청정 수소 시대가 열렸습니다. 가능성은 무궁무진하지만, 앞으로 나아가는 길은 복잡합니다. 청정 수소 사업을 확장하려면 수요 확보, 정책 불확실성 관리, 수요 예측과 같은 과제를 해결해야 합니다. 또한 자금 확보, 운영 규모 확대, 화석 연료 대비 비용 경쟁력 유지 등 지속적인 과제도 함께 관리해야 합니다.

Opportunities for Scalable Growth

효과적인 디지털화를 통해서만 운영을 간소화하고 효율을 최적화하며 필요할 때 공급망 정보를 즉시 확인할 수 있어 시장 변화에 선제적이고 신속하게 대응할 수 있습니다. 배출을 최소화하고 공정 자동화로 창출된 효율을 극대화할 수 있습니다. ESG 목표를 달성하면서도 수익성을 극대화하고 개방형·벤더 독립형 시스템을 활용해 민첩성과 생산성을 높일 수 있습니다.

Plot a Roadmap to Success

Yokogawa의 종합 솔루션은 IT와 OT 전 영역을 아우르며 수소의 생산, 저장, 운송, 활용 전 과정에서 최적의 위치를 확보할 수 있도록 지원합니다. 급변하는 에너지 환경 속에서 Yokogawa는 고객과 함께 에너지 전환과 탈탄소화를 추진합니다.

Details

2024년 Yokogawa는 재생에너지 소프트웨어 솔루션 분야의 글로벌 선도 기업인 BaxEnergy를 인수했습니다. BaxEnergy의 수소용 자산 성능 관리(APM) 시스템인 Energy Studio Pro®는 고급 분석 및 최적화 기능을 제공하여 병목 현상을 식별하고 에너지 소비를 최적화하며 플랜트 전반의 성능을 향상시켜, 보다 지속 가능하고 비용 효율적인 수소 생산 과정에 기여합니다.

수소 순도, 압력, 온도, 유량 등 주요 파라미터를 실시간으로 모니터링함으로써 당사 플랫폼은 예측 유지보수, 조기 이상 감지, 적시 대응을 가능하게 하여 가동 중단을 최소화하고 수소 생산량을 극대화합니다.

Energy Studio Pro® 는 수소 발전소에 최첨단 소프트웨어 솔루션을 제공하여 생산을 모니터링, 제어 및 최적화할 수 있도록 지원합니다.

