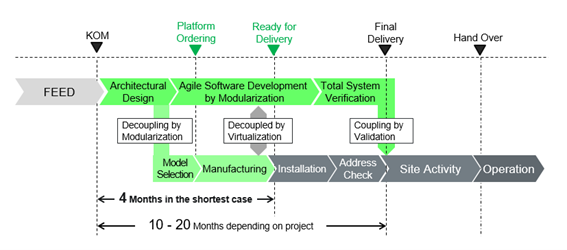

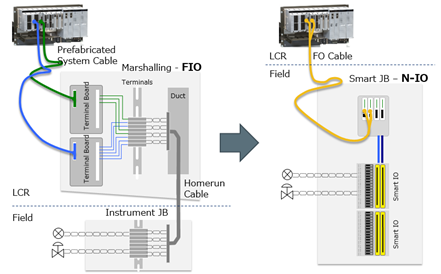

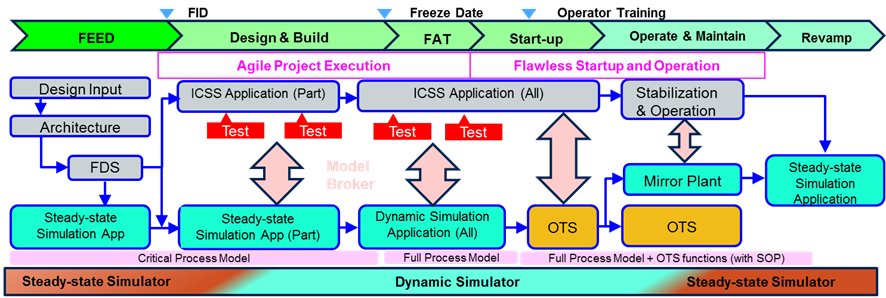

Fig. High-Level OpreX Agile Project Execution Model

OpreX Agile Project Execution은 Yokogawa가 제공하는 혁신적인 프로세스 자동화 시스템 구축 방법론입니다. 이 방식의 목표는 프로젝트를 적시에 완료하면서도 중요 경로에 영향을 주지 않는 유연한 수행입니다. 이를 통해 애플리케이션 소프트웨어 개발, 하드웨어 납품 기반의 공정 일정, 그리고 자동화 시스템의 후반부 변경까지도 유연하게 대응할 수 있습니다.

OpreX 프로세스는 애플리케이션 개발과 하드웨어 제작이 상호 간섭 없이 병행하여 수행될 수 있도록 지원합니다. 이는 위의 그림에서 보여주고 있습니다.

Executive Summary

Value Propositions

Yokogawa의 OpreX Project Execution은 표준화된 기술과 유연한 프로젝트 수행 프로세스를 활용하여 프로젝트 진행 과정에서 자동화가 중요 경로에 영향을 주지 않도록 하는 혁신적인 접근 방식입니다. OpreX 기술 기반 프로젝트를 통해 다음과 같은 효과를 기대할 수 있습니다.

- 프로젝트 수행 비용 절감

- 설치 비용 절감

- 총 소유 비용(TCO) 절감

- 프로젝트 수행 및 납품의 유연성 확보

- 프로젝트 수행 리스크 감소

Goals

OpreX Project Execution이 프로젝트 전 과정에서 추구하는 목표는 다음과 같습니다.

- 자본 프로젝트의 성공 가능성 제고

- 자본 프로젝트 수행 과정에서 자동화 실행이 중요 경로에 영향을 주지 않도록 유지

- 공급 범위에 따라 고품질의 통합 자동화 시스템 제공

- 통합 시스템을 통해 운영 우수성 실현

- 고객 만족에 대한 확고한 약속

Key drivers and Enablers for OpreX Project Execution

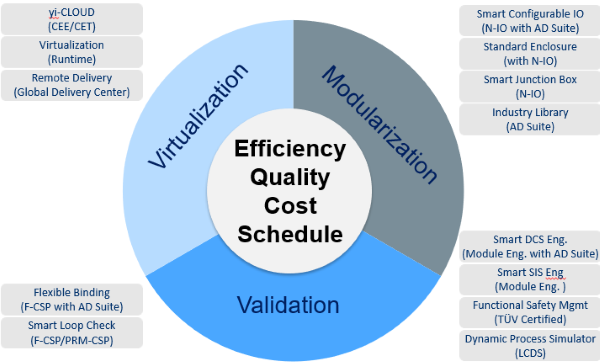

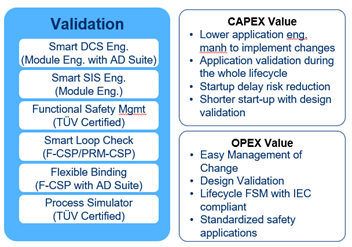

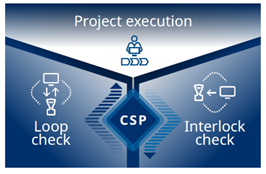

OpreX deivery model에는 세 가지 핵심 동력이 있습니다. 가상화, 모듈화, 검증이며, 이에 따른 실행 요인은 아래 그림에 나타나 있습니다.

