Para un observador casual, una planta de refinería bien administrada por las soluciones VigilantPlant de Yokogawa, se ve "silencioso y aburrido", una frase usada por Peter Drucker. La rentabilidad de la planta se maximiza. Los sistemas de automatización ayudan al personal de la planta a administrar los conocimientos operativos, aumentan la productividad y cumplen con los reglamentos de salud, seguridad y ambientales. La información en su contexto se entrega en forma clara a las personas adecuadas en el momento adecuado, dando al personal responsable la previsión para hacer frente a acontecimientos con calma y de manera eficiente. Las soluciones VigilantPlant ayudan a todas las empresas de refinería a obtener una planta "silenciosa y aburrida".

Desafíos

El reto de los clientes

Las operaciones que se basan en el conocimiento en las refinerías, como el arranque y el cierre de la planta, el arranque del compresor y el cambio automático del tanque de crudo aún requieren un manejo manual por parte de un gran número de operadores. Por ejemplo, una transferencia de cambio automático de crudo eficaz a menudo requiere que se ejecute un conjunto completo de operaciones, incluyendo arrancar y parar motores, abrir y cerrar válvulas, medir flujos y descargar, en una secuencia específica decidida únicamente por los operadores con más experiencia.

Además, puesto que llegará un momento en que los operadores se retiren o renuncien, es necesario conservar sus conocimientos y mejores prácticas y transmitirlos de manera precisa a los operadores menos calificados. Esto es decisivo para maximizar la eficiencia de la producción y para evitar o eliminar los cierres que podrían ocurrir a consecuencia de una mala operación.

Nuestras soluciones

Al usar Exapilot, la solución de automatización basada en conocimientos de Yokogawa, los conocimientos y las mejores prácticas de la operación se pueden formalizar, administrar y configurar en un diagrama de flujo de procedimientos estandarizado. Este método estandarizado no solo permite la automatización al 100 % de complicadas operaciones, sino que también garantiza que la valiosa experiencia se transfiera y ejecute de manera precisa cada vez que haya un cambio de operadores o una diferencia en su nivel de habilidad.

Beneficios de los clientes

Uno de nuestros clientes, un importante productor y distribuidor de aceites, lubricantes y productos petroquímicos en Japón, estima que la introducción de Exapilot en uno de sus centros experimentales redujo las horas hombre hasta en 2000*.

El reto de los clientes

En una refinería se pueden lograr ahorros en energía instalando centros altamente eficientes y operándolos de manera más eficiente. Yokogawa tiene soluciones que ayudan a las compañías a mejorar la eficiencia y reducir el consumo de energía.

Nuestras soluciones

Desde la crisis del petróleo en la década de 1970, la industria de las refinerías en Japón ha hecho frente a precios de los energéticos cada vez más altos y estrictas regulaciones reduciendo el consumo de energía y disminuyendo las emisiones de CO2. Los operadores de las refinerías han logrado lo anterior introduciendo algunas de las tecnologías más avanzadas del mundo, y para ello han contado con el apoyo de los sistemas, soluciones y capacidades de ingeniería de Yokogawa. Yokogawa ha participado en más de 1000 proyectos de refinerías y se ha forjado una sólida reputación en esta industria. La compañía suministra soluciones que ahorran energía a través de un aumento en la eficiencia.

1. Visualización del consumo de energía y gestión de indicadores clave de desempeño (KPI)

Para ahorrar energía y reducir las emisiones de CO2 en las refinerías, habrá de visualizarse claramente el estado de las emisiones y el consumo de energía. Yokogawa ofrece una gama completa de soluciones como sensores de campo y sistemas de gestión de la producción que se apoyan en las tecnologías más recientes para monitorear y gestionar los parámetros relativos a la energía.

- Visualización a través de la gestión de la operación

- Visualización a través de la gestión de la producción

- Visualización de datos de campo

2. Reducir el % de O2 excesivo en gases de chimenea de hornos/calderas

Cuando hay un exceso de oxígeno (O2) en los gases de chimenea, el resultado es una combustión incompleta. Usualmente, el O2 se mantiene dentro del 1.5 al 2 % del nivel óptimo, pero se ha demostrado que la tecnología de detección con láser puede mejorar la velocidad y la fiabilidad de las mediciones de CO/O2/CO2 y propician reducciones aún mayores en exceso de O2, dando como resultado ahorros adicionales de energía.

