Executive Summary

Rayong Olefins Co., Ltd (ROC). is a subsidiary of SCG Chemicals and is a major producer of ethylene and propylene supplied to downstream manufacturers.

ROC successfully migrated its legacy safety instrumented system to Yokogawa ProSafe-RS, integrating seamlessly with existing CENTUM VP distributed control system and plant asset management. Following positive operational experience with the functionality of Yokogawa Systems, ROC recognized the strategic need to modernize its plant. The additional support for HART protocol enables real-time access to advanced diagnostics from safety field devices.

By migrating from Triconex TriStation 1131 to Yokogawa ProSafe-RS, ROC achieved a future-ready solution that not only addressed their immediate technical and operational challenges, but also positioned them for long-term sustainability.

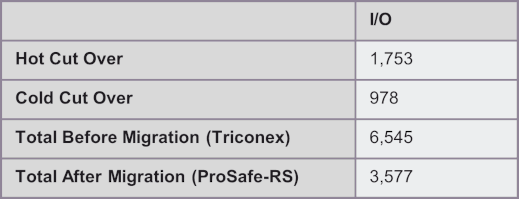

The main objective in the migration was to do both online hot and cold cut over from the legacy Triconex system to ProSafe-RS. The plant was successfully migrated to the latest ProSafe-RS in less than 50 days with almost 50% reduction in safety I/Os.

The Challenges

The existing safety system Triconex, implemented in 1995, was built on traditional DOS-based engineering technology. This legacy platform had posed a significant hurdle during the migration, as a complete re-engineering effort was required to transition to ProSafe-RS architecture.

In additional to the challenges posed by the technological obsolescence, the project was further constrained by a demanding project schedule – the two-month factory acceptance test (FAT). During this critical phase, the engineering team was required to achieve seamless integration between the newly deployed ProSafe-RS and the existing CENTUM VP. Furthermore, it was essential to preserve system integrity and ensure a smooth transition for plant operators.

The Solutions and Benefits

Despite the complexity, the migration was completely successfully, delivering several strategic and operational advantages:

Optimized system size

Through careful system re-engineering, the overall safety I/O count was significantly reduced by almost 50% without compromising functionality. This optimization not only streamlined hardware requirements but also improved system efficiency, reduced installation complexity, and lowered maintenance efforts - resulting in cost savings over the system’s lifecycle.

Enhanced availability and reliability

The new safety system design incorporated additional voted signals, enhancing fault tolerance and overall robustness.

Modular, standardized programming

Legacy safety functions were preserved while the new modular and standardized programming will simplify future maintenance and modifications.

Cybersecurity compliance

Project design included key cybersecurity considerations, ensuring compliance with modern standards.

Comprehensive application testing

The complete integration with CENTUM VP was thoroughly validated including both existing and newly developed diagnostic graphics and alarm functionalities. The extensive testing and tailored technical training sessions equipped operators and engineers with the necessary knowledge and skills to effectively operate and maintain the new safety system.

Customer Satisfaction

The project was executed with high level of efficiency. Project management was exemplary with the project milestones delivered on schedule and adhered to a clearly defined scope. The engineering team demonstrated strong technical competency and a thorough understanding of the system, contributing significantly to the smooth and successful commissioning with minimal disruption to existing operations. After-sales support has been responsive and satisfactory. Timely assistance and effective problem resolution reinforced our confidence in the long-term support and reliability of Yokogawa’s service team.

Overall, the execution and support provided throughout the project exceeded our expectations.

Related Industries

-

석유화학

석유화학 업종 고객사의 요구는 매우 다양합니다. 경쟁이 치열한 오늘날의 시장에서 앞서 나간다면, 생산자는 품질과 생산성을 향상시키기 위해 노력하고 있습니다. Yokogawa는 이 분야에서의 오랜 기간의 광범위한 경험을 바탕으로 이러한 요구에 맞는 맞춤 솔루션을 제공합니다.

Related Products & Solutions

-

Safety Instrumented System (SIS)

안전 계장 시스템(SIS)은 사람, 환경, 자산을 보호합니다. Yokogawa의 SIS와 관련 안전 솔루션은 비상 정지(Emergency Shutdown), 화재 및 가스(Fire & Gas), 버너 관리(Burner Management), HIPPS(고압 보호 시스템) 등의 다양한 애플리케이션에서 널리 사용되고 있습니다.