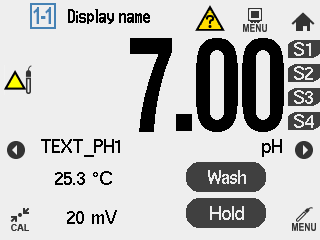

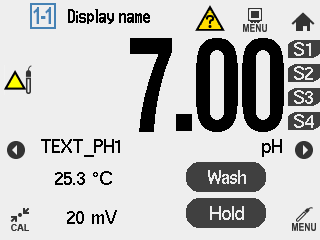

FLXA402는 다양한 연결 가능성을 제공하여 여러 분석기가 필요하지 않도록 하며 높은 유연성을 제공합니다. 이 4-wire 분석기에는 컬러 HMI 및 간편한 터치스크린 작동을 지원하며, 9개 언어를 지원하는 간단한 메뉴 구조를 사용하여 간편하고 효율적인 설정 및 구성이 가능합니다.

FLXA402 분석기는 모듈식 디자인으로 pH/ORP, 저항/전도도 (SC), 유도 전도도 (ISC), 백분율 농도, 용존 산소 (DO) 및 4-20mA 입력을 포함한 센서 모듈과 함께 다양한 측정 옵션을 제공합니다. 듀얼 센서 측정은 사용자가 정의할 수 있는 계산된 데이터 기능과 같은 추가 기능을 제공합니다.

OpreX에 대하여

OpreX는 Yokogawa의 산업 자동화 및 제어 비즈니스를 포괄하는 브랜드로, 관련 기술과 솔루션의 탁월함을 상징합니다. 이는 각 카테고리 및 해당 카테고리 하위의 제품군으로 구성되어 있습니다. 이 제품은 OpreX 측정 카테고리 하에 정렬된 OpreX 분석기 제품군에 속합니다.

Details

FLXA402 특징

다섯 개의 센서까지 지원

FLXA402는 최대 다섯 개의 센서를 연결할 수 있어 유지 보수 중에도 중단 없는 측정을 실현할 수 있습니다. 다중 센서 측정은 다양한 계산된 데이터 및 분석기를 중복 시스템으로 프로그래밍하는 옵션과 함께 추가 기능을 제공합니다.

고급 기능

FLXA402는 하나의 분석기로 pH/ORP, 접촉 전도도(SC), 유도 전도도(ISC), 용존 산소(DO), 그리고 자체 진단 기능을 갖춘 광학 용존 산소 센서와 같은 센서를 지원할 수 있습니다. 추가 기능으로는 다음이 포함됩니다:

- 센서 임피던스, 비대칭 전위, 기울기의 지속적인 측정 및 전극 오염/손상, 소모, 측정 액체 수준 감소(예: pH 분석기)에 대한 지속적인 모니터링

- 유지보수 시기 예측을 위한 온라인 센서 상태 확인

Expert Guide: 원활한 작동을 위한 터치 패널 디스플레이

Expert Guide: 원활한 작동을 위한 터치 패널 디스플레이

FLEXA™ 시리즈 분석기는 직관적인 터치스크린 작동으로 보다 개선된 작동성을 제공하며, 9개 언어를 지원하여 사용자 친화적입니다. 센서 상태 및 유지보수 시기 예측은 측정의 효율성을 향상시킵니다. 상호작용 가능한 스크린은 견고한 알루미늄 하우징으로 이루어져 있습니다.

향상된 유연성: 확장성을 위한 모듈식 디자인

FLEXA™ 시리즈 분석기는 교체 가능한 센서 모듈을 갖춘 모듈식 디자인을 특징으로 하며, 다양한 시스템을 구축할 수 있습니다. FLXA402는 최대 다섯 개의 센서를 연결할 수 있어 CAPEX와 OPEX를 줄일 수 있습니다.

미래를 위한 준비

미래를 위한 준비

산업 자동화는 스마트 제품을 향해 진화하고 있으며, 센서는 아날로그에서 디지털 SMART로 변화하고 있습니다. 이러한 변화는 공장 운영에 영향을 미칠 수 있으며 완전히 구현하기까지는 시간이 걸릴 수 있습니다.

높은 성능의 분석기로서의 기능 외에도, FLXA402는 새로운 Yokogawa SENCOM 4.0 플랫폼 구성 요소입니다. 이 플랫폼은 현장 유지보수와 Calibration을 간소화하는 스마트 센서 시스템입니다. SENCOM 4.0 플랫폼을 사용하면 다음 세대 SMART 제품으로의 업그레이드가 쉬우며, 언제든지 업그레이드 할 수 있습니다.

Data Mobility

SD 카드 또는 이더넷을 통한 쉬운 데이터 전송 및 원격 서비스로 보다 심층적인 공정 분석이 가능합니다.