Tecnología instrumental

El nuevo TDLS8000 de Yokogawa integra todas las funciones principales de la industria en un dispositivo robusto. El diseño de la plataforma es para mediciones in situ que descartan la necesidad de extracción y acondicionamiento de muestras. El sensor sin contacto permite una variedad de tipos de procesos, incluyendo corrosivos, abrasivos y de condensación.

El reto de los clientes

La mezcla del petróleo es el último paso en el proceso de convertir el petróleo crudo en productos terminados como la gasolina. Al usar tecnologías de mezcla tradicionales como mezcla en el tanque y mezcla en proporción, las refinerías tienen a usar cantidades excesivas de aditivos para garantizar que el producto de gasolina cumpla las especificaciones mínimas impuestas por los organismos reguladores. Sin embargo, debido al alto costo de los aditivos para la mezcla, se requiere una solución de mezclado que pueda reducir las regalías de calidad y cumplir las especificaciones mínimas.

Nuestras soluciones

Yokogawa ofrece un sistema de optimización de mezcla, o una solución de Control de propiedades de mezclas (BPC), que calcula las proporciones de mezcla óptimas en tiempo real, con base en valores medidos mediante continuos análisis en línea de propiedades del producto arrojados por un analizador NIR, y modifica automáticamente los puntos de ajuste del controlador para ajustar en forma automática las proporciones de mezcla en línea.

Además de la solución BPC, Yokogawa también puede proveer soluciones remotas completamente integradas que cubren todas las operaciones de procesos remotas como sistemas de movimiento de petróleo (OMS), sistemas de información de laboratorio, sistemas de analizador y sistemas de programación/planificación.

Beneficios de los clientes

Los siguientes son testimonios de los clientes sobre los beneficios que se pudieron obtener al usar el BPC de Yokogawa y otras soluciones remotas:

- Mayor seguridad: el sistema guía y supervisa la seguridad de las operaciones de área remotas.

- Calidad del producto mejorada: la supervisión del sistema minimiza la probabilidad de que ocurran errores operativos que pueden causar contaminación del producto.

- Desempeño ambiental mejorado: el control de movimiento por el OMS resuelve problemas ambientales que podrían ser causados por rebosamiento del tanque y otros factores.

- Aumento de la eficiencia operativa: el número de operaciones llevadas a cabo por cada persona se reduce al mínimo a través de la motorización de válvulas y la capacidad de consultar el aislamiento existente para los trabajos en espera.

- Percepción espacial más extensa: la percepción total del área está disponible para todos los operadores y se mantiene actualizada de manera permanente en la base de datos del sistema.

Detalles

Yokogawa tiene experiencia en aproximadamente 1000 proyectos en el sector de refinación, que le han valido una alta credibilidad a la compañía por parte de los refinadores.

Diseño e ingeniería

Servicios de Ingeniería y diseño de front‐end (FEED), Proveedor principal de instrumentación (MIV)

Instalación y puesta en servicio

Ingeniería en la obra, Pruebas de ingeniería, Servicios llave en mano

Operación y optimización

Consultoría en optimización, Soporte de operación 24/7, Soporte de diagnóstico en línea

Mantenimiento y modernización

Optimización de activos, Modernización en línea, Soporte en soluciones de ciclo de vida

Renovación y expansión

Expansión en línea, Migración en caliente

Recursos

Yokogawa provided a Dynamic Real-Time Optimizer (RT-OP) to optimize the operations of the hydrocracker unit at Aramco Riyadh Refinery.

By dynamically calculating optimal setpoints, the RT-OP optimizes operations beyond the APC system.

- This has considerably improved the safety, quality, and efficiency of off-site operations.

- Yokogawa was the clear choice for installation of the OMS.

- El CENTUM CS 3000 juega un papel clave en los aceites de desecho de Malasia del proyecto de diésel.

- Yokogawa propone suministrar sus sistemas y servicios como el proveedor principal de instrumentos.

- Flawless refinery start-up assured by operator training simulator.

- The virtual test function of the OmegaLand simulator created the same environments as CENTUM CS 3000.

