Upcoming Events

-

Event | Webinar Jan 15, 2026 3:00 PM Building and Expanding Safety: Bridging People, Technology and Culture

Make safety decisions clear, timely, and consistent—so high-risk work, exposure, and audits are handled with confidence.

High-hazard work and SIMOPS need clear permissions, clean isolations, traceable evidence, and secure practices. Here’s a practical way to standardize control of work, embed compliance, reduce exposure, and tighten both physical safety and cyber security measures — without unnecessary admin.

What you’ll get on this page

- A staged approach you can run with existing systems

- Clear KPIs

- Short Use Cases with links to OpreX™ Integrated Solutions pages

Why Yokogawa

- Scalable permit-to-work that covers every role, including contractors

- A knowledge-driven core for safer and faster permitting across industries

- Global deployments and support in high-risk environments with proven outcomes

Overview

- Challenge

Permits, isolations, and risk reviews sit apart; hazardous inspections raise exposure; evidence is manual; access controls are uneven. - Approach

One experience—standardized control of work → evidence-by-design → exposure reduction(remote/assisted inspection)→ physical & cyber hygiene. - Outcomes

Fewer incidents and findings, faster safe-to-start, clearer accountability, lower exposure. - Primary KPIs

TRIR (Total Recordable Incident Rate), LTI (Lost Time Injuries), permit issue-to-start time, isolation link accuracy, overdue maintenance backlog, audit findings closure time.

We describe methods and typical goals. Actual outcomes vary by site conditions, data quality, and operating constraints.

-

Advanced worker safety for LNG facilities

Strengthen LNG safety with OpreX™ Control of Work - streamlined permits, real-time tracking, and reliable hazard management.

-

Efficient detection of oil tank corrosion and leaks with drones

Prevent oil leaks and corrosion with early detection using drones for efficient maintenance.

-

Elevate workplace safety for operators and engineers with immersive VR risk training

Strengthen safety for operators and engineers with VR risk scenarios. Practice handling fires and gas leaks in a realistic virtual space, boosting emergency readiness and reducing accident potential. Build a workplace where everyone can work with greater confidence.

-

Ensure safety by reducing gas leakage risk with drones

Protect workers and the environment by detecting gas leaks early using drones with gas sensors.

-

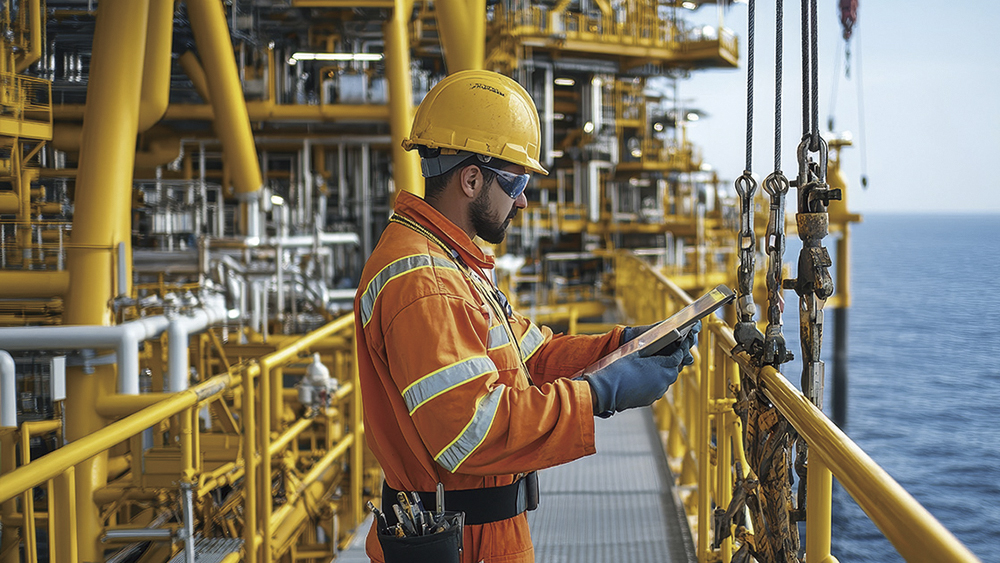

Industry-leading control of work safety for offshore

Boost offshore safety with OpreX™ Control of Work - robust risk assessment, isolation oversight, and compliance in harsh environments.

-

Mitigate risk for port worker safety

Optimize port operations with OpreX™ Control of Work - digital mapping, real-time coordination, and safer workflows in dynamic environments.

-

Optimize pharma & biopharma worker safety

Elevate pharma/biopharma safety with OpreX™ control of work - real-time risk insights, robust compliance, and minimal time-on-tools impact.

-

Cybersecurity Management

Yokogawa’s cybersecurity services take a lifecycle approach to help customers control the security risks and manage them to achieve the highest business continuity plan.

Details

Challenges

Do any of these sound familiar in your operations?