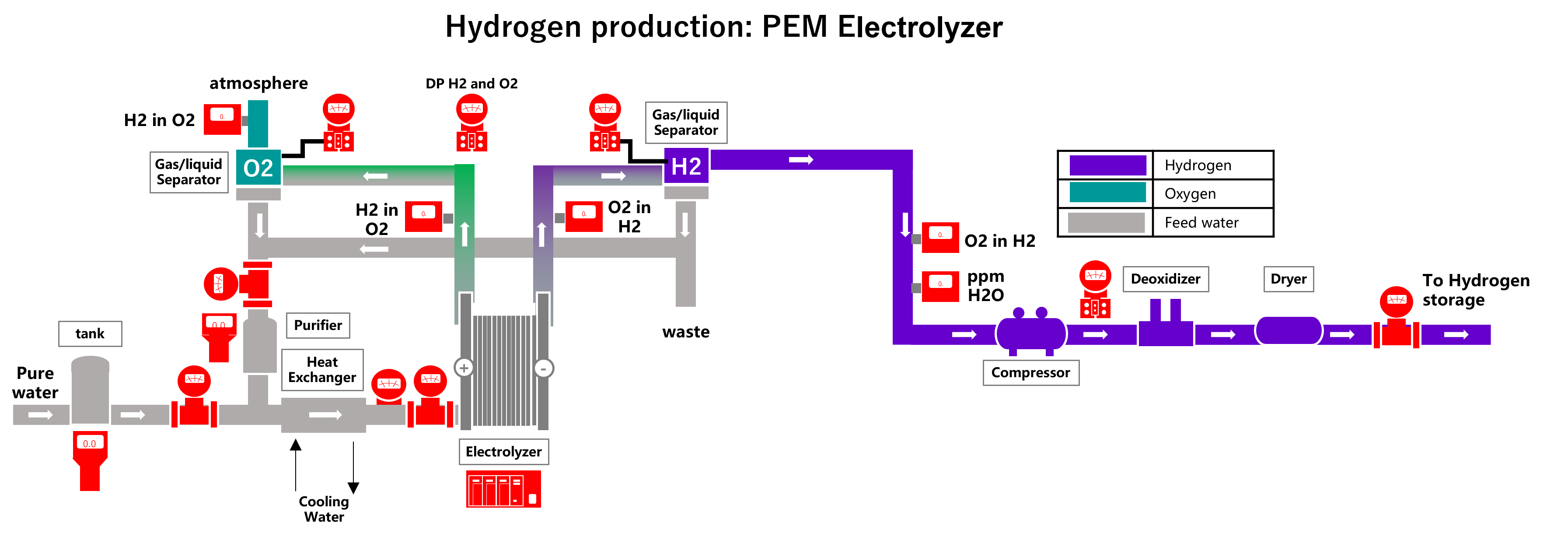

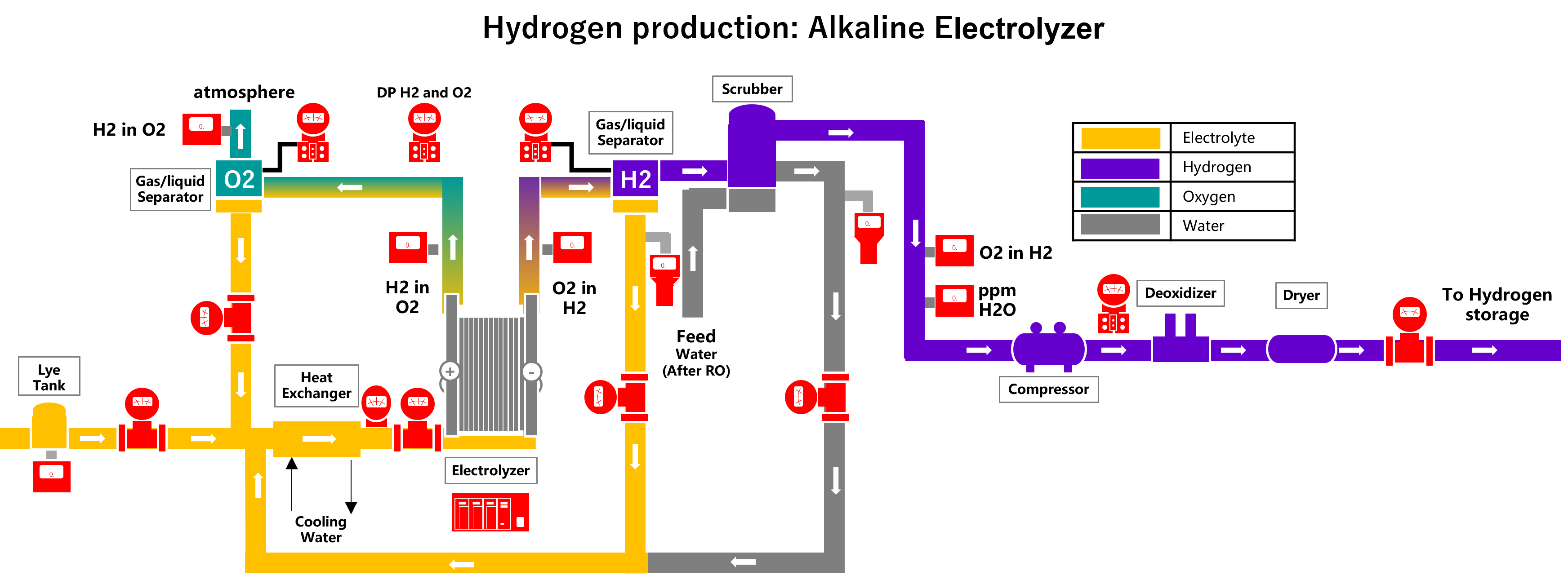

물과 전기를 이용해 수소를 생산하는 전해조는 핵심 기술입니다. 전해조에는 양성자 교환막(PEM) 전해와 알칼리 전해의 두 가지 주요 기술이 있습니다. 특히 재생에너지로 구동되는 전해조 시장은 향후 수십 년간 크게 성장할 것으로 예상되며, 단순한 새로운 수소 공급원을 넘어 정유, 질소 비료 생산 등 기존 수소 설비를 대체하는 역할도 할 것으로 보입니다.

|

|

|

|

|

|

| Flowmeter | Differential pressure /Pressure Transmitter |

Temperature Transmitter |

Gas/Liquid Analyzer | Conductivity Sensor |

|

|

|

|

|

|

| Flowmeter | Differential pressure /Pressure Transmitter |

Temperature Transmitter |

Gas/Liquid Analyzer | Conductivity Sensor |

모든 제조 산업에서 공정 파라미터를 정확하게 측정하고 모니터링하는 것은 생산 효율 향상과 안전, 제품 품질 확보를 위해 매우 중요합니다. 수소는 폭발 가능성이 있는 물질이므로 세심한 공정 관리가 요구됩니다. 또한 그린 수소의 생산 비용은 여전히 큰 과제로 남아 있습니다. 이와 관련해 생산성 향상과 장비 수명 연장은 비용 절감을 위한 시급한 과제입니다. Yokogawa는 높은 신뢰성과 첨단 기술을 바탕으로 전해조 분야에서 고객에게 기여할 수 있는 제품과 서비스를 제공하는 데 최선을 다하고 있습니다.