- To replace the existing CENTUM XL control station with the latest Yokogawa CS 3000 hardware and upgrade the control network.

- The plan was to minimize plant downtime by doing a hot cutover from the old to the new control system.

- Smooth and safe switchover to the new system

- Easy-to-use, easy-to-engineer system, plus various post-installation enhancements

- Tuned controllers for smooth plant operation and better traceability of process upsets

- Various other improvements thanks to advanced process control and MVC implementation

- Exapilot was introduced to maximize operational efficiency at an experimental refining facility.

- To prevent operator errors, it was essential to standardize operating procedures.

- Computerized Maintenance Management System by PRM and SAP Schedules Field Instrumentation Maintenance.

- The frame applications and DTMs support the preventive maintenance strategy with self-diagnostic and condition monitoring.

PetroChina Guangxi Petrochemical Company has completed construction of a combined refinery and petrochemical production complex in Qinzhou, a port city in China's Guangxi Autonomous Region. With a 10 million ton per year capacity, the refinery is one of China's largest, and is truly world class, using a highly advanced hydrogenation process, with the main process technologies coming from the USA and France.

- To decrease downtime and maintenance costs, the decision was made to introduce Yokogawa's CENTUM DCS.

- With well-experienced MAC approach, Yokogawa replaced successfully legacy DCS.

La refinería Mathura es una instalación de gran importancia estratégica que suministra diésel, gasolina, combustible para turbinas de aviación, queroseno, gas licuado de petróleo, fueloil, y el asfalto de petróleo a clientes de todo el noroeste de la India.

- Successful migration of in-line blending distributed control and oil movement systems.

- To minimize operator intervention and to keep the product properties on specification.

- Smooth project execution with no schedule and/minimal safety incidents.

- Easy to use, easy to reconfigure interface that has resulted in numerous post-installation enhancements.

- Minimizing day-to-day plant operation problems including reducing the alarming factor.

- The project goals emphasized schedule, quality, cost and safety.

- More than 40 sub-system interface cards are utilized for b14 partners company7s system integrated with CENTUM CS 3000.

- Exapilot smoothly starts up and shuts down the world's biggest experimental distillation unit.

- Data visualization is the key, giving operators a complete understanding of what is is going on in the process, in real time.

- Integrando los sistemas CENTUM VP y ProSafe-RS garantizan una Operación Ininterrumpida de los procesos ADU/DKU.

- "¡Este es un verdadero VigilantPlant! Vamos a seguir mejorando nuestra eficiencia de producción."

- Exapilot contributes to safety, reduces cost, and retains operational know-how.

- Using the CENTUM CS 3000 system, many kinds of plant key performance indexes are calculated and analyzed to produce further improvements.

- During plant start-up, PRM helps the customer's engineers perform all the loop checks.

- La refinería AR1 recientemente reemplazó su DCS Legacy con el CENTUM CS 3000 de Yokogawa.

- Completar con Éxito un Sistema de Movimiento Inteligente del Petróleo.

- HMEL seleccionó una solución integrada de Yokogawa

- Yokogawa India supervisó e implementó la ingeniería, instalación y puesta en marcha de la refinería.

- Yokogawa successfully carried out the upgrade of off-site system in a 48 hour shutdown period with Seibu Oil.

- Control room design for HSE and smooth communication contributes to the operational efficiency and safety.

- This is the first project in which Shell Global Solutions US has used a contractor outside of Shell for its Advanced Process Control implementation

- The post implementation study shows that the overall Delayed Coker APC controller returns a benefit which is almost three times the original promise.

- The Advanced Process Control application on the GOHT unit helped control the plant with less variation during Coker drum switch and with less operator interactions and minimized giveaway.

- A post-implementation study estimated that the overall GOHT Unit APC controller returns a savings about 198% greater than the originally estimated.

Operators must receive diagnostic information before a line block leads to a malfunction. Yokogawa provides predictive diagnostics based on trend analysis of the blocking factor, which improves maintenance efficiency and reduces maintenance costs.

La configuración del transmisor de nivel puede tomar mucho tiempo. Los transmisores DPharp tiene la función de un software avanzado eliminando esta tarea que toma tiempo. Con talleres de mantenimiento cada vez más pequeños, la búsqueda de equipos que nos permiten hacer más con menos se convierte en una prioridad.