Fig. Three key drivers and Enablers

Details

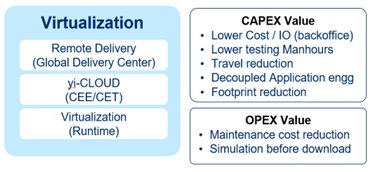

Virtualization

이는 세 가지 솔루션으로 구성되어 있습니다. Remote Delivery 모델, 클라우드 기반 엔지니어링(yi-CLOUD), 그리고 Target System Virtualization입니다.

Fig. Value drivers enabled by Virtulization

Remote Delivery (GDC)

Yokogawa의 글로벌 엔지니어링 리소스 센터(Global Delivery Center)는 OpreX를 구현하도록 교육을 받은 조직으로, 프로젝트 엔지니어링을 수행하고, 제3자 시스템 테스트 및 제어·안전 시스템 테스트를 담당합니다.

yi-CLOUD (CEE/CET)

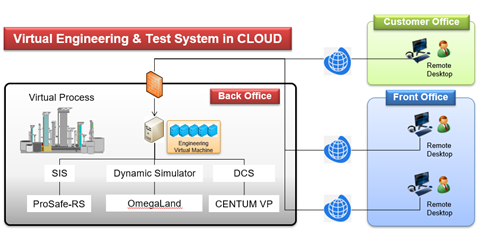

Fig. Virtual Engineering & Test System in Cloud

대상 시스템이 어디에서 개발되든, 팀 구성원이 어디에 있든 상관없이 Cloud Enabled Engineering과 Testing은 이해관계자들, 즉 Yokogawadml front office와 back-office, operations, EPC(s), 그리고 end-users가 프로젝트 애플리케이션 개발을 구현하고 테스트할 수 있는 환경을 제공합니다.

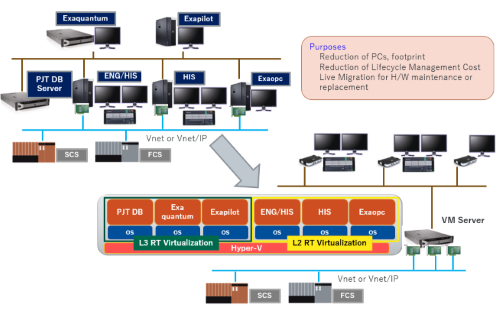

Virtualization (Runtime)

Fig. Runtime Virtualization for Yokogawa ICSS Image zoom

이 기능을 통해 하나의 물리적 서버에서 여러 개의 가상 머신을 실행할 수 있으며, 물리적 PC와 시스템 캐비닛의 수를 줄여 설치 공간, 전력과 발열, 냉각, 유지보수 비용을 절감할 수 있습니다.

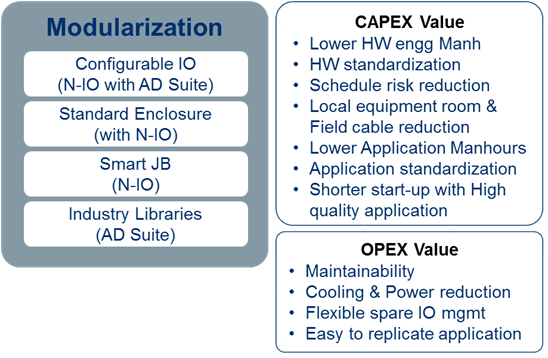

Modularization

It consists of N-IO based Standard Enclosure, Smart Junction Box (Smart JB) as hardware platform and Automation Design Suite (AD Suite) as software platform with Industry Libraries.

Fig. Value Drivers enabled by Modularization

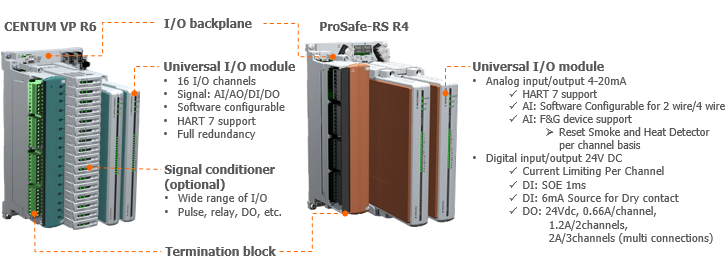

Configurable I/O (N-IO with AD Suite)

N-IO with AD Suite enables application development and hardware manufacturing to occur in parallel without dependencies. N-IO supports multiple signal types on a per-channel basis and simplifies field device wiring, eliminates the need for marshalling systems and supports flexible binding. N-IO eliminates the need for specific wiring assignments and full utilization of all points in a module.

