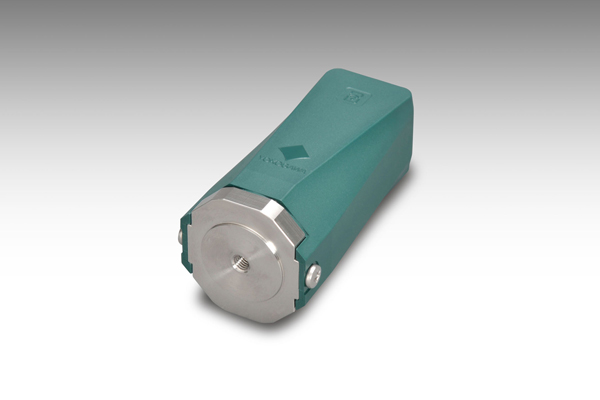

This product acts as a battery-powered wireless vibration sensor with the sensor and wireless communication functions integrated in a unit and it is suitable for Industrial IoT (IIoT) applications. XS770A Wireless Vibration Sensor measures vibration (velocity and acceleration) along the X, Y, and Z axes and 3-axis composite in addition to monitoring the surface temperature of the bottom and transmits the measurement data to the host systems via wireless communication. The XS770A can be mounted easily by a screw or a magnet.

Supporting in Hazardous Location Installation

The XS770A can be installed in Zone 2 areas, such as petrochemical plants, paint plants, drug plants, where flammable gas or vapor may exist.

Long-Distance Communication on License-free Bands

XS770A has adopted LoRaWAN. LoRaWAN has excellent sensitivity reception, good radio interference resistance, and offers a communication distance of 10 km or more in an ideal communication environment. This sensor can be installed this sensor anywhere you want over vast area.

Battery-powered Compact Wireless Sensor with the environmental resistance

The XS770A is compact and has excellent environment resistance characteristics. It can be installed in a plant where wiring is difficult. With a number of sensors, various data can be collected for plant maintenance by early detection and prediction of equipment failure.

Configuration And Status Monitoring Using Smartphone

Using an Android-based smartphone with NFC (Near Field Communication) interface makes configuration and status monitoring of sensors simple and intuitive.

About OpreX

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business and stands for excellence in the related technology and solutions. It consists of categories and families under each category. This product belongs to the OpreX Asset Management and Integrity family that is aligned under the OpreX Transformation category.

Details

XS770A Wireless Vibration Sensor

| WIRELESS SPECIFICATIONS | Communication Protocol | LoRaWAN class A EU868, AS923, US915, KR920, AU915 |

||

|---|---|---|---|---|

| Data Rate | 250 to 11000 bps*1 | |||

| Frequency | Available frequency bands vary depending on the country. Please check General Specifications for details. |

|||

| Radio Security | AES 128-bit encryption | |||

| RF Transmitter Power | Max. 7 dBm | |||

| Antenna | Built-in Omni-directional antenna | |||

| POWER SUPPLY SPECIFICATIONS | Battery | Lithium thionyl chloride battery: 1 unit (dedicated product) Rated voltage: 3.6 V Rated capacity: 2.6 Ah |

||

| PERFORMANCE SPECIFICATIONS | Measurement | Vibration | Measurement | Acceleration (peak), Velocity (RMS) |

| Axis | X, Y, Z axes and 3-axis composite | |||

| Range *2 | Acceleration: 0 to 130 m/s2 (0 to 13.26 g) Velocity *3: 0 to 20 mm/s (0 to 0.79 in/s) |

|||

| Frequency range | 10 to 1,000 Hz (± 3 dB) | |||

| Accuracy (100 Hz) | X, Y, Z axes : ±10% FS 3-axis composite: ±20% FS |

|||

| Temperature | Measurement | Temperature | ||

| Range | -20 to 85°C (-4 to 185°F) | |||

| Resolution | 0.1°C | |||

| Measurement part | Base | |||

| Update Time | 1 minute to 3 days | |||

| Battery Characteristics | The typical battery life is 4 years in the following conditions.*4 • Update period: 1 hour • Ambient temperature: 23±2°C (73.4±3.6°F) |

|||

| FUNCTIONAL SPECIFICATIONS | Output | LoRaWAN*5 | ||

| NFC Interface | NFC Forum Type 2 Tag | |||

| INSTALLATION ENVIRONMENT | Ambient Temperature Limits | Operating: -20 to 85°C (-4 to 185°F)*6 | ||

| REGULATORY COMPLIANCE STATEMENTS | Degrees of Protection | IP66/IP67 and Type 4X*6 | ||

| Explosionproof | ATEX, IECEx, FM | |||

| PHYSICAL SPECIFICATIONS | Housing Material | For detail, refer to “MODEL AND SUFFIX CODES” in General Specifications. | ||

| Weight | 260 g (0.57 lb) | |||

| Mounting | Mounting on the measurement target using the screw*7 | |||

*1: Available data rate vary depending on the country.

*2: Peak value of the input vibration. For the relation between the measurement frequency band and measurable range, refer to General Specifications.

*3: The 20 mm/s pk value is equivalent to 14 mm/s RMS when input is based on a sine wave.

*4: Environmental condition such as vibration and the type of the connected device may affect battery life.

*5: For detail on channel plan, refer to General Specifications.

*6: Depends on the selected code. For detail, refer to General Specifications.

*7: Can also mount using the magnetic holder supplied as an accessory. Note that, when using the magnetic holder, the vibration measurement frequency band drops.

Sushi Sensor App

This software is used to perform the setting and status check of this product via the NFC interface.

| Operating Environment | Item | Recommended System Requirements |

|---|---|---|

| OS | Android 5.1.1 or higher | |

| CPU | Snapdragon 800 or better | |

| Resolution | 1280 x 720 dots or more | |

| NFC | Readers, Writer | |

| GPS | Optional |

Resources

Kyowa Hakko Bio monitors vibration trends with Yokogawa's Sushi Sensors to prevent unexpected equipment failures.

By using eServ, sensor data and maintenance information are shared with everyone involved in manufacturing.

The City of Eugene contracted Yokogawa for the challenging solution to enhance their control system with a secure wireless network to operate a wastewater treatment facility with a peak capacity of 277 million gallons daily using five processes.

Maintaining the reliable performance of a furnace fan allows operators to avoid wasting large batches, which sometimes require days of heat-treat processing.

Automated wireless vibration monitoring improves safety and exposes rotating equipment (rollers, driers, etc.) conditions in polyester textile production lines.

This eBook explains why implementing IIoT based digital operator monitoring solutions for autonomous anomaly detection enhances operations.

Optimizing automated equipment condition monitoring calls for a different wireless protocol than that used with process instruments.

Wireless sensors and the network can reduce expenses

Downloads

Brochures

Instruction Manuals

General Specifications

- XS770A Wireless Vibration Sensor (767 KB)

Engineering Tools

- XS770A Wireless Vibration Sensor (549 KB)

Videos

The measurement, collection and utilization of equipment data by the Industrial IoT (IIoT) wireless solution “Sushi Sensor” contributes to efficient equipment maintenance and open a new road to a Smart Factory.

Looking for more information on our people, technology and solutions?

Contact Us