Recientemente, las legislaciones de contaminación del aire, como la Ley de Aire Limpio para reducir la cantidad de contaminación del aire están aumentando en todo el mundo. La Ley de Aire Limpio aborda numerosos problemas de la calidad del aire. Uno de estos problemas es la lluvia ácida causada por las emisiones de dióxido de azufre y las emisiones de óxidos de nitrógeno de las centrales eléctricas alimentadas con combustibles fósiles y otras fuentes industriales y de transportación.

La industria de la refinación del petróleo hoy en día se enfrenta a las regulaciones cada vez más estrictas que dictan tanto la calidad de sus productos como la actividad de sus procesos de producción. Como pionero de la tecnología de medidores de flujo Vortex, el desafío de Yokogawa es traer soluciones innovadoras de medición de flujo para los usuarios en varias industrias de proceso continúa hasta el día de hoy.

Enhance the efficiency and safety of your vapor recovery systems and flare/vent headers with Yokogawa's cutting-edge Tunable Diode Laser Spectrometers – the TDLS8000 and TDLS8220. Elevate your oxygen measurement capabilities with our interference-free analyzers, providing direct measurements. Experience unparalleled reliability, ensuring minimal upkeep and secure operations without the need for system shutdowns.

The top gas generated at the top of a distillation column in a petroleum refinery's fluid catalytic cracker (FCC) is used to produce gasoline and LPG. The GD402 Gas Density Meter features an intrinsically safe and explosion-proof design, fast response, and a dust-proof, anti-corrosive, and flame-proof construction.

In limestone-gypsum flue gas desulfurization systems, the consumption of a desulfurization agent (lime) is controlled using online pH analyzers.

Heat exchangers are devices that provide the flow of thermal energy between two or more fluids at different temperatures. Heat exchangers are used in a wide variety of applications. These include power production; process, chemical and food industries; electronics; environmental engineering; waste heat recovery; manufacturing industry; and air-conditioning, refrigeration, and space applications. Yokogawa offers a means to control heat exchanger leakage and prevent costly maintenance, repair and downtime with an easy-to-use, virtually maintenance-free condensate conductivity measurement method.

Fired heaters are used for various processes in oil refining and petrochemical plants.

Wireless temperature measurement solution makes modernizing operations and maintenance of delayed coker unit affordable.

Ion Exchange is a method for the exchange of ions between two electrolytes or between an electrolyte solution and a complex molecule. In most cases the term is used to denote the processes of purification, separation, and decontamination of aqueous and other ion-containing solutions with solid polymeric or mineralic ion exchangers.

Challenges

- The distance is not so long, but there are many pipes and tanks ("Pipe Jungle") in the field.

- Had to avoid the obstacles and take care multi path condition.

Solution

Repeater is installed on high place between control room and monitor position. The extend cable is used for antenna of Gateway.

- Temperature Transmitter (YTA) x1, Pressure Transmitter (EJX) x2

The U.S. refineries represent approximately 23 percent of the world's petroleum production, and the United States has the largest refining capacity in the world. Petroleum refining is an industry, which is undergoing intense amounts of scrutiny in the United States from regulatory agencies and environmental groups.

Yokogawa's Data Aquisition Temperature Uniformity Survey enable heat-treaters to produce accurate records of TUS, instrumentation and thermocouple calibration certificates.

In this eBook we explain how to improve fired heaters safety & efficiency by controlling combustion using TDLS technology. Download it now and learn:

- The 4 top industry challenges related to fired heaters

- How to efficiently and safely manage combustion

- How TDLS technology can improve operational excellence in fired heaters

Download this eBook and learn:

- The top challenges that drive reinstrumentation

- How to plan for and achieve a successful project

- Best practices in identifying your project scope

- 5 ways to improve operator effectiveness

- Different scenarios and best practices for updating, migrating or replacing process controls, safety systems, and instrumentation in plants

A multivariable model based predictive control (MPC) was implemented at the FCCU "A" in YPF S.A. Refinería La Plata.

There are three MPC controllers installed: one covering the reactor-regenerator-main fractionator, other controlling the gas con- centration plant ant the third controlling an isolated depropanizer column. The paper describes the implementation of the project, the controller structure and the main results obtained from the MPC.