자료실

Wet scrubbers are used in utilities, paper mills, and chemical plants to remove sulfur dioxide (SO2) and other pollutants from gas streams. Undesirable pollutants are removed by contacting the gases with an aqueous solution or slurry containing a sorbent. The most common sorbents are lime, Ca(OH)2, and limestone, CaCO3.

There are a number of suppliers of oil and fat products used for edible purposes. These products include, but are not limited to olive oil, peanut oil, soybean oil, sunflower oil, lard, shortening, butter, and margarine. The raw materials for these products include animal by-products, fleshy fruits (palm and olive), and oilseeds.

Industry:Food and Beverage

In a batch tank, analyzers such as dissolved oxygen (DO) analyzers, oxidation-reduction potential (ORP) meters, and mixed liquor suspended solid (MLSS) analyzers are used. To reduce the maintenance frequency, measures must be taken to prevent dirt accumulation on the sensor. As the liquid level in a tank can vary greatly, great care should be taken when selecting the sensor installation position in a tank.

For control of batch neutralization, a pH measurement coupled with a timer-controlled chemical feed scheme provides very satisfactory results.

This system can be adapted for either acid waste or alkaline waste neutralization.

Continuous technology improvement is ongoing in the pulp & paper industry to obtain the best possible performance. The improved plant performance translates to the higher quality improvement and lower cost, and simultaneously environmental friendly plant operation.

Brewery is facility to produce beer. Breweries process is the manufacturing process of beer, which is a fermented beverage with low alcohol content made from various types of grain. Wheat, maize and other grains can be used for this. Brewing process starts from malted barley that is to form a mash by milling and mixing with hot water. The malt starches are converted to sugars during this process. This sugar rich water is then strained through the bottom of the mash and will be called as "wort". Then the wort will be brought to boil by bringing to the brew kettle. For bitterness or aroma hops are to be added at different times during the boil. Then the wort is cooled and aerated. And brewers yeast is added for fermentation. From the sweet wort the yeast produces carbon dioxide, alcohol and other byproducts. The GREEN BEER undergoes maturation after fermentation. Filtaration and carbonation are the last steps. Finally the beer will be stay in holding tank until it is bottled or kegged.

The proliferation of microorganisms and the resultant formation of slime is a problem which commonly occurs in aqueous systems. Problematic slime producing microbes may include bacteria, fungi and/or algae. Slime deposits typically occur in many industrial aqueous systems including cooling water systems, pulp and paper mill systems, petroleum operations, clay and pigment slurries, recreational water systems, air washer systems, decorative fountains, food, beverage, and industrial process pasteurizers, sweetwater systems, gas scrubber systems, latex systems, industrial lubricants, cutting fluids, etc.

Industry:Refining, Food and beverage, Power, Oil and Gas, Pulp and Paper, Chemical

For safe and efficient operation, the quality of feedwater, steam, and condensate in boiler plants must be controlled and maintained in the most favorable conditions.

One of the primary applications for high purity water is for boiler feed water. The measurement of pure water pH can be one of the quickest indicators of process contamination in the production or distribution of pure water. Effective chemical treatment of the feed water is vital in maintaining the useful operating life and minimizing maintenance costs of the boiler.

Industry:Power, Pharmaceutical, Common

Seawater leak detection is the post-condensation water quality management processes. Damage to the ion exchange resin, which deionizes the supplied water, is also monitored during this process, and both of these applications are executed by a conductivity analyzer. (AN10D01P01-01E)

Process liquid analyzers such as pH meters, conductivity meters, ORP meters, and density meters play an important role at electrolysis plants in the control of concentrations of various process solutions. This requires both precision and stability under harsh conditions that include highly corrosive substances, high temperatures, and many impurities.

In the past, the boiler feed tank systems in sugar factories had to be checked several times a day to make sure there were no sugar solution leaks. This was a very laborious process and, as continuous monitoring was not possible, monitoring results were not reliable. When a leak occurred, recovery operations were very costly and time-consuming. (AN10D01K01-02E)

In a semiconductor plant, a variety of chemicals are used in various manufacturing processes. The chemicals used for specific purposes are produced by diluting raw liquid with demineralized water using in diluting equipment, and the control of the concentration at this point is performed by conductivity measurement.

The treatment of wastewater from pulp and paper plants is a serious environmental concern. Yokogawa's submersion holder with an ultrasonic+air-jet cleaner (customized product) can reduce the manual cleaning frequency to just once every one or two months.

Industry:Pulp & Paper

Wastes have been considered to be a serious worldwide environmental problem in recent years. Because of increasing pollution, these wastes should be treated. However, industrial wastes can contain a number of valuable organic components. Recovery of these components is important economically. Using conventional distillation techniques, the separation of acetic acid and water is both impractical and uneconomical, because it often requires large number of trays and a high reflux ratio. In practice special techniques are used depending on the concentration of acetic acid.