Fig. N-IO Universal I/O module

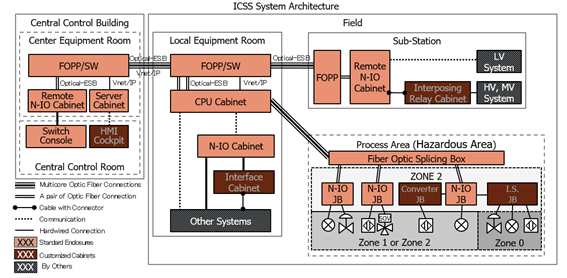

Standard Enclosure (with N-IO)

Fig. Standardized ICSS System Architecture

Standard enclosure enables standardization and ensures consistent design and quality. The use of N-IO eliminates cross-wiring and marshalling cabinet engineering. The I/O cabinet is fully standardized with software configurable I/O. Hardware engineering and the design approval processes are minimized with this standard enclosure approach. In this standards approach, enclosures can be ordered by datasheet without the repetitive recycling of drawing approvals. Everyone - Yokogawa, EPC and customer, benefits from reducing engineering man-hours in the design approval process

Smart JB (N-IO)

Fig. Filed Wiring Reduction by Smart JB

N-IO components are designed to be installed in the field. With Smart JB, field devices can be directly connected to the N-IO system. This Smart JB concept provides a significant benefit during construction. Thick and heavy-weight homerun cables are replaced by thin and light fiber optic cables and power cables. Total cable weight, cost, cable trays, related field engineering and documentation (e.g. loop diagrams) can be significantly reduced.

GES Industry Libraries (AD Suite)

Industry Library is one of the key components of Yokogawa’s Global Engineering Standard (GES) Toolkit as a foundation for the module-based engineering approach and it provides a pragmatic way for knowledge management in industrial automation and improves the application of best practices. The main objectives of the GES Toolkit are:

- To make use of proven implementations (learned from others)

- To enable consistent design & implementations

- To improve implementation efficiency

- To reduce known risks

Validation

It includes the various elements to fulfil requirements.

Smart DCS Engineering (Module Eng. with AD Suite)

Fig. Value Drivers enabled by Validation

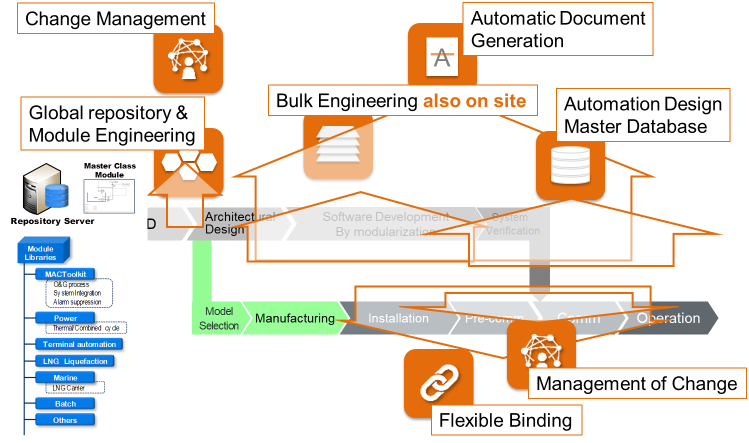

Module-based engineering utilizing Yokogawa’s AD Suite is the unifying element in the OpreX Project Execution approach. AD Suite is the central engineering application and database for all aspects of an automation project. Yokogawa's engineering platform brings features that enable flexibility to project execution and Key features include:

- Bulk Engineering

- Modular application Engineering

- Automated Document Generation

- Late changes and Flexible Binding

- Re-use application assets (GES Industry Library, Customer standard application etc.)

- Change Management for traceability throughout the project lifecycle.

AD Suite retains the entire engineering history of the plant from design phase through commissioning and live operation, ensuring up-to-date plant knowledge with every expansion or hardware and software change throughout the system lifecycle.

Fig. Smart DCS Engineering

Smart SIS Engineering (Module Eng.)

Similar (almost identical) to the DCS application development, modularized application development is executed for Safety, ESD and F&G systems following the OpreX processes and workflows. This includes the use of Smart JB with Universal, Safety N-IO and configurable cabinets. Hardware follows the same application independent process as the DCS and can be shipped as needed for construction. Application development also follows the same modular development process and remote, continuous testing process previously described.