Visual MESA© is a steam system optimization and management computer program that was originally developed at Chevron and now marketed by Nelson & Roseme, Inc. Visual MESA is currently used at refinery and chemical manufacturing sites to optimize the overall site steam system and the parts of the electrical system that economically trade off with the steam system.

This paper will explore significant optimization variables and constraints commonly encountered in refinery steam system optimization, the strategies Visual MESA uses to deal with them.

Hydrogen management can have a significant effect on refinery utility supply through the integration with the rest of the utilities. Real-time optimization of hydrogen production in conjunction with steam, power and fuels can yield significant savings opportunities for the refinery.

This paper describes the tasks performed to develop and implement real time, online models, to help with the three KNPC refineries energy cost minimization and energy management, which are scheduled to perform it automatically. They allow to clearly identify the different economic trade-offs that challenges the operation of the site wide energy systems at minimum cost while reducing the energy waste and, therefore, CO2 footprint. Recommendations given by the optimizers are taken into account by operations on a daily basis

In general, refineries exhibit a very good potential for real time monitoring and optimization using Visual MESA Energy Management System.

Based on our extensive experience, overall benefit in the range of 2% to 5% of the total energy cost can be achieved. Expected project payback is always less than one year.

This article describes the tasks performed to develop and implement a real time, online model for energy cost minimisation and energy management at KNPC's MAA refinery.

After a description of the main project implementation tasks, the Real Time Energy Management System's (RTEMS) functionalities are described and the optimisation implementation procedures are commented on. Finally, several obtained results are presented.

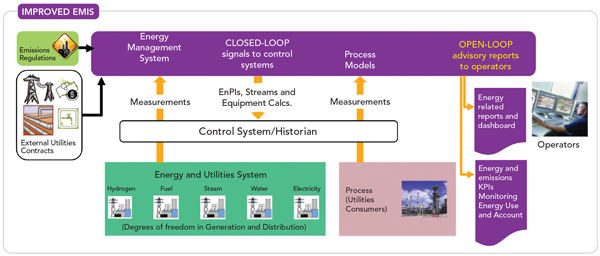

Utilities and energy systems are often the major source of SOx, NOx and CO2 emissions, therefore, emissions control and the management of credits and quotas are tightly interrelated with energy management.

In the case of refineries, chemical and petrochemical plants, energy represents the main cost (second to feedstock) and therefore its reduction has become a bottom line business decision. The energy systems at these sites are inherently complex, with the emissions cost analysis and limits compliance introducing an additional factor to the complexity of the energy costs reduction challenge.

Process plants use different type of fuels, they often operate cogeneration units, their steam networks consist of several pressure levels, there are different types of energy consumers and there are emission limits to be observed. Import or export of electricity in deregulated markets, which could also be traded off with more or less CO2 and other contaminant gaseous emissions, increase the optimization problem complexity.

The Repsol YPF Tarragona Refinery operates a large, complex steam system. Utilities Optimization has been performed with an on-line computer based steam management program (VISUAL MESA) in order to make the Refinery more energy efficient and reduce steam system operating costs.

VISUAL MESA allows operators and engineers to:

- Monitor steam production and use;

- Optimize the production and use of steam, fuel and power in order to reduce costs;

- Perform "what-if" studies, and

- Audit the system with continually validated data. Nelson & Roseme, Inc. and Soteica Europe S.L. have worked with Repsol YPF Tarragona

Petronor is Spain's largest refinery, with a processing capacity of eleven million tons a year. Its energy system is large and complex, therefore the auditing and control of energy costs are a real challenge. This paper describes the tasks performed together with Soteica, using a modern on line information and optimization system tools, to reduce energy costs.

This paper will not describe just all the features of the software or fully explain on-line optimization technology. The objective of this work is to present some interesting facts and lessons from the experience of implementing a cost based optimization program at thirty oil refineries and petrochemical complexes, around the world, since 1997. This paper will focus on the key optimization variables and constraints in steam system optimization, how they should be handled and how the human and organizational aspects can be addressed.

