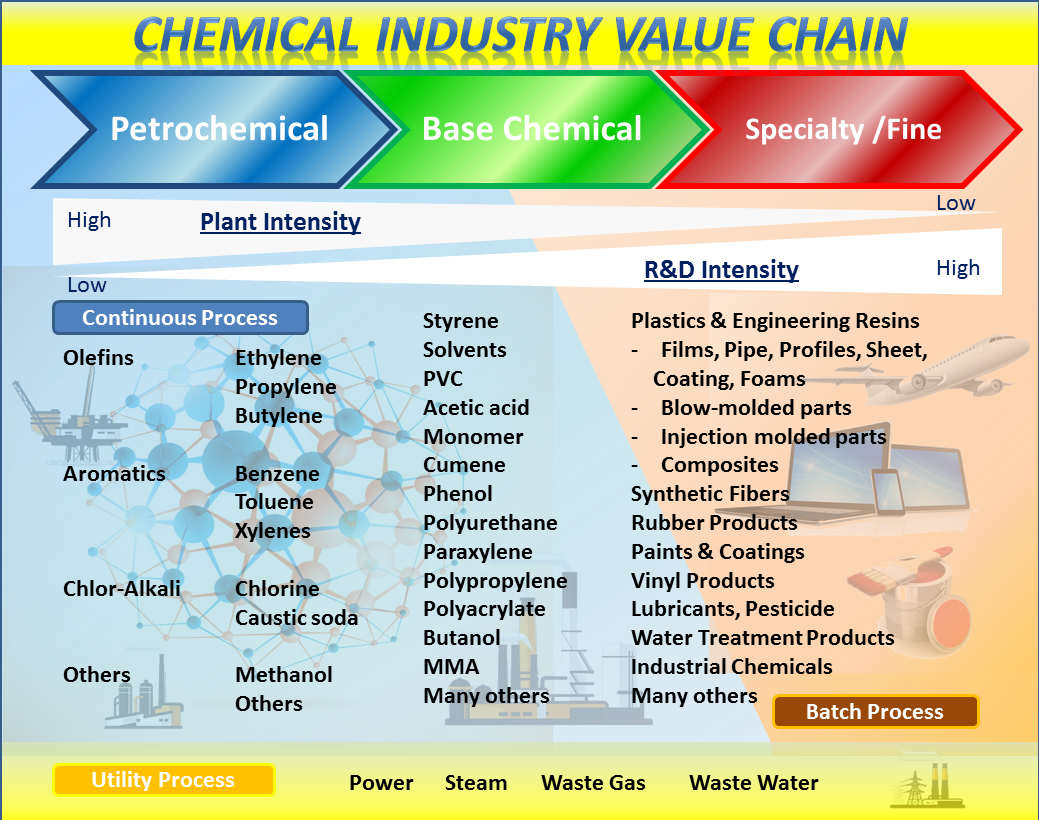

化工行业高度专业化,工厂利用原材料生产中间产品,这些中间产品又被其他工厂用作生产更高级产品的原料。每家化工企业都需要仔细考量其在高度竞争市场中的定位。

我们的解决方案

基础化学品通常采用连续生产工艺,需要高度可靠且稳健的控制系统。在这方面,CENTUM VP集成生产控制系统是理想的解决方案。它能根据工艺要求,实现舒适的操作环境,并通过稳定的过程控制提供顺畅的运行体验。Exapilot在线导航工具为操作员可靠执行停车、开车等非常规操作提供强有力的支持。