자료실

Downloads

Brochures

- Integrating the Hydrogen Ecosystem (9.5 MB)

News

-

Press Release | Corporate 2024년10월28일 Yokogawa, 유럽 해상 풍력 발전소의 선구적 녹색 수소 플랫폼을 위한 통합 자동화 및 모니터링 시스템 제공

- 재생 에너지 저장을 위한 해상 녹색 수소 생산 플랫폼 -

-

Press Release | Corporate 2024년6월5일 Yokogawa, 재생 에너지 관리 솔루션 제공업체인 BaxEnergy 인수

- 40개국 이상에서 120GW 이상의 재생에너지 운영을 통해 성과 입증 -

-

Press Release | Corporate 2024년2월21일 Yokogawa, Tsubame BHB에 투자 및 업무제휴각서 체결

- 암모니아 생산을 위한 솔루션 공동개발 등 협업 -

-

Press Release | Projects 2023년9월25일 Yokogawa와 로테르담 항, 산업 전반에 걸친 에너지 및 자원 효율성 향상 연구 시작

-

Press Release | Projects 2023년9월5일 Yokogawa, 호주 유리 그린 수소 프로젝트에 에너지 관리 시스템 제공

-플랜트 시설 제어 및 에너지 관리 시스템 통합-

Related Products & Solutions

-

압력 전송기

Yokogawa 압력 전송기로 프로세스 압력을 정확하고 안정적으로 측정하면 안전하고 신뢰할 수 있으며 수익성 있는 작업을 지원할 수 있습니다.

-

온도 전송기

Yokogawa는 head-mount형, panel-mount형 또는 field-mount형 온도 전송기 제품 군을 제공합니다.

-

Conductivity Analyzers

전도도 측정기, 분석기 및 송신기는 전도도, 저항, WIFI, 탈염수, RO수, 농도 백분율, 보일러 블로우다운 및 TDS의 연속 공정 측정 및 모니터링에 사용됩니다.

-

ROTAMASS Total Insight

이 제품은 지금까지 기술적으로 가장 진보 된 질량 유량계입니다. 우수한 디자인을 가진 특유의 유량 센서와 전송기 어플리케이션과 Total Insight 철학과 기능성을 결합함으로써, ROTAMASS가 변화하는 요구 사항에 적응할 수 있는 유연성으로 공정 측정 수명주기 전반에 걸쳐 성능을 보장합니다.

-

CA Series

CA Series는 슬러리(Slurry) 유체와 점착성(Adhesive) 유체와 같이 측정하기 어려운 유체에도 안정된 측정을 제공합니다.

'Total Insight' 컨셉을 기반으로 고객들의 작업용이성과 유지보수성을 향상시킵니다.

-

와류 유량계 VY

Yokogawa 최신 와류 유량계

(DY 후속 모델)

-

Liquid Density Analyzer DM8C, VD6

DM8 액체 밀도 분석계는 일반적인 공정 액체의 밀도를 고감도 및 우수한 안정성으로 측정합니다. 측정 밀도 범위는 0 ~ 2.0 g/cm3이며, 유량과 점도에 영향을 받지 않습니다. 범용 센서 외에 위생 타입 및 방폭형 센서도 있습니다.

-

GD402 Analyzer

모델 GD402 가스 밀도 분석계 및 모델 GD40 디텍터는 가스 밀도의 연속 측정뿐만 아니라 비중 및 분자량을 포함한 몇 가지 중요한 파라미터를 제공합니다. 모델 GD402는 비방폭 및 방폭 어플리케이션에 대한 요구 사항을 충족하기 위하여 두 가지 버전으로 설계된 마이크로 프로세서 기반의 컨버터 입니다.

-

In-Situ Gas Analyzer TDLS8000

Yokogawa의 새로 TDLS™8000은 업계 최고의 기능을 하나의 견고한 장치에 모두 탑재하고 있습니다. 이 플랫폼 설계는 샘플 추출 및 컨디셔닝이 필요 없는 현장 측정을 위한 것입니다.

기술 및 솔루션, 요꼬가와에 대한 자세한 정보를 찾고 계십니까?

견적 및 기술문의