A detailed model of the steam, fuels, electricity, boiler feed water and condensates systems has been built, including all the interactions between these systems, real plant constraints and degrees of freedom of their operation. Such a model is scheduled to perform automatic executions of the optimization of the entire system and is continually populated with validated live data from the process. A calculation of equipment efficiencies is done as part of the performance monitoring activity of the model. Other monitoring aspects include the continuous auditing of the energy system so the data can be relied on for evaluating the value of energy production and usage, and waste can be reduced or eliminated.

Industrial facilities where power and steam is produced (i.e., Cogeneration) exhibit a very good potential for real time monitoring and optimization using Visual MESA Energy Management System.

Based on our extensive experience, overall benefit in the range of 2% to 5% of the total energy cost can be achieved. Expected project payback is always less than one year.

Visual MESA was successfully applied to many industrial facilities worldwide, several of them operating steam and power generation networks of different complexity and capacity but all with energy cost savings.

This paper discusses real industrial examples in which the sitewide utilities system of refinery and petrochemical Sites are optimized with a real time, on line, industrially proven software. Experiences gained during more than 20 years of industrial projects deployed worldwide are commented (Refs. 1 to 10 are related to some recent projects). Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper.

This paper describes the tasks performed, together with Soteica, using modern on line information system tools to assist with the energy system management.

After a feasibility study, TOTAL decided to test an on-line model for site wide energy system management. TOTAL operates a large and complex energy system at Feyzin refinery. A detailed model of the energy system has been built and it is continuously fed with validated (not reconciliated), real-time data. It includes all the actual constraints of the site and decision variables for their operation. Continuous performance monitoring is also done, since the model writes back its results to the Real Time Data Base (Plant Information system). It also provides reliable data that helps to audit the energy productions and usages within the site energy system, and in that way wastes can be detected and eliminated.

An online steam management program can help refineries manage their steam and utility systems more energy efficiently and reduce their operating costs through optimisation and monitoring

Big and complex industrial facilities like Refineries and Petrochemicals are becoming increasingly aware that power systems need to be optimally managed because any energy reduction that Operations accomplish in the producing Units could eventually be wasted if the overall power system cost is not properly managed. However, process engineers always attempted to develop some kind of tools, many times spreadsheet based, to improve the way utilities systems were operated. The main drawback of the earlier attempts was the lack of data: engineers spent the whole day at phone or visiting the control rooms to gather information from the Distributed Control System (DCS) data historian, process it at the spreadsheet and produce recommendations that, when ready to be applied, were outdated and not any more applicable.

Utilities and energy systems are often the major source of SOx, NOx and CO2 emissions, therefore, emissions control and the management of credits and quotas are tightly interrelated with energy management. In the case of refineries, chemical and petrochemical plants, energy represents the main cost (second to feedstock) and therefore its reduction has become a bottom line business decision. The energy systems at these sites are inherently complex, with the emissions cost analysis and limits compliance introducing an additional factor to the complexity of the energy costs reduction challenge.

Repsol Cartagena was the first oil refinery to be built on the Iberian Peninsula. It has an annual crude distillation capacity of 5.5 million tonnes, with two main areas of production: fuels; and lube oils, asphalts and paraffinic and aromatic oils. Repsol Cartagena is currently involved in an ambitious expansion project, whereby 22 new units will be built, increasing its refining capacity to an annual 11 million tonnes.

The energy systems, the steps for the implementation of Visual MESA and several features of the model are described in this article, with a focus on the use of the software for the calculation of energy-related KPIs. The EMS implementation project is discussed and the main conclusions relative to the reduction in operating costs are also presented.

This paper shows real industrial examples in which, with the existing equipment, continuous CO2 emissions reductions were achieved while optimizing the energy systems by using an on line model. The importance of including the cost of CO2 emissions and how it should be taken into account when managing energy systems is explained. Furthermore, the optimization model is useful to perform case studies to evaluate energy system modifications taking into account this aspect.

This paper describes the tasks performed together with Soteica, by using an on-line model, to help achieve site wide energy costs minimization. A detailed model of steam, fuels, electric, boiler feed water and condensates system has been built, contemplating all the real constraints and degrees of freedom for their operation. The electric power system is also modelled as it interacts with the steam production and usage. Such a model is continually validated with live data. A continuous calculation of equipment efficiencies is done as part of the performance monitoring activity of the model that is running as a service.