赋能技术

生产控制系统:CENTUM VP

集成控制与安全系统(ICSS)的单一数据库简化了工程设计。由于图形、报警窗口和系统状态屏幕都具有相同的外观和观感,操作也更加简便。

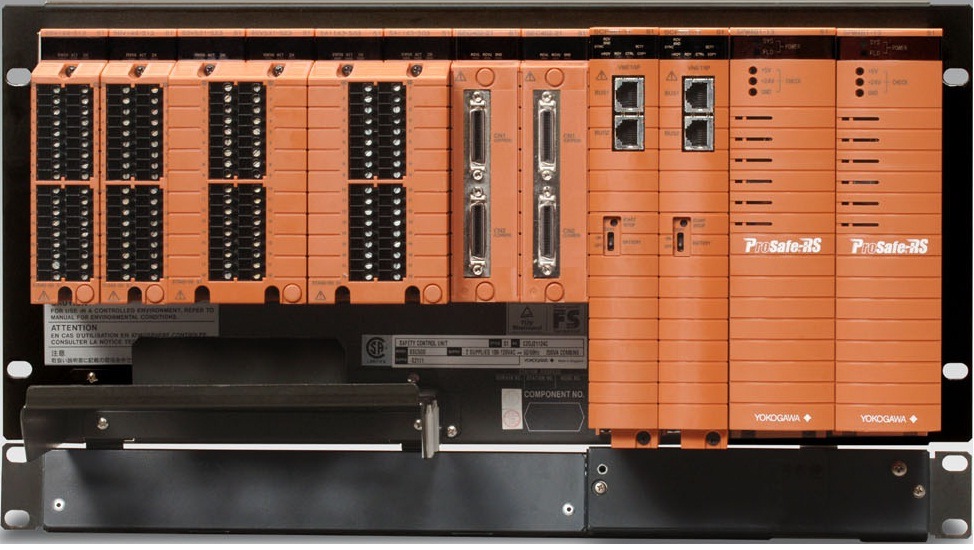

安全仪表系统:ProSafe-RS

横河电机提供多系列的安全仪表系统,从固态型、硬接线型到完全集成的DCS-SIS集成型,涵盖化工行业所需的各种安全完整性等级(SIL 1-4)。

操作效率提升:Exapilot

Exapilot是一款在线导航工具,可指导操作员按步骤执行工厂操作程序。

使用Exapilot,可以标准化形式创建标准操作程序(SOP)。SOP能减少或消除人为错误,从而提高效率并降低总体拥有成本。

分析仪

高响应性的分析系统有助于准确测量产品/中间体的特性,帮助化工企业满足更严格的质量控制和环保法规要求。

现场仪表

“即装即忘”型数字现场仪表提供稳定、准确的过程测量,具有安装成本低、几乎零维护和智能自诊断的特点。作为过程自动化行业及相关技术的供应商,横河电机推出了支持FOUNDATION fieldbus™的设备,并自此开发了完整的FOUNDATION fieldbus™、HART和Profibus协议仪表系列,以及符合ISA100.11a标准的无线通信产品。

参考

Caustic soda and hydrochloric acid, produced in electrolyzer plants, are fundamental materials used in varieties of industries; chemicals, pharmaceuticals, petrol-chemicals, pulp and papers, etc. Profit is the result of the effective production with minimized running / maintenance cost. Proper control of the process brings you stabilized quality of products with the vast operational profit.

Many different types of gases are consumed in industries as varied as chemicals, food & beverages, and medical. These gases are normally delivered in liquid form by trucks and dispensed at the customer site. Although the flow volume of cryogenic liquefied gas is used for billing purposes, it is not easy to accurately measure this because the gas is always at saturation temperatures.

The ammonia (NH3) gas is injected to remove the NOx and thus reduce the NOx concentration in the stack flue gas. With conventional NH3 analyzers that perform measurements indirectly, NH3 concentrations are obtained through a sampling system. Therefore, there are problems with the maintenance and running costs of the sampling system, and time delays in measurement. The TDLS8000 Laser Analyzer is the solution to all these problems.

This paper discusses real industrial examples in which the sitewide utilities system of refinery and petrochemical Sites are optimized with a real time, on line, industrially proven software. Experiences gained during more than 20 years of industrial projects deployed worldwide are commented (Refs. 1 to 10 are related to some recent projects). Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper.

Big and complex industrial facilities like Refineries and Petrochemicals are becoming increasingly aware that power systems need to be optimally managed because any energy reduction that Operations accomplish in the producing Units could eventually be wasted if the overall power system cost is not properly managed. However, process engineers always attempted to develop some kind of tools, many times spreadsheet based, to improve the way utilities systems were operated. The main drawback of the earlier attempts was the lack of data: engineers spent the whole day at phone or visiting the control rooms to gather information from the Distributed Control System (DCS) data historian, process it at the spreadsheet and produce recommendations that, when ready to be applied, were outdated and not any more applicable.

The energy systems, the steps for the implementation of Visual MESA and several features of the model are described in this article, with a focus on the use of the software for the calculation of energy-related KPIs. The EMS implementation project is discussed and the main conclusions relative to the reduction in operating costs are also presented.

Rohm and Haas Company is one of the world's largest manufacturers of specialty materials, including adhesives, sealants, coatings, monomers, electronic materials, inorganic and specialty solutions, and ion exchange resins. Founded in 1909 by two German entrepreneurs, Rohm and Haas has grown to approximately $6 billion in annual revenues.

This paper shows how to improve distillation operations by focusing on procedure automation. It will review the importance of using procedures in distillation operations and highlights the collaboration work underway between Fractionation Research Inc. (FRI) and Yokogawa Corporation to improve procedural operations.

The worlds of process automation and production management have been converging for some time. What once used to be islands of automation and production management functionality connected through highly proprietary integration schemes that were costly to maintain have developed into integrated platforms that provide seamless data exchange between the world of automation and the plant floor, the functions of production and operations management, and integration with business level systems.

July 2011

Process plants are run according to operational procedures. These procedures consist of a set of tasks that are executed in a consistent manner to achieve a specific objective, such as starting up, shutting down or transitioning a unit as part of making a product.

下载

宣传彩页

想要了解更多信息、技术&解决方案?

联系我们