In the manufacturing process of Pharmaceutical, Chemical and Food & Beverage industries, the cleaning and sterilization of tanks and piping are done with various cleaning solutions, fresh or hot water and steam after manufacturing products. Clean-In-Place (CIP) is the system designed for automatic cleaning and disinfecting.

Cyanide-bearing wastewater from mining and electroplating facilities and certain types of chemical plants is toxic and must be treated by oxidation with chlorine or chloride to bring the cyanide concentration within regulatory limits.

Industry:Electrical and Electronics

Continuous technology improvement is ongoing in the pulp & paper industry to obtain the best possible performance. Problems at the wet end (stock preparation) can rarely be corrected downstream. That is why monitoring and controlling pH in pulp stock is critical to the paper making process. Essentially, at every stage in the manufacture of paper, correct pH values play a vital role.

The control of the world's water resource is arguably one of the most important issues. Water demand from industry and domestic users is set to rise throughout the industrialized world. Yokogawa has been applying minimized maintenance measurement systems.

Reverse osmosis (RO) is a separation process that uses pressure to force a solution through a membrane that retains the solute on one side and allows the pure solvent to pass to the other side. More formally, it is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure.

Wastewater from electroplating facilities and certain types of chemical plants contains toxic forms of hexavalent chromium such as chromate and dichromate. The hexavalent chromium in this wastewater must be reduced before the water can be discharged. This requires a two-step process: hexavalent chromium (CR6) is reduced to trivalent chromium (CR3); and CR3 is precipitated as chromium hydroxide.

Industry:Electrical and Electronics

Removal of free oil and grease from a wastewater stream reduces the potential for equipment problems to occur further downstream. There are three forms of oil encountered in wastewater treatment at a refinery.

Sour Water is the wastewater that is produced from atmospheric and vacuum crude columns at refineries. Hydrogen sulfide and ammonia are typical components in sour water that need to be removed before the water can be reused elsewhere in the plant. Removal of these components is done by sending the sour water from the process to a stripping tower where heat, in the form of steam, is applied.

Power plant boiler houses designed to burn coal or high sulfur oil are required by Federal and State pollution regulations to "scrub" (remove) sulfur dioxide from flue gasses to meet emission limits. SO2 in flue gasses is known to be harmful to the environment, as it is one contributor to the formation of acid rain. pH control is critical for the proper functioning of the scrubber system.

In flue gas desulfurization systems that use magnesium hydroxide (Mg(OH)2) slurry, the consumption of the desulfurization agent (Mg(OH)2) is controlled by using online pH analyzers. A great concern in the pH measurement is heavy staining of the pH electrodes by the Mg(OH)2 slurry. To ensure accurate measurement, frequent cleaning of the electrodes with an acid is required, adding to both maintenance workload and cost.

Industry:Chemical, Power

To defray energy costs, many industrial plants have their own boilers to generate steam in order to produce a portion of their energy needs. In addition to generating power, the steam may also be used directly in plant processes or indirectly via heat exchangers or steam jacketed vessels.

To technology in iron & steel industry is continuously improved to obtain the best possible performance. The improved plant performance gives rise to the higher quality improvement and lower cost, and simultaneously environmental friendly plant operation.

Fish perform all their bodily functions in water. Because fish are totally dependent upon water to breathe, feed and grow, excrete wastes, maintain a salt balance, and reproduce, understanding the physical and chemical qualities of water is critical to successful aquaculture. To a great extent water determines the success or failure of an aquaculture operation.

In stable dispersion of fine particles is the pre-requisite for the selective flocculation technique involving separation of ultra-fine valuable particles from the gangue. Among mineral processing techniques selective flocculation technique is known to have outstanding potential of capturing the particles of particular mineral in slurry of mixed mineral system by selective adsorption of water soluble polymers known as flocculants.

Downloads

Brochures

- FLXA402 4-Wire Liquid Analyzer, SA11 SENCOM Smart Adapter (2.9 MB)

- SENCOM 4.0 Platform (4.3 MB)

Instruction Manuals

- ST401G Sampling System (5.4 MB)

- WTB10-DO□ Terminal Box (696 KB)

General Specifications

- FLXA402 4-Wire Converter (1.5 MB)

Technical Information

- SENCOM 4.0 Platform: Grounding (3.6 MB)

- FLXA402 4-Wire Converter HART Communication (1.0 MB)

- FLXA402 4-Wire Converter MODBUS Communication (693 KB)

- Conductivity Analyzer Guide (992 KB)

- Contacting Conductivity sensor selection guide (1.6 MB)

Certificates

- FLXA402 FM (288.9 KB)

Drawings

- FLXA402 4-Wire Converter (603 KB)

기술 및 솔루션, 요꼬가와에 대한 자세한 정보를 찾고 계십니까?

견적 및 기술문의

Expert Guide: 원활한 작동을 위한 터치 패널 디스플레이

Expert Guide: 원활한 작동을 위한 터치 패널 디스플레이