A refinery energy system is modelled, including all the constraints, with continuous model validation using live data. Performance monitoring includes the tracking of equipment efficiencies by utilising validated data for its continuous calculation,

Experiences gained during more than 20 years of industrial projects deployed worldwide are commented. Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper. Open loop vs Closed loop implementation is also presented.

Rohm and Haas Company is one of the world's largest manufacturers of specialty materials, including adhesives, sealants, coatings, monomers, electronic materials, inorganic and specialty solutions, and ion exchange resins. Founded in 1909 by two German entrepreneurs, Rohm and Haas has grown to approximately $6 billion in annual revenues.

Alarm management is not just a project that has a start and end date; it's a continuous cycle. Once the alarm system has been reviewed and improvements have been identified, we must check that controls are in place to ensure the alarm system remains functional. The key is to ensure that the system is continuously monitored and any changes are fully documented. There are seven key steps for alarm management. Rationalization is one of those critical steps.

This paper shows how to improve distillation operations by focusing on procedure automation. It will review the importance of using procedures in distillation operations and highlights the collaboration work underway between Fractionation Research Inc. (FRI) and Yokogawa Corporation to improve procedural operations.

The worlds of process automation and production management have been converging for some time. What once used to be islands of automation and production management functionality connected through highly proprietary integration schemes that were costly to maintain have developed into integrated platforms that provide seamless data exchange between the world of automation and the plant floor, the functions of production and operations management, and integration with business level systems.

The world of process automation is governed by procedures. While we like to refer to the process industries as being largely "continuous", this could not be further from the truth. Process manufacturing is constantly in flux.

From engineering to installation, commissioning, operations, and maintenance, FOUNDATION fieldbus offer significant cost reductions of 30 percent or more versus conventional analog systems. Many of these cost reductions come from the advanced functions that fieldbus offers versus analog technology.

The automation suppliers that will be successful in the long term will be those that effectively address application or industry specific problems for end users with a value proposition that cannot be ignored. These problems exist throughout the process industries today, and they won't be solved by simply offering a product, but through a combination of hardware, software, services, application expertise, and knowledge.

In ARC's view, customers need a compelling business value proposition to justify investment in any kind of automation. Vigilance and VigilantPlant were created with this in mind. Yokogawa's vision with VigilantPlant is to create an environment where plant personnel and operators are well informed, alert, and ready to take action.

Yokogawa ha recorrido un largo camino en hacer que su mensaje sea claro en el mundo de la automatización de procesos. El año pasado, la compañía se embarcó en una campaña global de marketing a gran escala para que los clientes conocieran el enfoque de la compañía en la confiabilidad del sistema, su seguridad, constancia y durabilidad. Denominado "Vigilancia", la campaña creó un mensaje unificado para la empresa y en gran medida ayudó a aumentar la difusión de la marca Yokogawa y la filosofía de la empresa.

Los usuarios finales de procesos automatización están bajo más presión para hacer más con menos. La situación económica actual hace que muchos proyectos de capital de automatización estén en espera. Con los presupuestos de capital más limitados que nunca, los usuarios en lugar de enfocarse en los presupuestos de operaciones (en donde también la reducción de costos es una preocupación clave), o en las inversiones de automatización con un rápido retorno de inversión.

In today's dynamic industrial marketplace, the only constant is change. Raw material costs, energy costs, market demands, environmental and safety regulations, technology, and even the nature of the labor force itself are constantly changing, and not always in predictable directions.

Environmental pollution caused by volatile organic compounds (VOCs) has become a global environment issue, including issues on effects upon health. This paper introduces a system based on detection and sampling technologies and developed for measuring goes in the global environment. Small amounts of VOCs are measured with a gas chromatograph or photoionization detector (PID). VOCs in water are sampled using a sparging method. A small quantity of VOC constituents of more than 20 different types can be measured with a gas chromatograph using a programmed temperature oven. The PID can detect a ppb level of VOCs that are ionized using a vacuum ultraviolet radiation lamp. We expect these devices will be useful for improving the global Environment.

With fired heaters, users hope to get greater efficiency and reduced emissions but often are disappointed. Given the number of fired heaters operating every day and their importance in the process industries, any improvements realized across the board will have huge impacts. More units can reach their potential with some simple changes in work practices and technology upgrades.