Establishing a safety culture & preventing incidents

- Procedures and isolations vary by person or shift

- Roles and approvals aren’t always clear

Regulatory compliance & audit preparedness

- Evidence sits in multiple places

- Corrective actions are hard to track through to closure

Risk management & incident response

- SIMOPS and high-risk inspections carry exposure

- Early detection and first actions are uneven

Physical & cyber security

- Site access, keys, and OT connections are inconsistently controlled

- Responsibilities blur at interfaces

How Yokogawa helps

Practical ways to address these challenges with your team

Standardize control of work

- Put permits, isolations, risk assessment, and approvals in one flow with clear roles and gates

- Make “safe-to-start” visible

Build “compliance by design”

- Capture evidence as part of doing the work

- Route findings and corrective actions with owners and due dates

- Review closure weekly

Reduce exposure & clarify first response

- Use remote/assisted inspection for hard-to-reach areas

- Define who acts, how fast, and with what checks when events occur

Tighten physical safety and cyber security

- Simplify access rules (people/areas/systems), log exceptions, and rehearse recovery steps

- Keep responsibilities explicit at interfaces

Use Case

[Case 1] One flow for permits, isolations, and approvals

When these steps live apart, readiness is ambiguous and delays grow. Unify roles, gates, and evidence so “safe-to-start” is visible and preventable incidents and audit findings are reduced.

Team achieves

- Faster permit issue-to-start time

- Fewer hand-off and linkage errors

- Clear ownership and accountability by role

![[Case1] One flow for permits, isolations, and approvals](http://web-material3.yokogawa.com/1/38671/tabs/safety_risk_compliance_uc_pic01.jpg)

[Case 2] Remote/assisted inspection to reduce exposure & verify early

Hard-to-reach checks raise exposure and slow confirmation. Use remote/assisted observation to surface early signals, capture evidence, and trigger rapid first response while lowering field time.

Team achieves

- Reduced exposure hours for risky checks

- Earlier condition confirmation with evidence

- Faster escalation to the right owner

![[Case2] Remote/assisted inspection to reduce exposure & verify early](http://web-material3.yokogawa.com/1/38671/tabs/safety_risk_compliance_uc_pic04.jpg)

[Case 3] Risk awareness for low-frequency, high-hazard scenarios

Because these events are rare, responses vary by person and shift. Simulate the sequence, make verification steps explicit, and rehearse until hesitation drops to lower incident likelihood.

Team achieves

- Confident first moves under stress

- Consistent verification before start

- Lower frequency of abnormal events

![[Case3] Risk awareness for low-frequency, high-hazard scenarios](http://web-material3.yokogawa.com/1/38671/tabs/safety_risk_compliance_uc_pic07.jpg)

[Case 4] Interface & SIMOPS safety (people–cargo–vehicle)

At interfaces, responsibilities blur and risks stack across parties. Share the same checks, owners, and timers so multi-party work starts and finishes under common safeguards.

Team achieves

- Fewer near-misses at interfaces

- Faster coordination across crews and contractors

- Cleaner, traceable audit trails

![[Case4] Interface & SIMOPS safety (people–cargo–vehicle)](http://web-material3.yokogawa.com/1/38671/tabs/safety_risk_compliance_uc_pic09.jpg)

Solution Pick Up

-

OpreX Control of Work

Yokogawa’s Control of Work solutions provide you with best practice knowledge gained over 25 years by implementing solutions in highly hazardous environments.

-

Industry-leading control of work safety for offshore

Boost offshore safety with OpreX™ Control of Work - robust risk assessment, isolation oversight, and compliance in harsh environments.

-

Advanced worker safety for LNG facilities

Strengthen LNG safety with OpreX™ Control of Work - streamlined permits, real-time tracking, and reliable hazard management.

-

Ensure safety by reducing gas leakage risk with drones

Protect workers and the environment by detecting gas leaks early using drones with gas sensors.

-

Efficient detection of oil tank corrosion and leaks with drones

Prevent oil leaks and corrosion with early detection using drones for efficient maintenance.

-

Elevate workplace safety for operators and engineers with immersive VR risk training

Strengthen safety for operators and engineers with VR risk scenarios. Practice handling fires and gas leaks in a realistic virtual space, boosting emergency readiness and reducing accident potential. Build a workplace where everyone can work with greater confidence.

-

Mitigate risk for port worker safety

Optimize port operations with OpreX™ Control of Work - digital mapping, real-time coordination, and safer workflows in dynamic environments.

-

Safe and efficient monitoring of power transmission grid with drones

Enhance power transmission safety with drones for fast, efficient monitoring and reduced risks.

-

Safe and secure wind turbine blade inspection with drones

Increase safety and efficiency by using drones to inspect wind turbine blades without high-altitude risks.

Looking for more information on our people, technology and solutions?

Contact Us