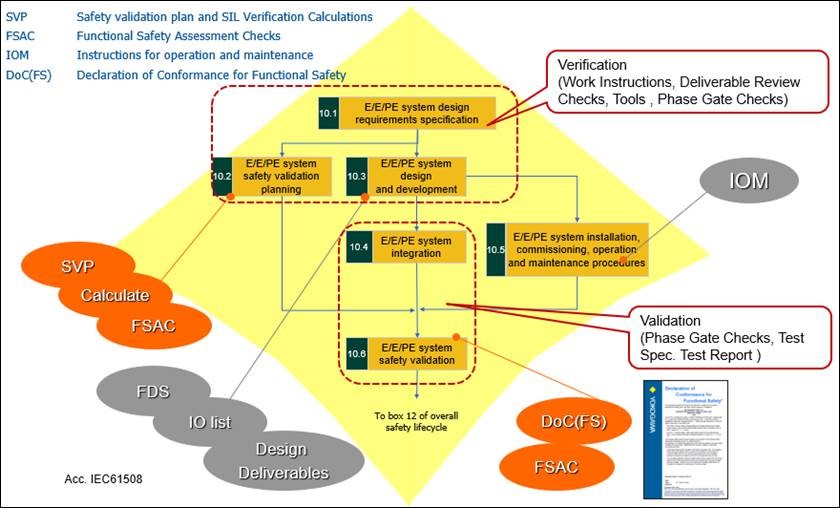

Functional Safety Management (FSM)

FSM is essential for the SIS project execution and it aims to reduce hazardous impact to human life, environment, and property to a socially acceptable risk level throughout a plant’s safety life-cycle. Yokogawa is applying FSM to the realization of Safety Solutions in accordance with the international standards IEC-61508 and IEC-61511. This is achieved by rigorous application of Yokogawa global procedures coupled with independent certification by the internationally respected TÜV Rheinland organization.

Fig. Yokogawa‘s FSM

Commissioning Support Package (F-CSP/PRM CSP)

Early devices and electronic check and site engagement are possible using Yokogawa’s N-IO and Filed – Commissioning Support Package (F-CSP). F-CSP performs N-IO node configuration and Input/Output validation and HART parameter download without the controller present. F-CSP validates the physical side of the field device and IO connection. PRM CSP Commissioning Support Tool can perform loop check automatically for HART devices through field control station. It is the tool supporting the works of connection, loop, range, engineering unit, signal conversion and interlock check for field digital field devices (HART and FOUNDATION Fieldbus H1) during commissioning phase and aims to achieve to:

- Reduce of commissioning time for field devices and its cost

- Improve the quality of commissioning of field devices

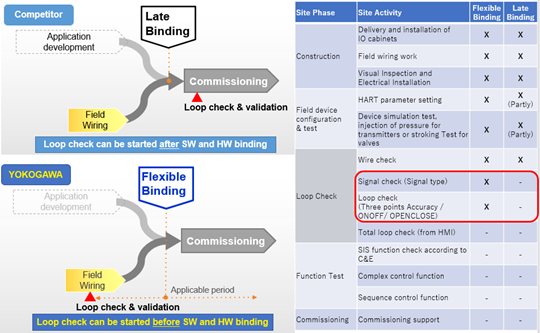

Flexible Binding (F-CSP with AD Suite)

Once the field information is validated by use of the Commissioning Support Package, it is reflected back into the system engineering database. The reflected database automatically binds into the application software. This is known as flexible binding which:

Fig.Late Binding vs Flexible Binding Image Zoom

- Allows for early shipping of Field Enclosures

- Facilitates early completion of field work without requiring the entire system to be ready at site.

- Enables flexible binding with DCS/SIS at any stage of SAT.

- Enables smoother commissioning and start-up.

- Accommodates late changes

The system has the full capability to accommodate any late modification and late change without compromising the overall project schedule.

Process Simulator (LCDS)

Dynamic Process Simulation has evolved over recent years. This has enabled simulation technology and a Life-Cycle Dynamic Simulator (LCDS) to be widely applied. The primary deliverables of LCDS throughout the project life-cycle are:

- Dynamic Process Simulation Model - Development of the process plant dynamic simulation model

- ICSS configurations & integration - Integration of the dynamic process model with an emulation of the automation system configuration

- ICSS Checkout - Testing with pre-defined operating scenarios (start-up, operations, abnormal conditions, alarm management)

- Operator Training – Testing of new ICSS platform, Standard Operating Procedure (SOP) validation and competency verification for initial and refresher training

LCDS deliverables can be progressively developed, used, re-used, and enhanced throughout the design & build and operation & maintenance phases of the project.

Foundation for Life-Cycle Management

Once the project has been turned over to the operations team, the OpreX methods provide the foundation for a sustainable plant all of the automation systems in the plant. A sustainable plant is Yokogawa‘s concept to maintain and improve the installed automation system providing a safe, secure, and robust installation at the lowest possible lifecycle cost. For more detail information, please check Sustainable Plant and Yokogawa System Upgrade Solution.

기술 및 솔루션, 요꼬가와에 대한 자세한 정보를 찾고 계십니까?

견적 및 기술문의