La migración de DCS de una refinería proporcionó una oportunidad para volver a configurar y consolidar las salas de control y sistema de administración operativo.

July 2011

Process plants are run according to operational procedures. These procedures consist of a set of tasks that are executed in a consistent manner to achieve a specific objective, such as starting up, shutting down or transitioning a unit as part of making a product.

Abril/Mayo 2007

El sistema instrumentado de seguridad ProSafe-RS de Yokogawa (SIS) será el núcleo de un nuevo sistema de seguridad contra incendios y gas en la refinería de Shell Clyde (NSW). El contrato incluye el sistema de control, ingeniería de sistemas y la instalación y supervisión.

Process automation in oil refineries is undergoing major changes, driven by customers frustrated by what they consider to be slow and incremental advances from the main automation original equipment manufacturers (OEMs) in the industry. ExxonMobil has become a de facto industry representative and is driving vendors like Yokogawa and others to reevaluate how large-scale automation projects are implemented.

Using wireless technology for monitoring a variety of measuring points in Industrial Plants has becoming a very attractive choice for plant managers. Today, the plant manager is able to build a quick and cost effective network solution to enable flexible information acquisition and to improve maintenance efficiency and safety.

Visual MESA Systems empower improved operational efficiencies in real time

Machines don't panic and they always do what they're told. But they can't think on their feet and can't react to situations for which they have not been programmed. Which do you want to depend on when your life depends on it?

CONTROL, January 2013

Standard Automation Methodology Improves Operations and Prevents Incidents by Enabling the Sharing of Best Practices Among Operators.

ARC believes that by implementing procedural automation, many process plants can minimize variability to help ensure smooth, efficient, and safe state transitions.

The global refining industry is constantly evolving and responding to new crude supplies and sources, more stringent fuel/product specifications, perpetually changing demand patterns and other global and regional trends. Increased competition from large, efficient refineries is forcing small- to mid-sized refiners to rethink their strategies to remain competitive.

Increasing oil prices are reducing the relative feedstock and energy costs advantages refiners and petrochemicals producers have recently enjoyed. Allied with the high cost and growing scarcity of skilled staff, a fundamental shift in mindset towards plant operations and maintenance is required to assure organizational resilience. Therefore, the desire to achieve enhanced cost structures through innovation in operating models and digitalization has intensified.

Wiring temperature sensors installed in a chimney back to a control room can be challenging and expensive, so many plants and facilities are instead implementing wireless solutions, such as this Yokogawa YTMX580 8-input temperature transmitter.

Adding process considerations improves energy savings and production performance.

Documentos y Descargas

Catálogos

- Brochure: Five Mistakes When Selecting a Flowmeter

- Soluciones y Productos Yokogawa en Norteamérica (3.6 MB)

- Improved Combustion with TDLS - TDLS8000, TDLS8100, TDLS8200 Series (9.7 MB)

- Yokogawa Engineered Solutions for Ambient Air Monitoring (761 KB)

- Extractive Tunable Diode Laser Spectrometer TDLS8220 (5.6 MB)

- TDLS8220 LOC (Limiting Oxygen Concentration) Infographic

- Refining Solutions (12.5 MB)

- Yokogawa Performance Distillation Solutions

- Overcome Temperature Effects for DP Level (778 KB)

Videos

The YSS1000 setting software (hereinafter referred to as the YSS1000) is package software to configure the functions of the YS1000 series (hereinafter referred to as the YS1000) devices. Writing and reading of parameters and user programs of the YS1000, and PID tuning and monitoring of user programs can be performed through the use of communication.

How much do you know about pressure transmitters? Are you accurately, quickly and reliably measuring pressure? Ultimately, the drive of any good pressure transmitter is to get an accurate, reliable pressure measurement to the data user quickly. This video gives you the answers to your basic questions about pressure and pressure transmitters.

Sample systems are a crucial component of and have a significant impact on the performance of a process gas chromatograph analyzer. When working on sample systems, you must have a constant awareness of time delays. This fundamentals webinar will take the mystery out of lag times.

¿En busca de información adicional sobre Yokogawa Iberia, tecnología y soluciones?

Contáctenos